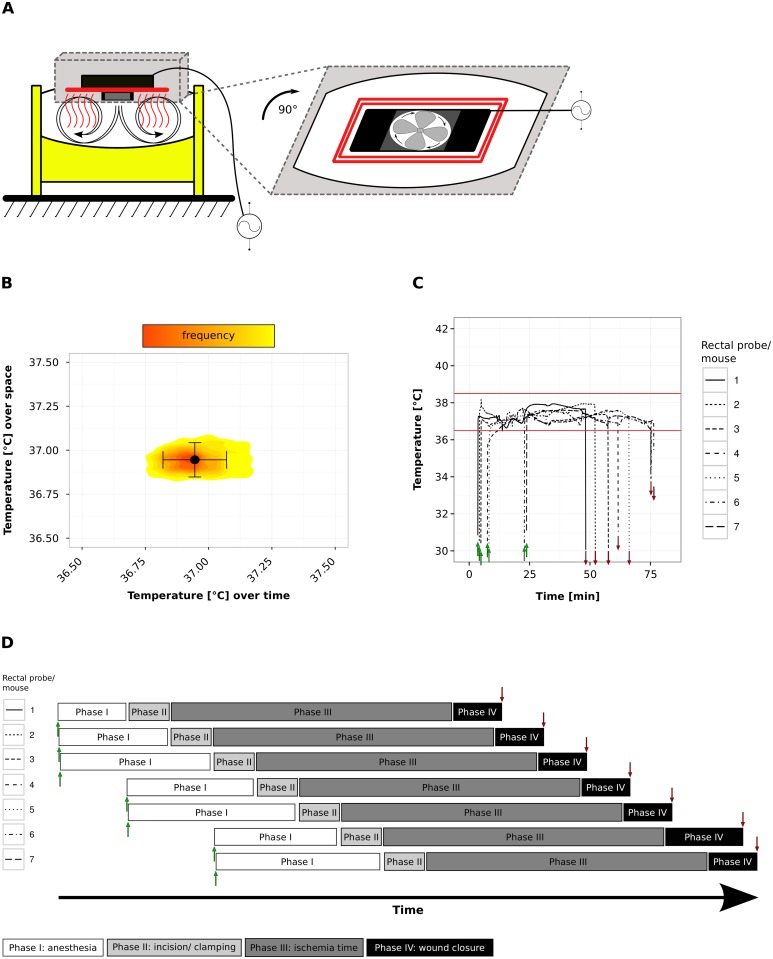

Fig 2. A ventilated heating chamber optimizes body temperature profiles and facilitates the surgery’s work-flow.

Schematic representation and temperature profile of the Octagon 20 Advance heating chamber (A and B): The Octagon 20 Advance (A) consists of a solid bottom (yellow) and a transparent upper part, which allows visual control during phase I and II of surgery. The electrical temperature control (black) and the heating element (red) are mounted on top of the chamber. The generated heat is distributed by a small ventilator. (B) The Octagon 20 Advance was set to 37.0°C and continuous temperature recording were conducted for 1 hour at 7 positions inside the breeding device. Temperatures recorded over time and space are plotted on the x- and y-axis, respectively. The black dot represents the overall mean value, the horizontal error bar the standard deviation over time and the vertical error bar the standard deviation over space. The heat-map in the background displays the distribution pattern of recorded temperature values in time and space. Setup C allows parallel surgery in up to 7 mice (C and D): Panel (C) displays a complete, representative set of ORTR generated raw data from 7 mice, where the green arrows indicate the insertion of the probe into the mouse (start of phase I) and where red arrows indicate the end of surgery (end of phase IV). Panel (D) illustrates the work-flow for the 7 parallel surgeries shown in (C). During phase III (ischemia time) of mouse no. 1 a single trained person is able to complete phase II for mice no. 2–7. Anesthetizing 2–3 mice simultaneously in phase I assured a sufficient scope of action for maintaining a constant work-flow, as sequence of surgery can be adapted to the individual body core temperature of every single mouse, which was standardized to be 37.5°C before staring phase II. Therefore, durations of phase I vary. In this specific example phase IV of mouse no. 6 was prolonged by issues during wound closure, which lead to the discontinuity of the steady sequence in surgery work-flow.