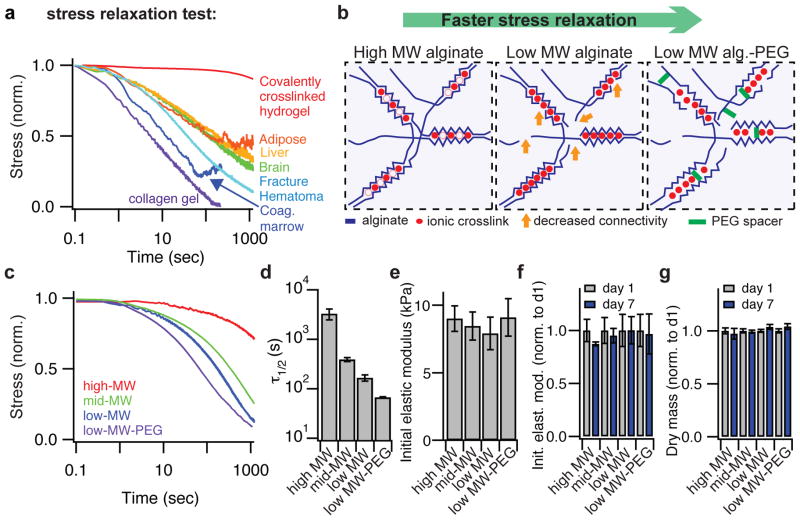

Figure 1. Modulating the nanoscale architecture of alginate hydrogels to modulate stress relaxation properties independent of initial elastic modulus and matrix degradation to capture the viscoelastic behaviors of living tissues.

a, Living tissues are viscoelastic and exhibit stress relaxation. Stress relaxation tests of a crosslinked hydrogel (polyacrylamide), a collagen gel, an initial fracture hematoma (human), and various tissues (rat) at a strain of 15%. Stress is normalized by the initial stress. b, Schematic depicting how lowering the molecular weight (MW) of alginate polymers (blue) crosslinked by calcium (red) decreases entanglement and connectivity (orange arrows) of the network, and coupling of low-MW PEG spacers provides a steric spacing of crosslinking zones in the alginate. Both approaches are predicted to increase the rate of stress relaxation. c, Stress relaxation tests on gels composed of alginates with different molecular weights, or low molecular weight alginate coupled to a PEG spacer (15% compressional strain). d, Quantification of timescale at which the stress is relaxed to half its original value, τ1/2, from stress relaxation tests in c. Timescale of stress relaxation decreases significantly with alteration in architecture (Spearman’s rank correlation coefficient, p < 0.0001). e, Initial modulus measurements of gels in c. Differences between elastic moduli are not significant, and elastic moduli show no statistical trend with altered architecture. f, Initial elastic modulus of alginate hydrogels after 1 day or 7 days in culture, normalized by the value at day 1. g, Measured dry mass of alginate hydrogels after 1 day or 7 days in culture normalized by the value at day 1. All data are shown as mean +/− s.d.