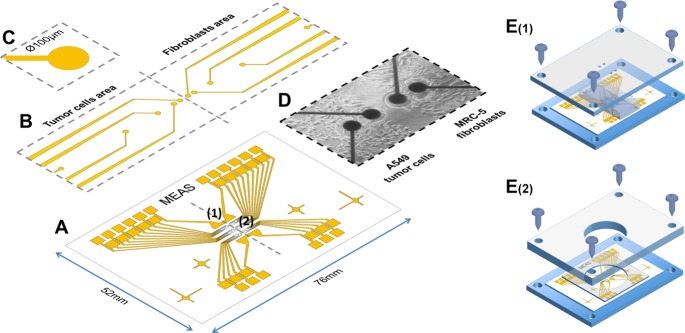

Fig 1.

(A) Microelectrode arrays (1: working electrode, 2: common counter electrode) were fabricated on experimental glass slides (76mm x 52mm) by common photolithography processes. SU-8 photoresist was used as passivation layer to cover the conducting traces. (B) The sensing platform was divided into 2 areas, one for the cancer cells and one for microenvironment agents. Several mirco-sized working electrodes were installed in each area at different distances: 100, 250, 650, 1450 and 3050μm far from the confrontation line. (C) A single electrode was 100μm in diameter. (D) An image of a real chip after the co-culturing of 2 different cell types on 2 sides. (E) The co-culture patterning process using a dual-chamber mold. (E1) After treating the surface for cell culture, the cell chip was placed on the designed fixture, and the dual-chamber mold was fixed at the proper location by screws. The 2 chambers were separated each other by a 100μm thick wall for cell patterning. (E2) After the cells in both chamber had attached to the chip surface, the dual-chamber mold was replaced by a well-type open reservoir. A PDMS bed was also installed to prevent solution from leaking. The cell chip was connected to the measurement system and was kept in the incubator during the measurements.