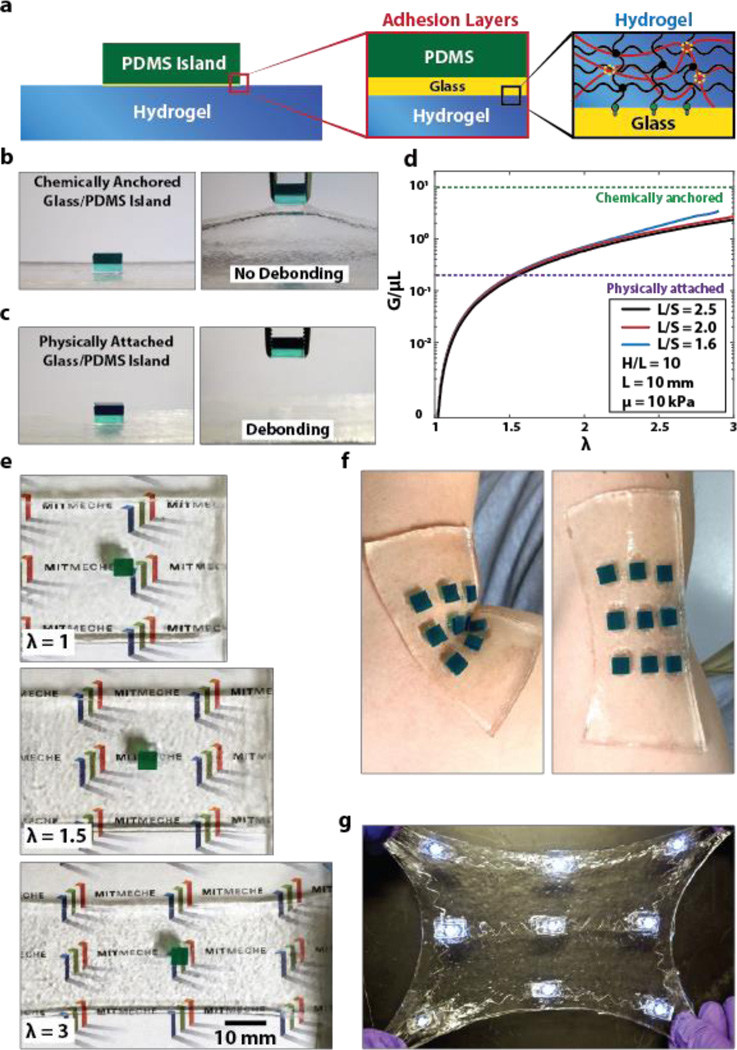

Figure 3. Integration of rigid chips on the surface of (or inside) tough hydrogel matrix.

a) Schematic illustration of a rigid PDMS chip bonded on the surface of hydrogel. Glass slide is used to form stable and robust adhesion layer between PDMS chip and tough hydrogel. Oxygen plasma treated PDMS and glass slide surface are covalently bonded through siloxane bond, while silanization of the glass slide gives tough covalent bonding to hydrogel. b) Chemically anchored Glass/PDMS chip is robustly bonded on hydrogel matrix even when pulled by a tweezer. c) Physically attached Glass/PDMS chip is easily debonded from hydrogel matrix. d) Chemically anchored Glass/PDMS chip doesn’t debond from hydrogel matrix even under high stretch (up to 3 times) due to robust adhesion between adhesion layers. e) The calculated G/µL from the finite-element model is plotted as functions of λ and S/L. The typical values of interfacial toughness between chips and hydrogels with and without silanized interfaces are also given for comparison (1000 J/m2 and 20 J/m2 respectively). f) A sheet of hydrogel (thickness ~ 1.5 mm) with multiple patterned chips can conformably attach to different regions of human body and survive deformation due to body movements. g) A hydrogel electronic device that encapsulates an array of LED lights connected by stretchable silanized titanium wire. The device is transparent, and robust under multiple cycles of high stretch.