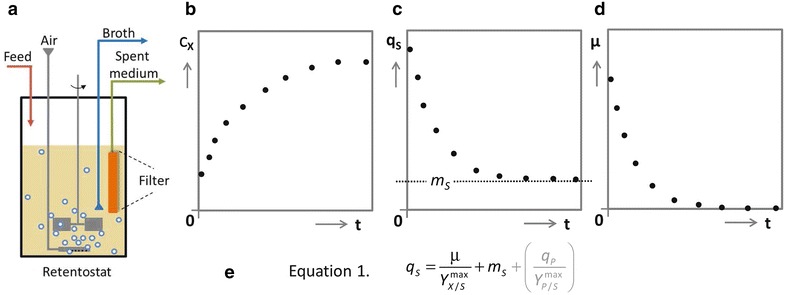

Fig. 1.

Schematic representation of retentostat set-up and simulated profiles of biomass accumulation (CX), glucose consumption rate (qS) and specific growth rate (µ) during prolonged retentostat cultivation. The retentostat is a continuous bioreactor system in which the outflow can be switched from whole-broth removal to complete cell retention through a filter probe (a). After switching from chemostat cultivation to retentostat mode, biomass accumulates in the bioreactor (b), which gradually decreases the glucose availability per unit of biomass. This decrease ultimately results (c) in specific glucose consumption rates that can only meet energy demands for cellular maintenance (mS), thereby causing near-zero specific growth rates (d). The distribution of the carbon and energy source over growth, maintenance and product formation (not indicated in the plots) is mathematically captured by an extended Pirt equation (e), in which YmaxX/S is the maximum theoretical biomass yield, qP is the specific production rate of a product whose synthesis requires metabolic energy, and YmaxP/S is the maximum theoretical yield of this product on substrate