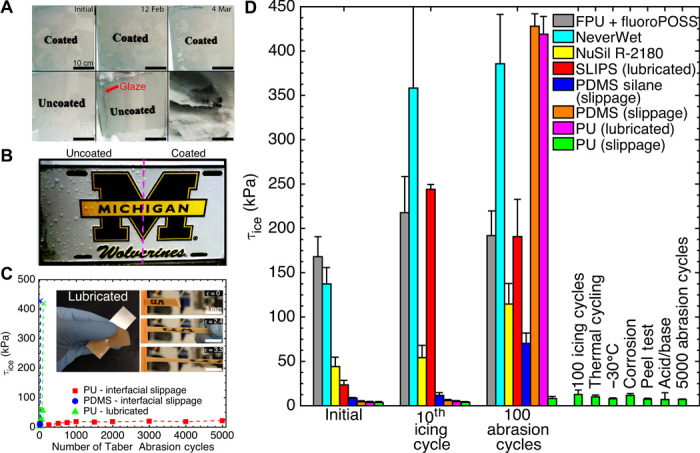

Fig. 5. Durability of the different icephobic coatings developed in this work.

(A) Outdoor testing of a PDMS-based coating (coating NN; see Table 1) for 4 months during winter 2014. On 12 Febuary, the uncoated panel was covered with a ~7-mm layer of glaze, the type of ice with the strongest adhesion (1). No ice had accreted on the coated panel. On 4 March, snow followed a night of freezing rain, which completely covered the uncoated panel. The coated panel only had a small amount of accreted ice remaining. (B) Half-coated license plate during outdoor winter 2013 testing, with ice only accreted on the uncoated side. (C) Mechanical abrasion of three different icephobic coatings. The PDMS (coating NN) and lubricated PU (coating CC) were easily damaged and delaminated within 20 abrasion cycles, whereas the PU with interfacial slippage (coating CB) survives over 5000 cycles while maintaining low ice adhesion. (D) Comparison of coatings in this work with other state-of-the-art icephobic surfaces. Also, additional durability characterizations are presented for the PU coating with interfacial slippage. For details on each coating and test configuration, see Materials and Methods.