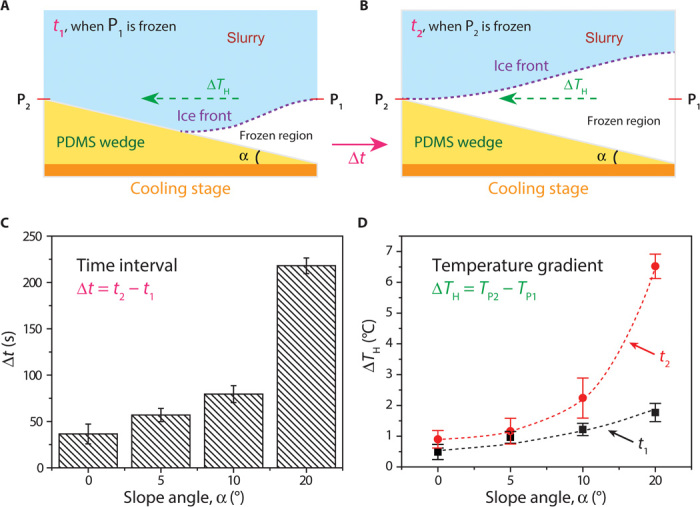

Fig. 5. Schematic illustration of bidirectional freeze-casting mechanism.

(A and B) PDMS wedges with slope angles α ranging from 0° to 20° were inserted between the slurry and the copper plate. Two thermocouple probes were placed on opposite walls of the mold at positions P1 and P2 corresponding to the height of the wedge. Times t1 and t2 correspond to the situations at which P1 and P2 get frozen, respectively. (C) As the slope angle was increased, the time interval Δt = t2 − t1 also increased, thereby demonstrating the gradient nucleation process. (D) The horizontal temperature gradient ΔTH (TP2 − TP1) corresponds to the difference of temperature between positions P1 and P2. At angles larger than 10°, a monodomain structure is created, with a significant horizontal temperature gradient observed at both t1 and t2.