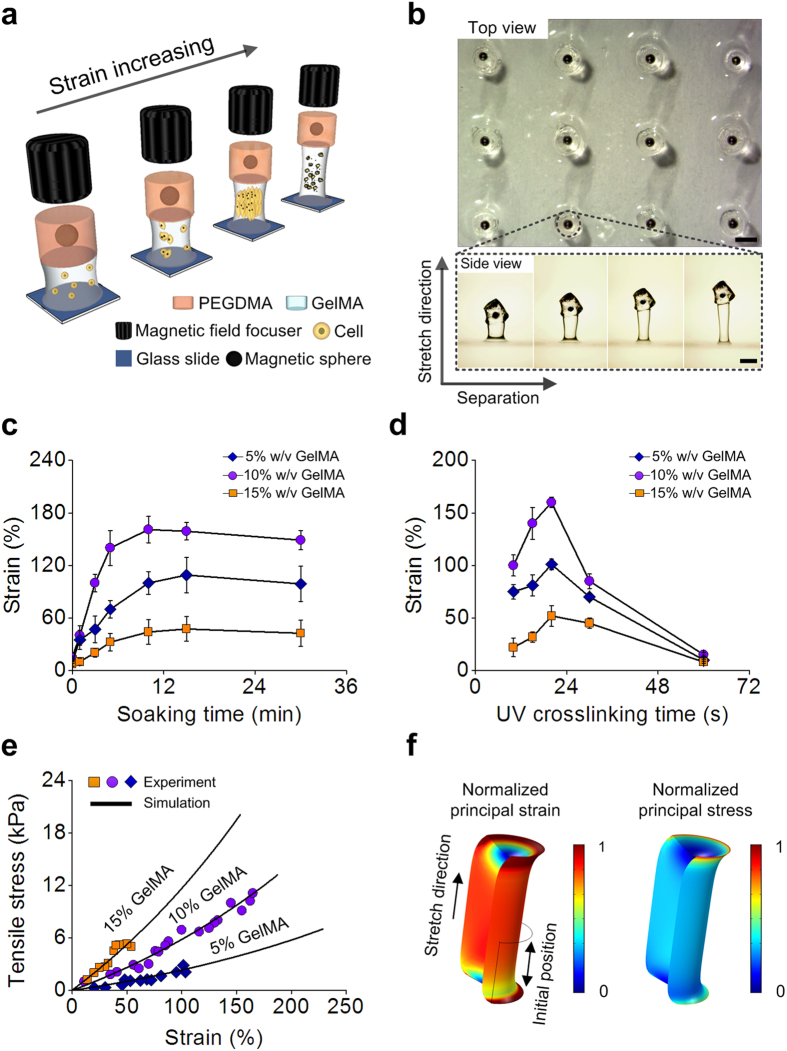

Figure 1. Characterization of microscale, magnetically-actuated synthetic tissues (μMASTs) and interdependence of strain and modulus on cell mechanosensitivity.

(a) Each μMAST contained a stiff, strong “magnetically-actuated” PEGDMA layer encapsulating an iron microsphere and a tunable-stiffness “synthetic tissue” GelMA layer encapsulating a population of cells. Strains were controlled magnetically using a magnetic field focusing device. (b) Top view (upper) of the fabricated μMASTs and side view (bottom) of one stretched μMAST under different straining. Synthetic tissue modulus: 6 kPa. (c) The failure strain that μMASTs could withstand prior to failure was maximized by modulating the “soaking time,” the interval between the pouring of the GelMA precursor/cell mixture into the rectangular cut-out in the mold “cover” and the initiation of UV photo-crosslinking. Here, UV photo-crosslinking time was fixed at 20 s and UV light power density was fixed at 2.9 mW cm−2. (d) UV photo-crosslinking time was modulated to maximize the failure strain. Here, soaking time was fixed at the optimum of 10 min, and UV light power density at 2.9 mW cm−2. (e) Representative stress-strain curves for synthetic tissue layers composed of different GelMA fraction were highly linear (symbols: experiment; lines: simulation). (f) Simulated strain (left) and stress (right) distributions in synthetic tissue layers under magnetic actuation showed highly uniform mechanical fields. Contours were normalized to the peak values. Scale bars: 800 μm.