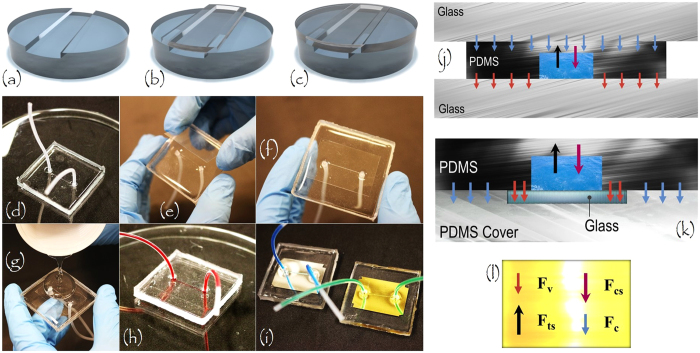

Figure 1. Steps of microfabrication and actuation of forces in devices.

PDMS substrate with microchannel obtained by replica molding (a,d); reversible enclosing of microchannel with glass coverslip (b,e,f); pouring of PDMS cover onto previous structure (g); and cure of this cover resulting in a stacked structure of PDMS/glass/PDMS sandwich (c,h). Substrate integrated silicone tubes for fluid pumping (d). SWB was applied for prototyping PDMS/Al and PDMS/Au as well (i). Forces in reversible bonded microdevice composed of glass/PDMS/glass sandwich structure (j) and SWB PDMS/Glass device (k). Discrimination of the force vectors that act over the devices (l). Nomenclature: Fv, Force related to van der Waals interactions responsible for PDMS/glass self-adhesion; Fts, tensile stress force from liquid; Fcs, compressive stress force from PDMS; and Fc, counterforce applied by glass cover in (j) and PDMS cover in (k).