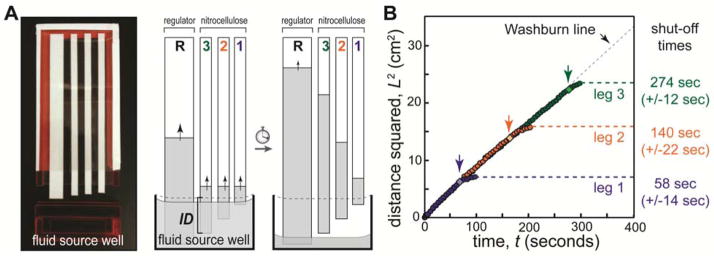

Figure 1.

Volume-limited well for programmed fluid shut off. A) Nitrocellulose legs (width 5 mm) were arranged on an adhesive plastic backing (cartridge) such that each leg protruded a different length. An optional high capacity cellulose regulating wick (width 1 cm) was added to increase the rate of fluid depletion from the well and to humidify the device. The source well (1 cm tall, 5 cm wide, 2.5 mm thick) was filled with buffer (PBST), and the cartridge was inserted to initiate flow. The cartridge interior thickness (air gap) was 1.5 mm. The leg immersion depth (ID) is indicated for leg 3; immersion depths were 3.5 mm, 4.5 mm, 5.5 mm for legs 1, 2, and 3, respectively. As fluid was wicked, each leg broke contact with the fluid in a timed sequence to provide programmed shut off. B) Plot of the fluid front position in each leg as a function of time. The fluid front in each leg followed Lucas-Washburn (L2=Wt) until it broke contact with the fluid in the well (indicated by light diamonds and arrows). The fluid front migrated somewhat after disconnection due to relaxation of fluid into the dry membrane. Relative errors in shut off times were 20%, 15%, and 5% for legs 1, 2 and 3, respectively.