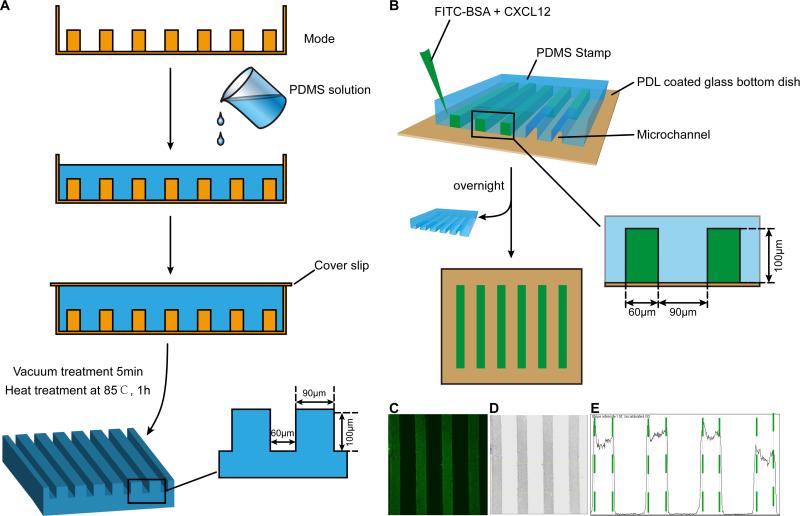

Figure 1. Schematic illustration of stripe assay.

The PDMS stamp was fabricated using mold etched by soft lithography with PDMS. A: To fabricate the PDMS stamp, the mold was first exposed to chlorotrimethylsilane vapor for 3 minutes in order to promote elastomer release after the baking steps. A mixture of PDMS was degassed for 10 minutes and then poured onto the mold. After degassing (5 minutes), the mold was baked for 60 min at 85 °C. Subsequently, the PDMS flow layer structure was then peeled from the mold. B: Schematic illustration of the procedures for fabricating stripe. C: Fluorescent image of FITC-conjugated BSA diluted in PBS (0.1 mg/ml) and infused into micro channels sealed by a PDMS stamp on a glass slide to create BSA density. D: After inverted and discolored, the picture in B turned to C. E: Pixel intensity of the channel was quantified using Image J software.