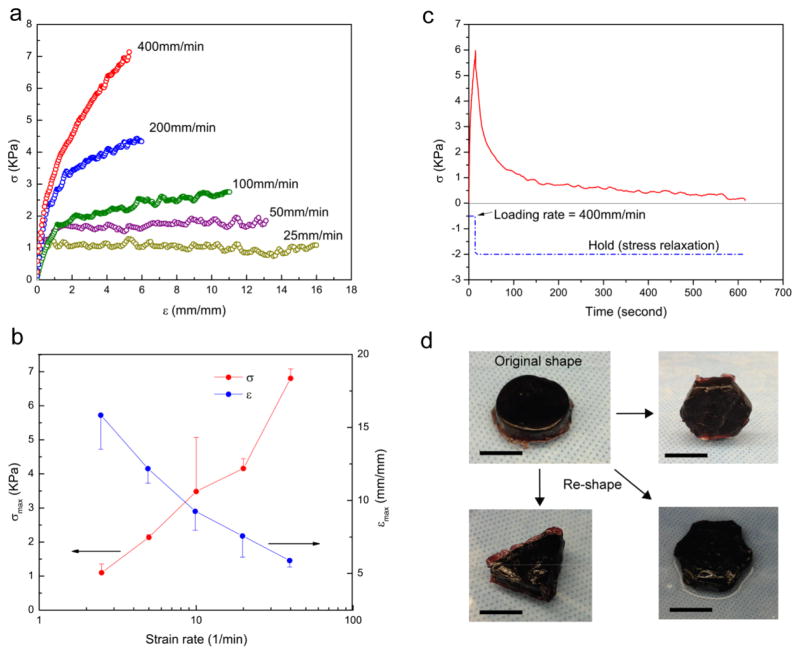

Figure 4.

The viscoelasticity and remoldable behaviors of the hydrogels (1xFe). (a) Tensile stress-strain curves of the hydrogels under different deformation rates from 25 to 400 mm/min. (b) Dependence of the tensile strength (maximum stress) and rupture strain on deformation rate. Increasing deformation rate results in higher strength and lower rupture strain (Error bars: SD, n=3). (c) Stress relaxation behavior of the hydrogel. (d) Re-moldable behavior of the hydrogel. A hydrogel disc is reshaped into triangle, hexagonal and flower-like shapes after being compressed into different PDMS molds (Scale bars: 10mm).