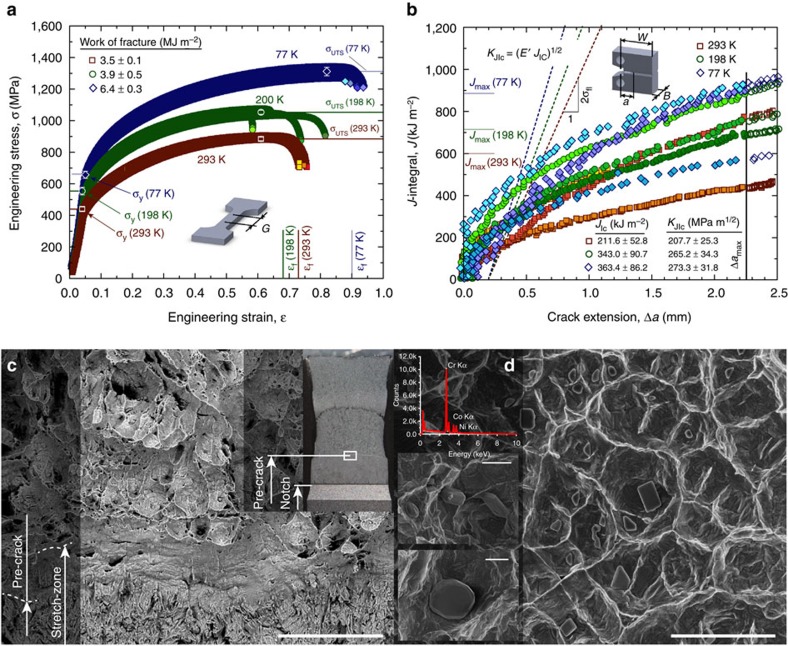

Figure 2. Mechanical properties and failure characteristics of the CrCoNi medium-entropy alloy.

(a) Tensile tests show a significant increase in yield strength, σy, ultimate tensile strength, σUTS and strain to failure, ɛf, with decreasing temperature from room temperature, 293 K, to cryogenic temperatures, 198 and 77 K. In the same temperature range, the work of fracture increases from 3.5 MJ m−2 to 6.4 MJ m−2. (b) Fracture toughness tests on compact-tension, C(T), specimens show an increasing fracture resistance with crack extension and crack initiation, KJIc, values of 208, 265 and 273 MPa m1/2 at 293, 198 and 77 K, respectively. (c) Stereo microscopy and scanning electron microscopy images show a clear transition from the notch to the pre-crack and a pronounced stretch-zone between the pre-crack and the fully ductile fracture region of a sample that was tested at 198 K. (d) The fracture surface shows ductile dimpled fracture and Cr-rich particles that act as void initiation sides. (Data points shown are mean±s.d.; see Supplementary Table 1 for exact values.) The scale bars in c and d, and the insets of d are 75, 5 and 2 μm, respectively.