Abstract

Purpose:

Surface roughness promotes adhesion and colonization of denture plaque. Therefore, it is important to know the effects of polishing and finishing on the surface roughness of various acrylic resin materials.

Objectives:

To evaluate and compare the effects of different conventional lathe polishing techniques on heat cured acrylic resins in producing surface roughness.

Materials and Methods:

Three different commercially available heat-cured acrylic resin materials namely DPI, Meliodent and Trevalon Hi were selected. 30 Specimens of each acrylic material (30 x 3 = 90, 10 x 60 x 2mm) were prepared and divided into 5 groups, each group consisted of 6 Nos. of specimens per material(6x3=18) and were grouped as Group A(unfinished), Group B (finished), Group C (Polishing Paste), Group D (Polishing Cake) and Group E (Pumice and Gold rouge). The resulted surface roughness (μm) was measured using Perthometer and observed under Scanning Electron Microscope. The values obtained were subjected statistical analyses.

Results:

Among the materials tested, better results were obtained with Trevalon Hi followed by Meliodent and DPI. Among the polishing methods used, superior results were obtained with universal polishing paste followed by polishing cake; Pumice and Gold rouge. Although Pumice and Gold rouge values produced greater roughness value, they were well within the threshold value of 0.2 mm.

Key Words: Gold rouge, heat-cured acrylic resin, polishing cake, pumice, universal polishing paste

INTRODUCTION

Acrylic resins have been widely used in the dentistry since 1937, especially in the field of Prosthodontics to fabricate different types prostheses including complete and partial dentures, temporary fixed partial dentures, implant retained over dentures, and maxillofacial prostheses.[1,2,3,4,5,6] Popularity of acrylics accrues from the fact that the material exhibits favorable working characteristics, has acceptable physical, mechanical, and esthetic properties and is easy to fabricate with inexpensive equipment.[2,3] Among the properties required of materials used in denture construction, those relating to the surface, e.g. roughness, surface free energy, surface tension, wettability, hydrophobicity, hydrophilicity, electrostatic interactions, and microhardness are of clinical importance since they may affect plaque accumulation and staining.[7,8,9,10,11]

In particular, surface roughness provokes the adhesion and retention of Candida albicans, which is of specific importance in denture-induced stomatitis.[12,13,14,15,16,17]

The finishing and polishing of restorative dental materials are important steps in the fabrication of clinically successful restorations. This procedure is mandatory in order to enhance oral health, function, and esthetics. A well contoured and polished restoration promotes oral health by resisting the accumulation of food debris and pathogenic bacteria. This is accomplished through a reduction in total surface area and reduced roughness of the restoration surface.[6,7]

Surface roughness provokes the adhesion and retention of C. albicans which is of specific importance in denture-induced stomatitis. Therefore, a material should possess a smooth, polished surface, so that plaque accumulation is minimized or avoided and also to be acceptable.

In vivo studies by Bollen et al., and Quirynen and Bollen, and in vitro studies by O’Donnell et al., revealed that clinically acceptable roughness of hard surfaces in the oral environment after polishing should not exceed 0.2 µm (threshold value).[9,10,18]

Polishing can be performed through mechanical or chemical methods.[19] The fabrication of a removable prosthesis is mostly done by laboratory personnel by conventional lathe polishing techniques, who are less acquainted with clinical relevance of polishing of denture base resins and often create irregularities which predisposes to above mentioned.

Although, some studies have evaluated conventional lathe polishing, no study has examined effect of pumice, and gold rouge exclusively on heat-cured acrylic resins. Therefore, the present study was aimed to evaluate the efficacy of different polishing techniques and materials on the surface roughness of heat-cured acrylic resins using Perthometer and scanning electron microscope (SEM).

The objectives of the study were:

To evaluate the quality of three commercially available heat-cured acrylic resin denture base resins based on their surface roughness

To assess the efficacy of three conventional lathe polishing techniques on surface roughness using perthometer

To compare the surface roughness of three commercially available three heat-cured acrylic resins with three conventional lathe polishing techniques using SEM.

MATERIALS AND METHODS

Preparation of acrylic resin specimens

Three different commercially available heat-cured acrylic resin materials namely DPI, Meliodent, and Trevalon HI were selected. For preparation of specimens (10 mm × 60 mm × 2 mm) of acrylic resin material, six metal sample analogues of same dimensions were used in order to obtain six specimens of equal dimensions treated under the same conditions. Thirty specimens (30 × 3 = 90) of each acrylic resin product were prepared according to the manufacturer's instructions with respect to powder-liquid ratio, mixing, and packing. A standardized polymerization procedure was followed; with one cycle at 70°C for 8 h followed by a 1 h cycle at 100c under flask clamp pressure. The flasks were then left to cool at room temperature. By the above-mentioned manner, 30 samples per acrylic resin product were obtained that is, 30 × 3 = 90 samples.

Grouping of samples

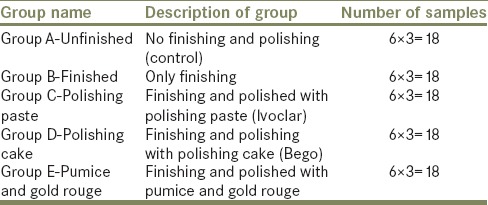

Thirty samples fabricated with each material were divided into five groups; each group consisting six number of samples of each material (5 × 6 = 30) [Table 1].

Table 1.

Groups depicting with methodology and number of samples

The materials and instruments used in finishing and polishing were:

Finishing procedure

Materials used

Tungsten carbide bars (Brasseler)

Sand paper (No. 80, 100 and 120)

Rubber wheels (fine and very fine).

Instruments used

Sand paper mandrel

Laboratory micromotor with control box and straight hand piece (Ultimate 400, NSK Company)

Timer.

Polishing procedure

Materials used

Universal polishing paste (Ivoclar)

Polishing cake (Bego)

Pumice (Micro white, Asian chemicals)

Gold Rouge (Bego).

Instruments used

Felt cone

Soft cloth wheels (which are prepared)

Polishing unit (Kavo)

Timer.

Group A (Unfinished)

First six samples per each material which did not receive any finishing and polishing were grouped and named as Group A, which formed the control group (6 × 3 = 18).

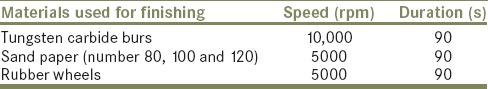

The remaining 24 samples fabricated per material were finished using of lab micromotor with control box and straight hand piece (Ultimate 400, NSK Company) using Tungsten Carbide burs, sandpaper held in sand paper mandrel (No. 80, 100 and 120), and rubber wheels (fine and very fine). A standardized finishing protocol with Tungsten carbide burs at a speed of 10,000 rpm for 90 s, followed by sandpaper at a speed of 5000 rpm for 90 s, followed by rubber wheels at a speed of 5000 rpm for 90 s was followed [Table 2].

Table 2.

Finishing protocol

Group B (Finished)

Six specimens of each material which received only finishing were grouped and named as Group B (6 × 3 = 18).

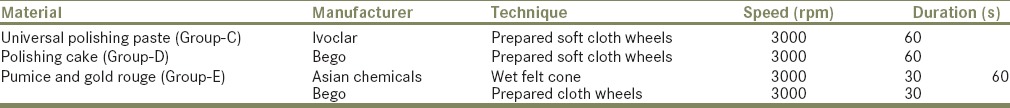

The remaining 18 samples per material which had undergone finishing procedure were further divided into three groups [Table 3].[6,7,18,19] Each of this group was subjected to one polishing technique. The polishing technique requires soft cloth wheels which were prepared as follows:

Table 3.

Polishing protocol

A new cloth wheel was placed on a sturdy bench lathe and lathe was turned on high speed

A new cloth wheel was run against the back side of knife blade

After several turns of cloth wheel against the knife blade, strings appeared at the periphery of the cloth wheel

Strings appeared were cut with scissors and it was passed over a small flame

The cloth wheel was broken and ready for use when strings no longer appeared.

Group C

Set of six samples per material which were polished with universal polishing paste which was composed of aluminum oxide, (Ivoclar) on soft cloth wheel for 60 s using polishing unit (Kavo) at 3000 rpm (6 × 3 = 18).

Group D

Set of six samples per material which were polished with polishing cake which was composed of aluminum oxide, (Bego) on soft cloth wheels for 60 s using polishing unit (Kavo) at 3000 rpm (6 × 3 = 18).

Group E

Set of six samples per material which were polished with pumice and gold rouge (6 × 3 = 18). The finished samples were first subjected to polishing on a wet felt cone with pumice to achieve initial high shine and later subjected to polishing on the surface of soft cloth wheel with gold rouge to achieve final high shine. Above procedure was performed using the polishing unit (Kavo) for 60 s (i.e., 30 s with pumice and wet felt cone, 30 s with soft cloth wheel and gold rouge). Gold rouge was used along with pumice for polishing of the acrylic specimen in accordance with the finishing protocol given by Rudd et al.[20]

All the polishing protocols in Groups C, D, and E were done on the handheld rotary system.

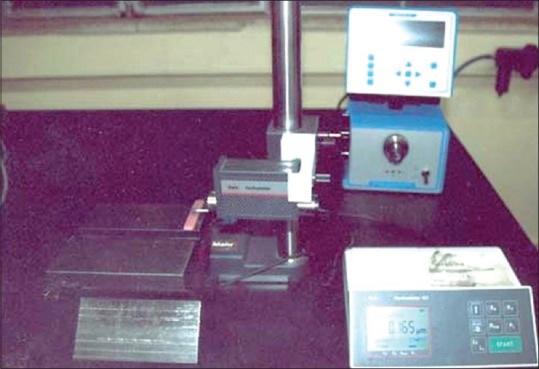

Surface roughness of all specimens was measured using Perthometer and compared with SEM observations.

All the above-mentioned groups of samples were evaluated using Perthometer (Mahr, Manufacturer). Each of the samples per material under one group were placed on the platform provided and were positioned in such a way that the probe of the Perthometer is just in contact with the surface of the sample. The probe was allowed to pass over the entire surface of the sample and measurement was recorded. The average measurement was taken as value of surface roughness for that particular sample [Figure 1].

Figure 1.

Measuring surface roughness of different heat-cured acrylic resin material using Perthometer

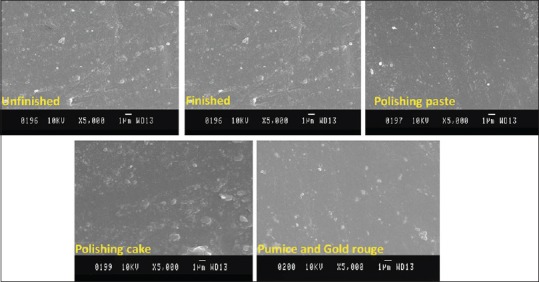

All the six samples per material of five groups were evaluated for surface roughness in above-mentioned manner and average measurements were recorded in microns (µm). Surface roughness evaluation of samples was also done using SEM (JEOL, JSM-840A Scanning microscope) for which; 5 mm × 5 mm piece of acrylic resin was cut out of each sample and prepared. All samples were cleaned with 70% alcohol in an ultrasonic cleaner and sputter coated with Gold in vacuum. Acrylic surfaces were examined under a SEM (JEOL, JSM-840A Scanning microscope) at 10 KV and photomicrographs at a magnification of ×5000 at working distance of 13 mm were made.

Statistical analyses

Statistical analyses were done using SPSS software (version 20, SPSS Inc., IBM Corp. Chicago, IL, USA). Mean roughness were compared between various groups using two-way ANOVA. Post hoc analyses were done using Scheffe's test. For all comparisons, a P < 0.05 was considered as significant.

RESULTS

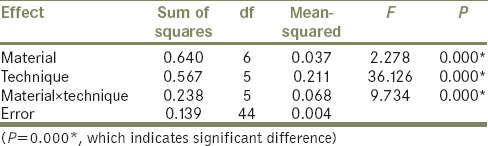

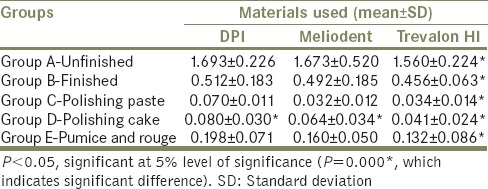

Tables 4 and 5 show comparison between mean roughness values of various materials and methods used for polishing. Mean surface roughness values (μm) measured between the groups were found statistically significant in relation to the materials used namely DPI, Meliodent, and Trevalon HI material (P < 0.05) that is, between unfinished to finished, finished to polished groups of samples, and unfinished to polished groups of samples (P < 0.05). Mean surface roughness values among the materials used in Group C - Polishing Paste (DPI 0.070, Meliodent 0.032, and Trevalon HI 0.034) were found to be statistically significant (P < 0.05).

Table 4.

Two-way analysis of variance

Table 5.

Comparison of mean surface roughness (μm) groups in each material used and materials in each group

Further analysis revealed that there was statistically no significant difference in mean surface roughness between Meliodent and Trevalon HI (P > 0.05), whereas DPI was statistically significant from Meliodent, Trevalon HI materials (P < 0.05) Mean surface roughness values among the materials used in Group D - Polishing Cake (DPI 0.080, Meliodent 0.064, and Trevalon HI 0.041) and Group E – Pumice and Gold rouge (DPI 0.198, Meliodent 0.160, and Trevalon HI 0.132) were found to be statistically insignificant (P > 0.05).

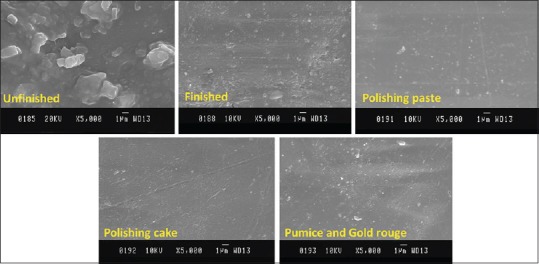

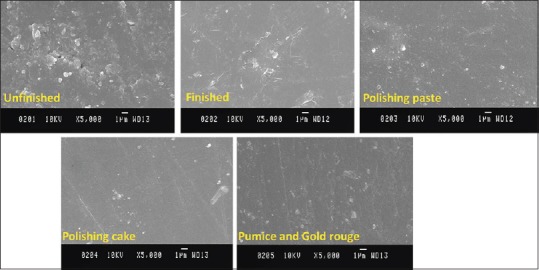

Figures 2–4 show SEM photomicrographs of the samples of three materials namely DPI, Meliodent, and Trevalon HI, which were unfinished, finished, polished with polishing paste, polishing cake; pumice and gold rouge, respectively.

Figure 2.

Scanning electron microscope images of DPI material in all the groups (×5000)

Figure 4.

Scanning electron microscope images of Trevalon HI material in all the groups (×5000)

Figure 3.

Scanning electron microscope images of Meliodent material in all the groups (×5000)

DISCUSSION

Placement of a removable prosthesis in the oral cavity produces profound changes of the oral environment that may have an adverse effect on the integrity of the oral tissues. Mucosal reactions could result from a mechanical irritation by the dentures, an accumulation of microbial plaque on the dentures or occasionally, a toxic or allergic reaction to constituents of the denture material.[1,5,8] The former two factors are attributed to surface irregularities or micro porosities of denture base materials. This greatly promotes plaque accumulation by enhancing the surface area exposed to microbial colorization and also aids in the attachment of plaque.[8,9,10,11]

The present study was undertaken to know the efficacy of various conventional lathe polishing systems on three commercially available heat-cure acrylic resin materials which are commonly used for the fabrication of removable prostheses as well as various appliances. In the present study, heat-cure acrylic resin material was preferred as the material of choice. Even though, cold cure acrylic resin material can be used as denture base materials, it differed from heat-cure acrylic resin in its properties like more residual monomer content, incomplete polymerization leading to inferior mechanical properties; and compromised biocompatibility.[2,3,4,5,6,7] Earlier studies also have shown that when polishing (conventional/chairside) was performed on auto polymerized resin, it remained porous which favored plaque formation and bacterial contamination.[6,7,18]

In general, two different modalities of polishing systems are used, namely conventional lathe polishing and chairside polishing. Chairside polishing systems are employed by the dentists during postinsertion procedures to correct or re-modify the surfaces of complete or partial dentures.[6,7,18,19] Although, chairside polishing is equally effective in reducing surface roughness, it is inferior to conventional lathe polishing as demonstrated in the studies of Kuhar and Funduk, O’Donell et al., and Sofou et al.[6,18,22]

Another advantage with lathe polishing techniques is that the dental lathe and the polishing materials are relatively economical when compared to chairside polishing technique for which silicone rubber wheels have to be used.[20]

The traditional technique for finishing and polishing acrylic removable appliances is to utilize pumice mixed with water to form a mud-like material which is scooped by hand and placed at random on and around the appliance. Once applied, the appliance is then positioned against a rotating wheel mounted on a lathe to gradually eliminate shaping and finishing scratches and marks. This procedure is repeated numerous times until the surface of the acrylic appliance is rendered smooth. The operation is rather a “wet mess” the resultant wet mass of “sand” contained in a holding pan, was often re-used from one appliance to another – including dentures that might have been repaired after having been worn in patients’ mouths for some time. Cross-contamination was a constant possibility. Recent steps have been taken to eradicate or lessen this possibility with the use of pumice substitutes; however, products of this type still offer the messiness of being mixed with water, the light-powdery nature of the particles, and other possible health issues.

Hence, the laboratory lathe polishing systems were chosen for the study along with various brands of heat-cure acrylic resin viz., Trevalon HI, Meliodent, and DPI. Results obtained from this study revealed that, smother surfaces were achieved with Trevalon HI followed by Meliodent and DPI. This result could be attributed to variation in the chemical composition of the respective resin material. Three different polishing materials were selected for the study namely, pumice and gold rouge, polishing paste, and polishing cake.

The factors involved in the outcome of polishing with loose abrasives such as polishing paste are: (i) Mean particle size of abrasive particles, (ii) structure and firmness of the application device used to apply the loose abrasive, (iii) composition of loose abrasive paste, (iv) application technique and incremental use of water in final polishing step to increase lubrication of particles at the surface of acrylic resin material to enhance polishing action.[21]

Results obtained with three polishing techniques indicated that polishing paste and polishing cake yielded better results over pumice and gold rouge. Although composition being same for both polishing paste and polishing cake (i.e., aluminum oxide) superior results achieved with polishing paste might be due to differences in the size of abrasive particles and dispersion medium.[18,22] Moreover, the increase in lubrication of particles at the surface of the acrylic resin may be a factor for better results using abrasive paste.[21] Pumice and gold rouge can be used for conventional polishing system, its efficacy was not evaluated in earlier studies.

In a study conducted by Al-kheraif on evaluation of surface roughness of heat-cured and light cured acrylic denture base resins using mechanical and chemical polishing techniques, mechanical polishing techniques produced better results than chemical polishing techniques. Moreover, on a comparison of polishing materials Resilit high-luster polishing liquid produced better results over the universal polishing paste.[19] In the present study, we have compared the surface roughness of three different heat-cured acrylic resin denture base material using different polishing materials and found better results with universal polishing paste.

In a similar study conducted by Sofou et al. on evaluation of surface roughness of three commercially available heat-cured acrylic resin materials using polishing soap, paste and UV-light-activated resin sealant, better results were obtained using universal polishing paste.[22] Similarly, in our study, polishing paste produced better results than polishing cake and pumice with gold rouge.

Gross irregularities on untreated specimens of the acrylic resin materials were observed from SEM micrographs, but it was obvious that the finishing removed gross irregularities to a great extent. SEM observation also revealed the fact that, application of polishing paste gave smoother surface on all three materials followed by polishing cake. However, pumice and gold rouge also produced a smoother surface.

A standardized in vitro protocol was followed for the fabrication of acrylic samples also. The use of standardized metal sample analogues eliminated waxing and dewaxing procedures thus variability in the fabrication of acrylic samples was minimized. The metal sample analogs have comparatively smoother surface, and thus the unfinished samples in this study exhibited less roughness values as compared to other studies. The main limitation of the study was that the clinical conditions were not simulated. It is always emphasized that waxing, finishing, and polishing of trial denture bases or any prosthesis plays an important role in the final outcome of the prosthesis with respect to surface roughness.

Even though the speed of the lathe for polishing and pressure of rotary polishing were standardized, the same ideal conditions in the dental laboratories on a routine basis cannot be anticipated. The polishing efficiency always varies with the condition of the dental lathe and dexterity of the operator.

Another limitation with this study was that the surfaces of acrylic samples were flat when compared to any removable prosthesis which has curved surfaces. In fact Kuhar and Funduk, Zissis et al., and Sofou et al. recommended the use of chairside polishing technique in combination with conventional polishing techniques in areas which cannot be reached using a dental lathe.[6,7,22]

In spite of limitations mentioned earlier, if the protocol of this study is followed, the surface roughness would be well within the threshold limit. The obtained SEM images do confirm it.

CONCLUSION

Among the materials tested, smoother surfaces were obtained with Trevalon HI followed by Meliodent and DPI. Among the polishing materials tested, polishing paste produced better results followed by polishing cake; pumice and gold rouge. Even though, pumice and gold rouge produced increased surface roughness, the values obtained were below or equal to threshold value (0.2 µm). SEM photomicrograph observations revealed that finishing and polishing reduced the surface roughness which were similar to the findings obtained by Perthometer.

Financial support and sponsorship

Nil.

Conflicts of interest

There are no conflicts of interest.

REFERENCES

- 1.Wong DM, Cheng LY, Chow TW, Clark RK. Effect of processing method on the dimensional accuracy and water sorption of acrylic resin dentures. J Prosthet Dent. 1999;81:300–4. doi: 10.1016/s0022-3913(99)70273-8. [DOI] [PubMed] [Google Scholar]

- 2.Craig RG, O’Brien WJ, Powers JM, editors. Text book on Dental Materials. 6th ed. St. Louis: Mosby Publisher; 1996. Plastics in prosthethics; pp. 242–65. [Google Scholar]

- 3.Phoenix RD. Denture base resins. In: Anusavice KJ, editor. Text Book on PHILLIPS Science of Dental Materials. 11th ed. St. Louis: Elsevier Publisher; 2003. pp. 721–56. [Google Scholar]

- 4.O’Brien WJ, editor. Text Book on Dental Materials and their Selection. 3rd ed. Kimberly Drive, Carol Stream: Quintessence Publisher; 2002. Polymers and polymerization; pp. 74–89. [Google Scholar]

- 5.Diwan RR. Materials prescribed in the management of edentulous patients. In: Zarb GA, Bolender CL, editors. Text Book on Prosthodontic Treatment for Edentulous Patients. 12th ed. St Louis: Elsevier Publisher; 2004. pp. 190–207. [Google Scholar]

- 6.Kuhar M, Funduk N. Effects of polishing techniques on the surface roughness of acrylic denture base resins. J Prosthet Dent. 2005;93:76–85. doi: 10.1016/j.prosdent.2004.10.002. [DOI] [PubMed] [Google Scholar]

- 7.Zissis AJ, Polyzois GL, Yannikakis SA, Harrison A. Roughness of denture materials: A comparative study. Int J Prosthodont. 2000;13:136–40. [PubMed] [Google Scholar]

- 8.Budtz Jorgensen E. Sequelae caused by wearing complete dentures. In: Zarb GA, Bolender CL, editors. Text Book on Prosthodontic Treatment for Edentulous Patients. 12th ed. St Louis: Elsevier Publisher; 2004. pp. 34–50. [Google Scholar]

- 9.Bollen CM, Lambrechts P, Quirynen M. Comparison of surface roughness of oral hard materials to the threshold surface roughness for bacterial plaque retention: A review of the literature. Dent Mater. 1997;13:258–69. doi: 10.1016/s0109-5641(97)80038-3. [DOI] [PubMed] [Google Scholar]

- 10.Quirynen M, Bollen CM. The influence of surface roughness and surface-free energy on supra- and subgingival plaque formation in man. A review of the literature. J Clin Periodontol. 1995;22:1–14. doi: 10.1111/j.1600-051x.1995.tb01765.x. [DOI] [PubMed] [Google Scholar]

- 11.Quirynen M, Marechal M, Busscher HJ, Weerkamp AH, Darius PL, van Steenberghe D. The influence of surface free energy and surface roughness on early plaque formation. An in vivo study in man. J Clin Periodontol. 1990;17:138–44. doi: 10.1111/j.1600-051x.1990.tb01077.x. [DOI] [PubMed] [Google Scholar]

- 12.Monsenego P. Presence of microorganisms on the fitting denture complete surface: Study ’in vivo’. J Oral Rehabil. 2000;27:708–13. doi: 10.1046/j.1365-2842.2000.00564.x. [DOI] [PubMed] [Google Scholar]

- 13.Davenport JC. The denture surface. Br Dent J. 1972;133:101–5. doi: 10.1038/sj.bdj.4802881. [DOI] [PubMed] [Google Scholar]

- 14.Spiecowiciz E, Santarpia RP, Pollock JJ, Renner RP. In vitro growth of Candida albicans on differently prepared acrylic resin surfaces. Dent Mater Sci. 1989;13:161–4. [Google Scholar]

- 15.Waltimo T, Vallittu P, Haapasalo M. Adherence of Candida species to newly polymerized and water-stored denture base polymers. Int J Prosthodont. 2001;14:457–60. [PubMed] [Google Scholar]

- 16.Taylor R, Maryan C, Verran J. Retention of oral microorganisms on cobalt-chromium alloy and dental acrylic resin with different surface finishes. J Prosthet Dent. 1998;80:592–7. doi: 10.1016/s0022-3913(98)70037-x. [DOI] [PubMed] [Google Scholar]

- 17.Waltimo T, Tanner J, Vallittu P, Haapasalo M. Adherence of Candida albicans to the surface of polymethylmethacrylate – E glass fiber composite used in dentures. Int J Prosthodont. 1999;12:83–6. [PubMed] [Google Scholar]

- 18.O’Donnell EF, Radford DR, Sinclair GF, Clark RK. Chairside polishing of heat-cured acrylic resin: An SEM and EDA study. Int J Prosthodont. 2003;16:233–8. [PubMed] [Google Scholar]

- 19.Al-Kheraif AA. The effect of mechanical and chemical polishing techniques on the surface roughness of heat-polymerized and visible light-polymerized acrylic denture base resins. Saudi Dent J. 2014;26:56–62. doi: 10.1016/j.sdentj.2013.12.007. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 20.Rudd KD, Morrow RM, Espinoza AV, Leachman JS. 2nd ed. St Louis: The CV Mosby Company; 1986. Finishing and polishing. Dental Laboratory Procedures for Complete Dentures; pp. 334–5. [Google Scholar]

- 21.O’Brien WJ, editor. Text Book on Dental Materials and their Selection. 3rd ed. Carol Stream: Quintessence Publisher; 2002. Abrasion, polishing and bleaching; pp. 156–64. [Google Scholar]

- 22.Sofou A, Emmanouil J, Peutzfeldt A, Owall B. The effect of different polishing techniques on the surface roughness of acrylic resin materials. Eur J Prosthodont Restor Dent. 2001;9:117–22. [PubMed] [Google Scholar]