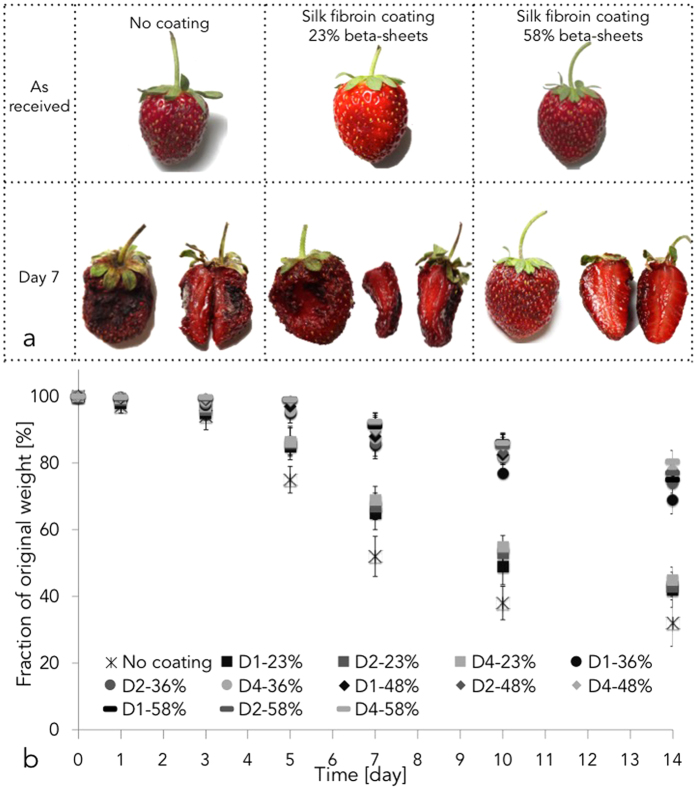

Figure 2. Ripening and weight loss of strawberries coated with edible silk fibroin coating.

(a) Time-lapse of strawberries ripening. As picked strawberries were stored at 22 °C and 38% RH (no coating) or dip coated in silk fibroin suspension (23% beta-sheets coating). Water annealing was used as post-process to modulate the relative content of beta-sheets in silk fibroin. At day 7, silk fibroin coating showed to improve the quality of the stored strawberries. (b) Weight loss of strawberries stored for up to 14 days at 22 °C and 38% RH. Strawberries were stored as picked (i.e. no coating) or after coating with silk fibroin suspension (Dx-xx%). Dx stands for ‘x’ dip coating steps. xx% stands for relative amount of beta-sheet content. (e.g. D1-23% means that strawberries were dip coated with silk fibroin materials with 23% beta-sheets content). One-way ANOVA test with Tukey mean analysis was used to evaluate the weight loss data. Silk beta-sheet content (which is proportional to water-annealing time) but not number of dip coating steps affected the dehydration of the strawberries considered. No coating controls lost circa 70 wt% of their original weights in the 14 days considered (highlighted within the red rectangles). Strawberries coated silk fibroin retained more water than the no coating controls at day 3 (p <D 0.05). An increase in silk fibroin beta-sheets content via water annealing process further decreased fruit dehydration compared to non-water annealed counterparts (p <D 0.05) and to the no coating controls (p <D 0.05) but no statistically significant difference was found between samples with a beta-sheet content ≥D 36% (p >D 0.05).