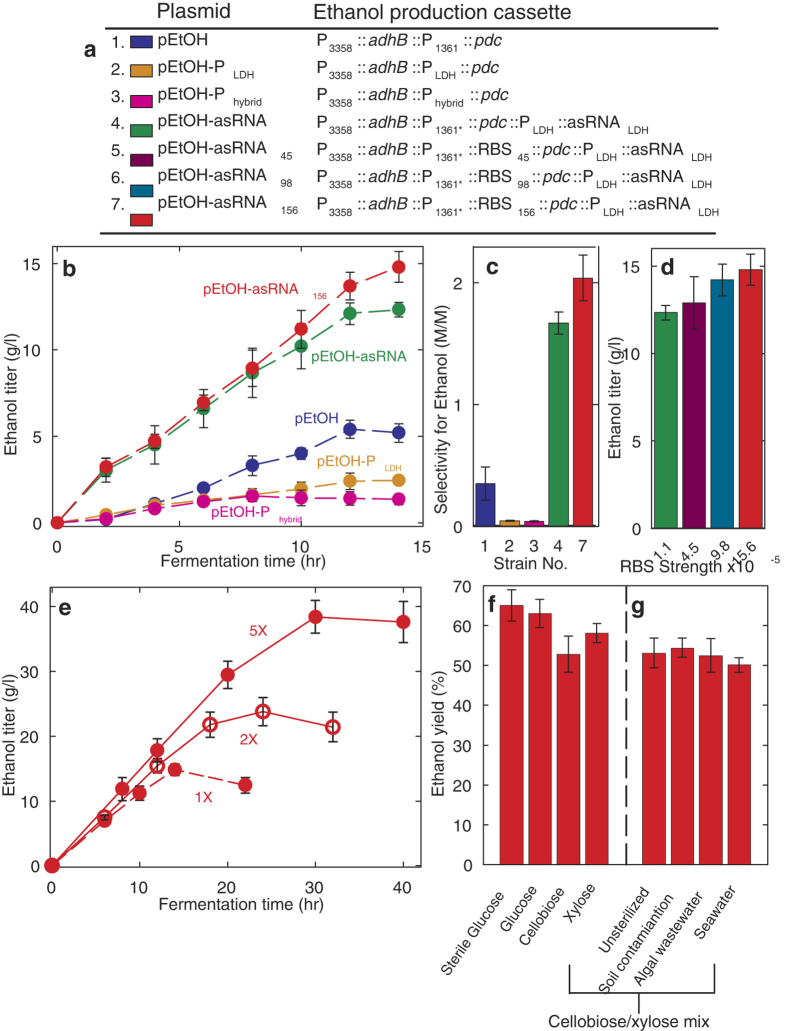

Figure 4. Engineering B. marmarensis for alkaline biorefining of complex carbohydrates in contaminated, wastewater medium.

(a) Strain genotypes for alkaline ethanol production. All plasmids used cat selection marker and repB origin from ref. 4. Phybrid was a fusion of P1361 and PLDH. P1361’ and Pldh’ had modified RBSs compared to their genomic counterparts. (b) Ethanol production of B. marmarensis strains from sterile glucose. Initial production with pEtOH reached 5 g/l and a 22% yield. Titers were bolstered with antisense RNA knockdown of lactate dehydrogenase (asRNALDH). (c) Selectivity for ethanol over lactate in engineered strains. Increasing ethanol titers coincided with less lactate. (d) Raising RBS strength of pdc increased flux of pyruvate towards ethanol. Production rose to 15 g/l, or 65% the theoretical maximum. (e) Ethanol titers were raised to 38 g/l by concentrating glucose and salts in the medium. (f) Engineered B. marmarensis converted unsterilized cellobiose and xylose with similar yields. (g) Production ethanol from cellobiose and xylose co-fermentation with soil contamination and in algal wastewater or seawater.