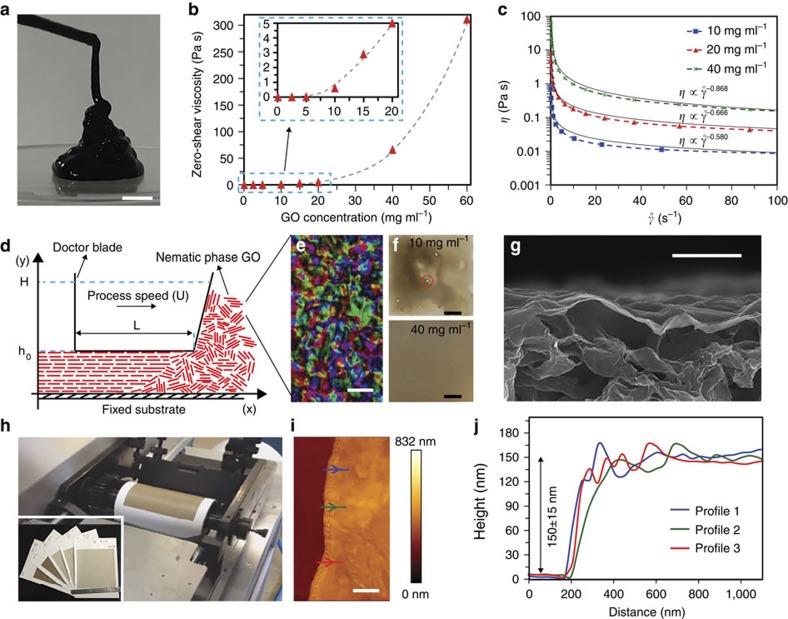

Figure 2. Fabrication of shear-aligned membrane from nematic GO.

(a) Viscoelastic property of GO (∼40 mg ml−1). Scale bar, 1 cm. (b) Zero-shear viscosity of the dispersions increases with increasing GO concentration. Dashed line is a polynomial fit. (c) Rheology data for three different concentration showing shear-thinning behavior. Solid curves are the fit of the experimental data with a power law model. (d) Schematic of shear-alignment processing of a nematic GO to a film; L is the width of blade, h0 is the height of the channel, H is the height of the fluid in front of the blade and U is the processing speed. (e) Polarized light images of fully nematic GO at 40 mg ml−1 (scale bar, 1 μm). (f) The red circle in the photograph identfies dewetting spots in the SAMs, which is eliminated when processed from liquid crystalline GO (scale bars, 1 cm). (g) An SEM image demonstrates continuity and conformity of SAM over a porous Nylon substrate (scale bar, 1 μm). (h) Photograph of the gravure printing machine and (inset) images of 13 × 14 cm2 GO membranes with different thicknesses. (i,j) AFM height map and corresponding height profiles of our membrane (scale bar, 1 μm).