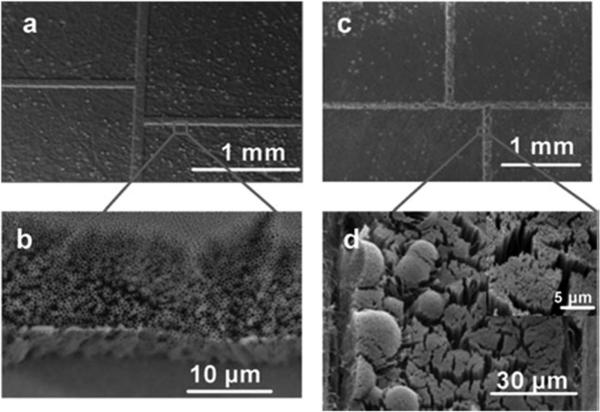

Fig. 15.

SEM images of the AAO/Al template prepared by UV lithography (a), (c) and the corresponding microstructures containing nanopillars (b), (d). In (a) and (c) are shown ‘double T’ fluidic channels (50 μm wide, 100 μm deep); (b) side view of the AAO micromold populated with nanopores (150 nm in diameter and 100 μm in height); (d) a top view of the molded microchannel filled with nanopillars (150 nm diameter and 100 μm height). The fluidic structures were made via high precision micromilling of an AAO template, followed by pre-polymer injection over the AAO template, polymerization, Al removal, thermal fusion bonding of a polymer cover plate and removal of the AAO template. Reproduced with permission from Chen et al. (2006).255