Table 3.

Preparation of cyclic systems utilizing 15.[a]

| |||||

|---|---|---|---|---|---|

| Entry | NuLi | E+ | Quench | Product | Yield |

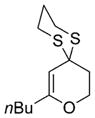

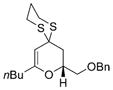

| 1 | nBuLi |

|

A |

41 |

68% |

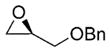

| 2 | nBuLi |

|

A |

42 |

69% |

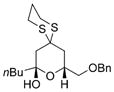

| 3 | nBuLi |

|

B |

43 |

72% |

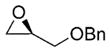

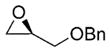

| 4 |

44 |

BnBr | B |

45 |

60% |

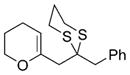

| 5 |

44 |

|

B |

|

64% |

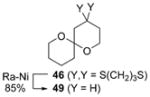

| 6 |

47 |

|

B |

|

67% |

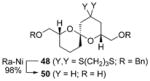

Reaction conditions: i) 15, Et2O, –78 ° C, then slow addition of NuLi; ii) BnBr, HMPA, Et2O, –78 ° C to –30° C; iii) quench A with sat. aq. NH4Cl or quench B with 48 % aq. HF, then NaHCO3.