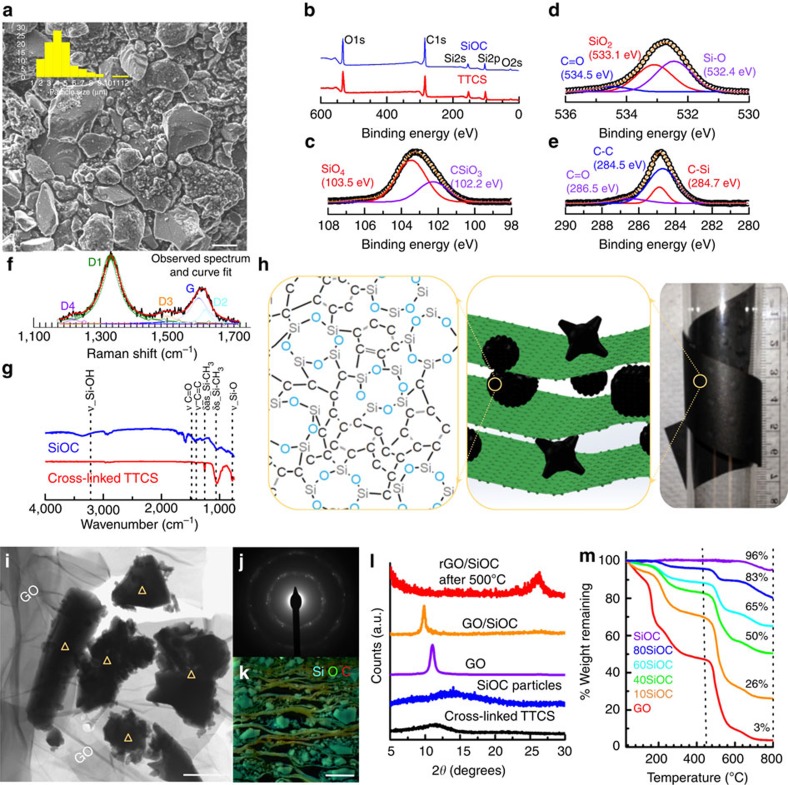

Figure 1. Characterization of SiOC ceramic and SiOC/graphene composite papers.

(a) SEM image of SiOC particles after pyrolysis of the polymeric TTCS particles. Sharp glass-like particles decorated with sub-micron size particles were observed. Scale bar is 5 μm. (b) XPS survey scans for cross-linked TTCS and pyrolyzed SiOC. High resolution XPS spectrum of pyrolyzed SiOC particles in the (c) Si 2p region, (d) O 1s region and (e) C 1s region were consistent with the polymer-derived SiOC nanodomain model. Deconvoluted peaks indicate the various bonds between Si, C and O atoms that are distinct to pyrolyzed SiOC. (f) Raman spectrum of SiOC showed peaks that are characteristic of graphite-like carbon (D1-peak: 1,350 cm−1 and G-peak: 1,590 cm−1). (g) Fourier Transform Infrared Spectroscopy spectra of SiOC and cross-linked TTCS (ν: stretching vibration mode and δ: bending vibration mode). (h) Digital camera picture and schematic illustration of proposed hybrid structure of the freestanding paper along with the atomic structure of pyrolyzed SiOC particle. (i) TEM image of SiOC/GO composite material. Large GO flakes covering SiOC particles (Δ) were observed. Scale bar is 500 nm. (j) Corresponding TEM selected area electron diffraction pattern showed multiple spot pattern due to polycrystallinity of restacked GO sheets with faint ring pattern attributed to amorphous SiOC material. (k) FIB cross-sectional EDX elemental map of 60SiOC paper in which Si, C and O are indicated by blue, red and green, respectively. The scale bar is 5 μm. Additional TEM and SEM images are presented in Supplementary Figs. 6–8. (l) XRD of cross-linked TTCS, SiOC particles, GO and composite papers before and after thermal reduction (annealing). Complete reduction of GO to rGO is illustrated in the plot. (m) TGA curves of GO paper and unannealed composite paper measured from 30 to 800 °C (10 °C min−1) in flowing air (20 ml min−1). The weight percentage of SiOC in the unannealed composite is as indicated in the figure.