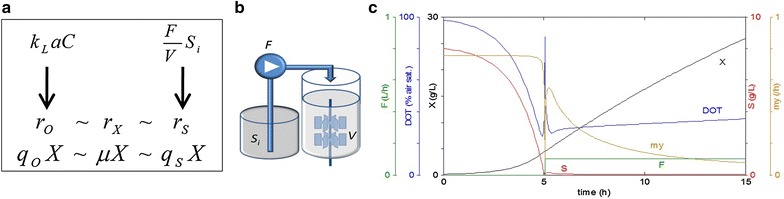

Fig. 1.

Overview of the fed-batch principle. a The oxygen transfer capacity kLaC in a bioreactor limits the volumetric oxygen consumption rate rO if aerobic conditions need to be maintained. Due to the relationship between the volumetric rates for growth (rX), substrate consumption (rS) and oxygen (rO), rO can be controlled by a control of the volumetric substrate uptake by a controlled substrate feed (F Feed rate, V reactor volume, Si substrate concentration in the feed solution). As the volumetric rates are the product of the specific rates (qO, μ, qS) with the actual biomass X, at a constant feed rate the specific rates decrease at increasing biomass and thus the level of dissolved oxygen is dependent on the feed rate, but largely independent on the cell density. b Principle view of a fed-batch bioreactor with a feed reservoir and the fee pump which controls the fee rate. c A typical simulation plot for a fed-batch cultivation on mineral salt medium with glucose as the only carbon source and a constant feed rate. The graph shows the Feed rate (F), dissolved oxygen tension (DOT), biomass (X), Substrate (S, often glucose) and the specific growth rate (my)