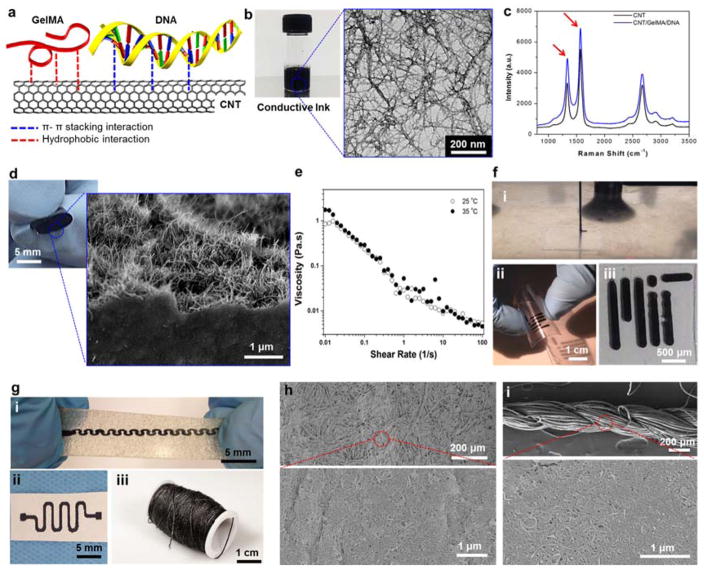

Figure 1. Formation and characterization of the electrically conductive ink and its utilization.

(a) Schematic diagram showing the GelMA/DNA-coated MWCNT inks formed though hydrogen bonding, hydrophobic interactions, and π-π stacking interactions between MWCNT and GelMA/DNA. (b) Photograph of black conductive ink and HRTEM image of individual or bundled GelMA/DNA-wrapped MWCNTs. (c) Raman spectrum of the MWCNTs and GelMA/DNA-coated MWCNTs. (d) Representative images of highly flexible hybrid films after rolling and an magnified SEM image showing a cross-section of MWCNTs coated with GelMA/DNA. (e) Viscosity dependence as a function of shear rate for GelMA/DNA-coated MWCNT inks. (f) Photograph of (i) nozzle-based printing using a glass capillary (ii) on a PEG coated PET film, and (iii) cellulose paper substrate. (g) Screen printing on (i) stretchable hydrocolloid substrate and (ii) cellulose paper (iii) dip coating on cotton thread. (h) SEM image of screen printed cellulose paper by GelMA/DNA-coated MWCNT ink. (i) SEM image of uniformly covered GelMA/DNA-coated MWCNT ink on a cotton thread.