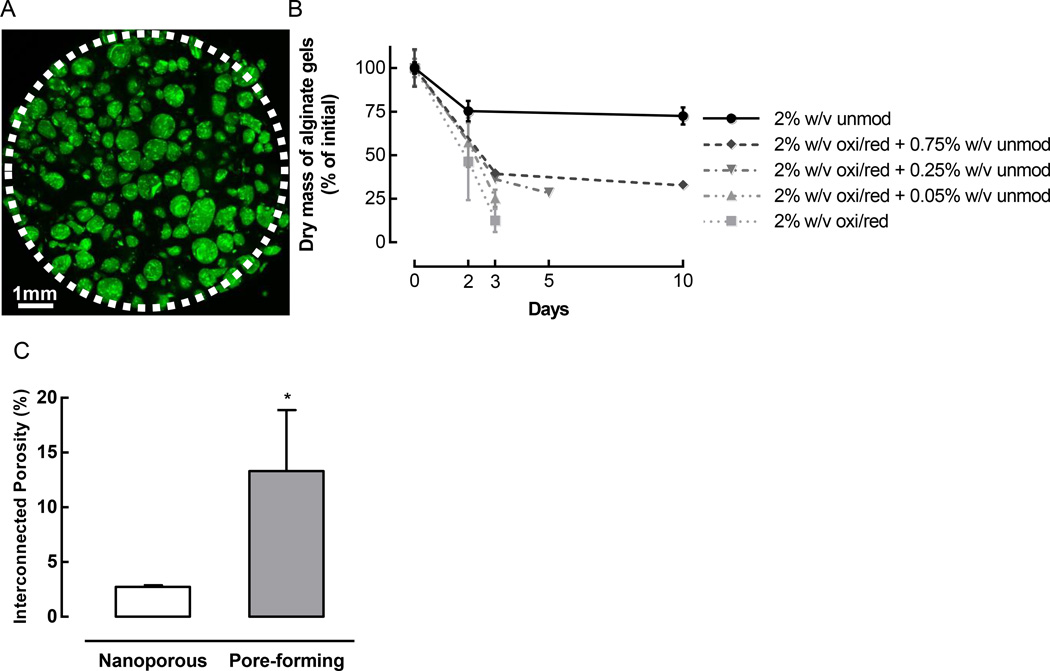

Figure 1.

Pore-forming hydrogels were created by incorporating rapidly degrading porogen beads into a bulk gel. (A) Confocal Z-slice of a pore-forming gel containing 50% v/v bulk gel (unmod alginate) and 50% v/v FITC-labeled porogen beads (green, fabricated using 2% w/v oxi/red + 0.25% unmod alginate). The white dotted line demarcates the border of the gel, which was sampled using a biopsy punch; some porogens at the edge of the gel were dislodged in the process of punching out the sample. (B) In vitro degradation kinetics of alginate gels consisting of 2% w/v unmodified (unmod) alginate, 2% w/v oxidized and reduced (oxi/red) alginate, or binary mixtures of oxi/red and unmod alginate. (n = 3; mean ± s.d. shown). (C) Interconnected porosity of nanoporous and pore-forming gels, as determined by a water wicking assay. Nanoporous gels consisted of 100% unmodified alginate, and pore-forming gels were composed of 50% v/v bulk gel (unmod alginate) and 50% v/v porogens (fabricated using 2% w/v oxi/red + 0.25% unmod alginate). (n = 4; mean ± s.d. shown; * p < 0.05).