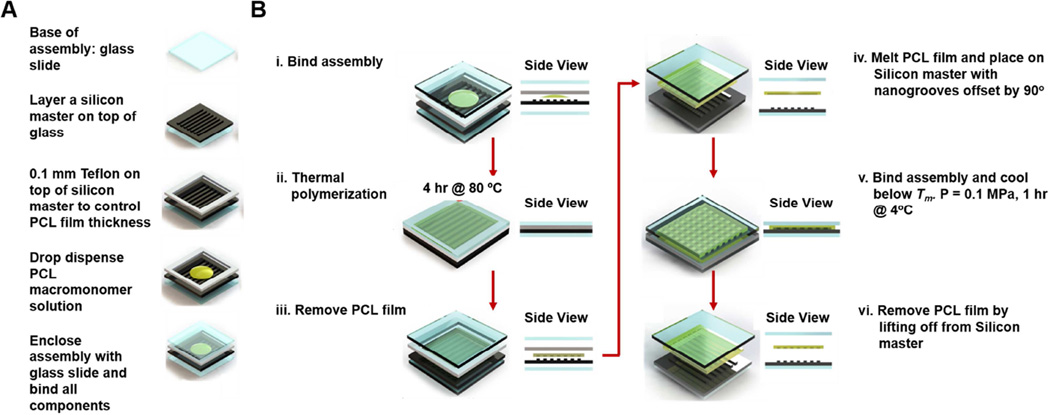

Figure 1. Fabrication of PCL-based shape memory nanogrooves with a temporary and permanent state.

(A) During prefabrication assembly, a Teflon spacer is used to control PCL film thickness, and PCL macromonomer solution is sandwiched between a silicon master and glass slides. The assembly is bound (Bi.) and then thermal polymerization takes place at 80°C for 4 hours (Bii.). Then, the PCL film is lifted off with a nanogrooved permanent state (Biii.). Next, a temporary pattern with anisotropic nanogrooves oriented 90 degrees from the permanent state is fabricated. (Biv.) The permanent pattern is melted at 80°C for 2 minutes and then placed on the silicon master with a 90 degree groove offset. It is then bound in between glass slides with a pressure of 0.1 MPa. (Bv.) The assembly is cooled for 1 hour at 4°C, and then the PCL film is lifted off (Bvi.), achieving a PCL-based SMP with a temporary and permanent anisotropic nanogrooved state that are orthogonally offset.