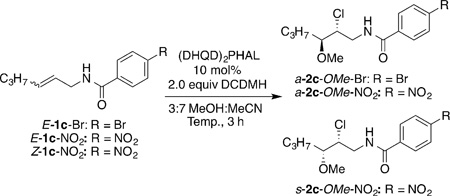

Table 2.

Reaction optimization for aliphatic substrates.[a]

| |||||

|---|---|---|---|---|---|

| Entry | Substrate | Temp [°C] | Product | Yield [%][b] | e.r.[d] |

| 1 | E-1c-Br | −30 | a-2c-OMe-Br | 92[c] | 81:19 |

| 2 | E-1c-NO2 | −30 | a-2c-OMe-NO2 | 86 | 87:13 |

| 3 | Z-1c-NO2 | −30 | s-2c-OMe-NO2 | 87 | 99.5:0.5 |

| 4 | Z-1c-NO2 | 24 | s-2c-OMe-NO2 | 75 | 97:3 |

| 5[e] | Z-1c-NO2 | −30 | s-2c-OMe-NO2 | 79 | 97:3 |

The r.r. (defined as ratio of 2:5, see Table 4) was more than 20:1 and d.r. was more than 99:1 in all instances.

Determined by NMR using MTBE as added external standard.

5% of cyclized product was also seen by NMR.

Determined by chiral-phase HPLC.

2 mol% catalyst was used.