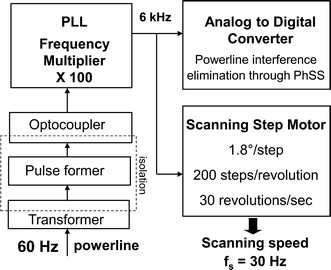

Fig. 6.

Deriving the A–D sampling rate and the step-motor pacing pulses from the power line frequency. In order to eliminate the power line interference along with the instrumental noise in the PhSS procedure, the motor was paced with a frequency which is a precise multiple of the 60 Hz power line frequency: 6000 steps/sec (100 × 60 Hz). The power line frequency was obtained by means of a transformer with 4 kV isolation. Multiplication of the power line frequency by a factor of 100 is achieved by means of a phase-locked-loop (PLL) circuit. Thus, the motor is spinning at a speed of 6000/200 = 30 rotations per second. At each new step, one sample from each channel is acquired, i.e. every new data sample corresponds to 1.8° of rotation (1 step). Each of the 200 samples during one scanning rotation corresponds to one particular angle of rotation, with the angles spaced evenly at 1.8° intervals. At the same time, there are exactly two complete power line cycles (60 Hz) in one scanning cycle (f s = 30 rps), which means that power line noise is eliminated by the 360° PhSS technique