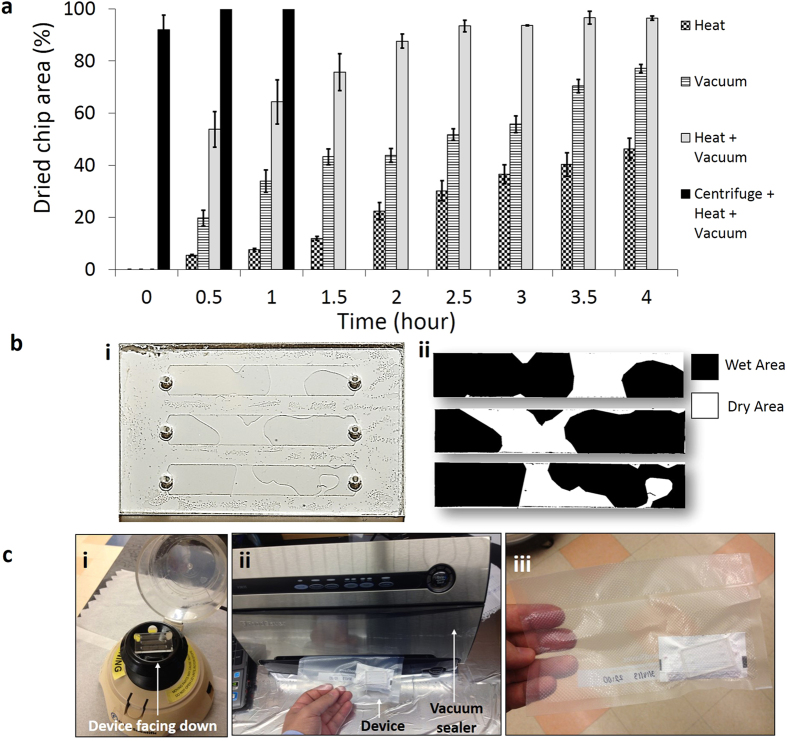

Figure 2. Microfluidic device drying, packing and storing methods.

(a) Devices were dried by four different methods, (i) heating (37 oC), (ii) vacuum (−761 mmHg), (iii) heating and vacuum (37 oC + −761 mmHg), and (iv) device centrifugation followed by heating and vacuum (37 oC + −761 mmHg), and dried device surface area was measured to quantify the drying efficiency. By using only heating or vacuum, devices were not dried fully even after 4 hours. Using heating plus vacuum we were able to dry 96% of the device surface area in 4 hours. The most time efficient method was device centrifugation followed by heating and vacuum. Using this method, devices were dried fully in an hour, n (no. of channels) =3. Error bars represent standard deviation. (b) (i) Whole device images were taken to quantify the drying area. Channel areas were cropped from image and drying area was calculated using ImageJ software. (ii) White and black areas represent the dried and wet regions of the device surface. (c) (i) Microfluidic devices were centrifuged to remove fluid from channels for fast drying. The device was placed on the centrifuge upside down (channel inlets facing downwards). To remove the remaining fluid, vacuum heating was applied. (ii) Devices were inserted into plastic bags with drying agent. Air inside the bag was pumped out using vacuum sealer and bag was sealed. (iii) Devices were ready for storing at room temperature.