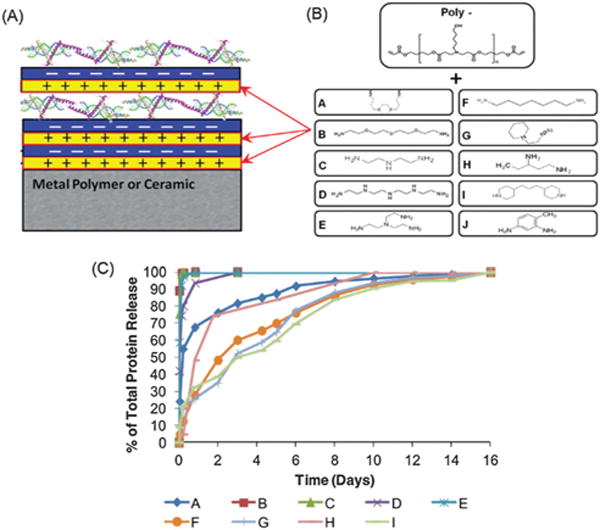

Fig. 4.

(A) Schematic of LbL assembly; (B) chemical structures of the end group of the cationic polymer used in constructing the LbL coating; (C) a broad range of the release profile from LBL coating can be achieved by tuning the chemical structure of the cationic polymer used for LBL assembly. Figure adapted from ref. 72.