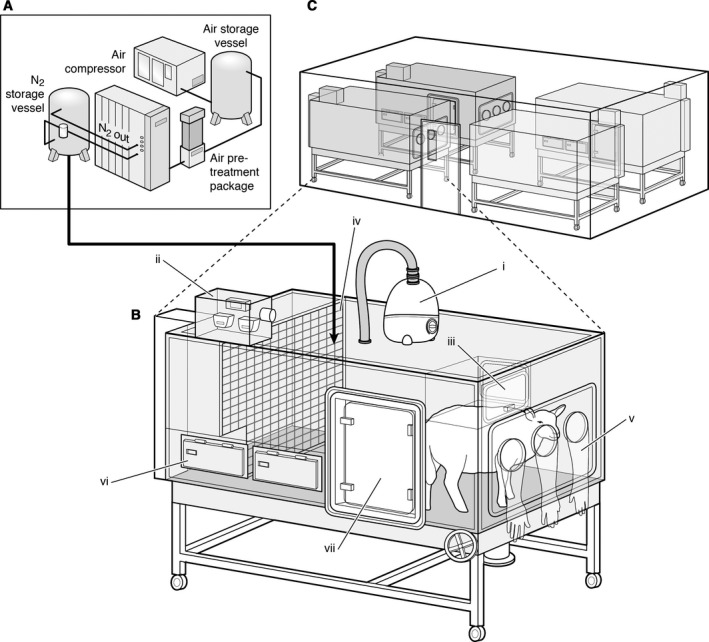

Figure 1.

Isobaric hypoxic chambers and nitrogen‐generating system. A specially designed nitrogen‐generating system (A) supplied variable amounts of compressed air and nitrogen to four bespoke isobaric hypoxic chambers housed in the hypoxic chamber laboratory (B and C). Each chamber was equipped with an electronic servo‐controlled humidity cool steam injection system to return the appropriate humidity to the inspirate (i). Ambient po 2, pco 2, humidity, and temperature within each chamber were monitored via sensors (ii). For experimental procedures, each chamber had a double transfer port (iii) to internalize material and a manually operated sliding panel (iv) to bring the ewe into a position where daily sampling of blood could be achieved through glove compartments (v). Each chamber incorporated a drinking bowl on continuous water supply and a rotating food compartment (vi) for determining food intake. A sealed transfer isolation cart could be attached to a side exit (vii) to couple chambers together for cleaning.