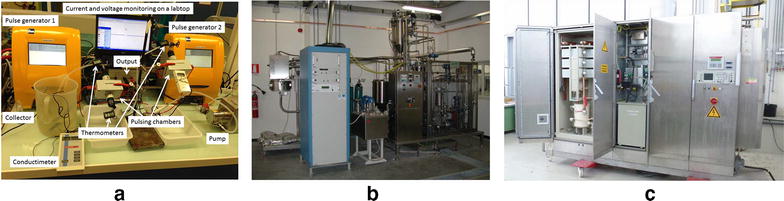

Fig. 5.

a Laboratory scale PEF system. Trains of two successive 2 kV 1(one) ms long pulses with opposite polarities are delivered at a 1 Hz frequency by 2 pulse generators on an array of pulsing chambers where a flow of cells is passing through at a 4 l/h rate. Measurement and control auxiliaries are indicated. b Pilot scale continuous flow (max flow rate 300 l/h) plant available at laboratory of ProdAl Scarl (University of Salerno, Italy) for PEF treatment of liquid biomass. It comprises, a DTI pulse generator (20 kV, 20 kW, square and bipolar pulses, 1–10 μs pulse width, 1–1000 Hz), four co-linear treatment chamber (0.32 cm inner diameter, 0.43 cm electrode gap), pump, heat exchanger, and storage tanks. c Pilot facility operative at KIT/IHM (Karlsruhe; Germany) for PEF treatment of dense cell suspensions at a mass flow of 400 l/h. Rectangular-shaped pulses of 65 kV and a duration of 1 µs are provided at a repetition frequency of 10 Hz, left section. The power supply is situated in the middle section. Measurement and control auxiliaries are installed in the closed right section

Figure a adapted from [132]