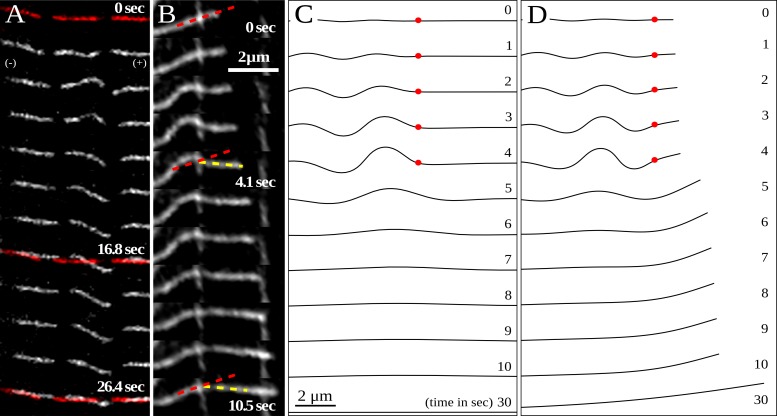

Fig 3. Rotation of the microtubule tip due to local bend formation.

(A) Images show that the microtubule shape on either side of the bend remained almost the same, and the initial shape was ultimately restored after the bend relaxed (initial and final shapes marked in red). (B) An example of a microtubule that changes direction of polymerization due to a local bend near the tip. Initially the filament is aligned at an angle of roughly 30 degrees to the horizontal (marked by red dash), but as soon as the bend starts to form, the tip starts to rotate toward the horizontal direction. The plus end continues to grow as the bend develops over the course of about three seconds. The bend relaxes after about 10 seconds, but the tip keeps growing in the newly acquired direction (marked in yellow). (C) Simulation of local bend formation when the pinning point is far from the tip (as in the experiment shown in panel A). The red dot indicates the pinning site which is initially at a distance of 8 μm from the tip. A bend forms within the first 5 seconds, after which the pinning point is released. The segment on the plus side of the pinning point does not rotate because of the large lateral friction along its length. As a result, the direction of microtubule growth remains unchanged. (D) Local bend formation when the pinning point is close (0.5 μm) to the tip (as in the experiment shown in panel B). The short microtubule segment to the plus side of the pinning point changes direction during bend formation, but microtubule growth during the pinning event increases the lateral friction and prevents the tip relaxing back to its original direction after the pinning point is released. There is a net change in the tip direction even after 30 seconds.