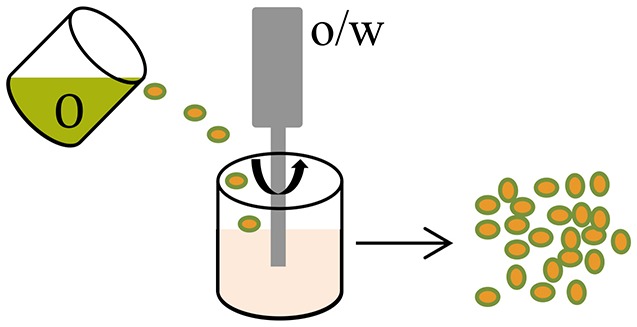

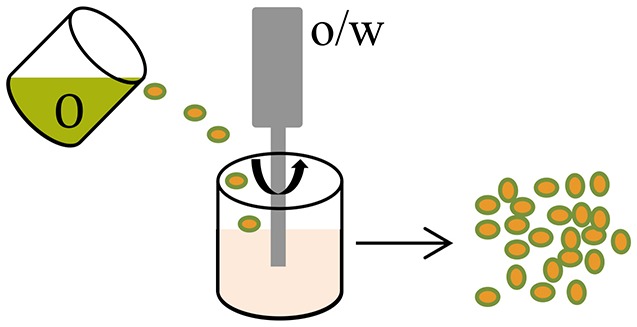

| Oil-in-water (o/w) emulsion |

|

|

Low encapsulation efficiency especially for water-soluble payloads Solvent residuals Low yield, agglomeration of sticky particles

|

Varde and Pack, 2004

|

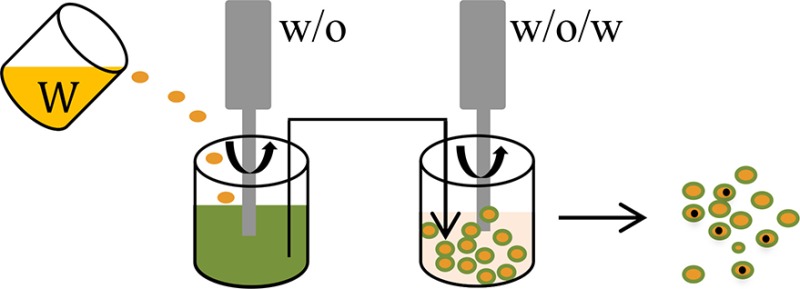

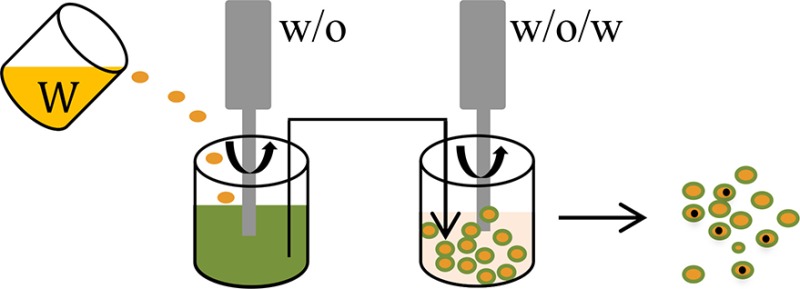

| Water-in-oil-in-water (w/o/w) emulsion |

|

|

|

|

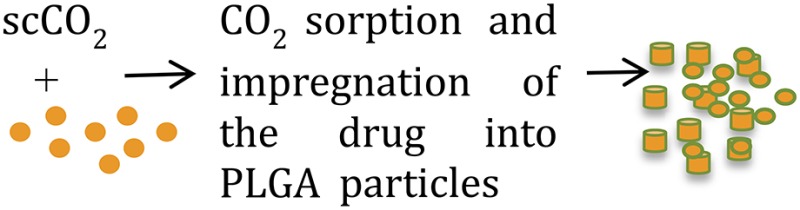

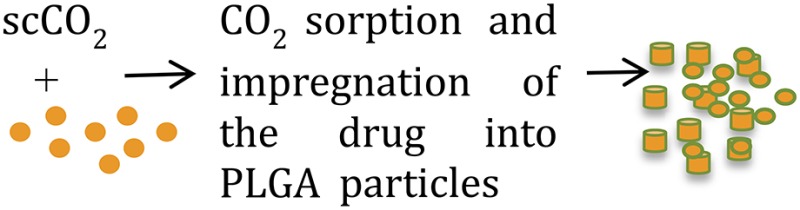

| Supercritical CO2 (scCO2) |

|

|

|

Falco et al., 2012; Dhanda et al., 2013

|

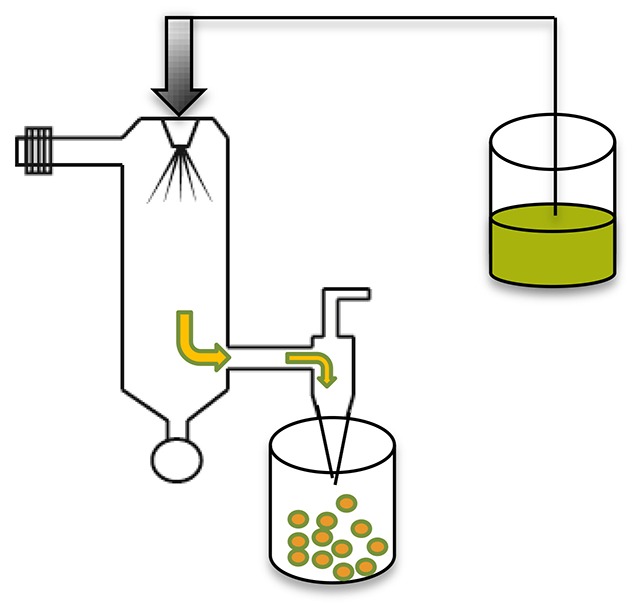

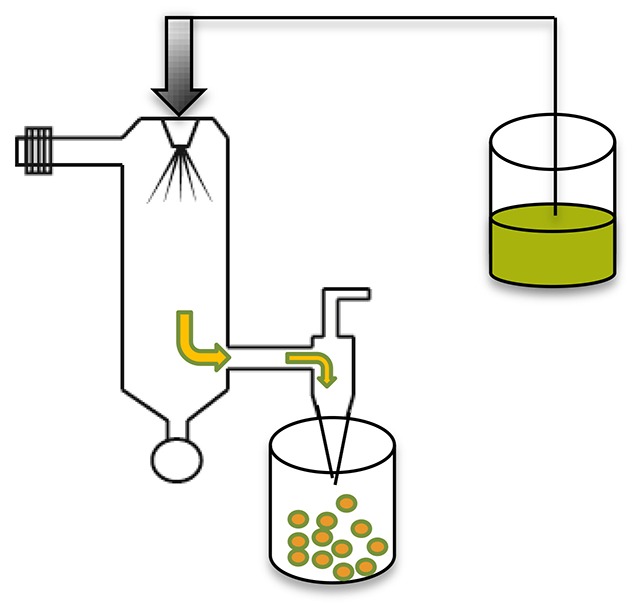

| Spray drying |

|

Can encapsulate wide range of drugs/peptides/proteins into microparticles without significant loss Final drying step not required One step and reproducible Atomizers (nozzles) eliminate the need for complicated pre-preparation processes and enable continuous manufacture by utilization of liquid feeds via two separate channels

|

Adhesion of microparticles to inner walls of the spray-dryer Not suitable for temperature-sensitive compounds Difficult to control particle size Low yield, agglomeration of sticky particles

|

Makadia and Siegel, 2011; Sosnik and Seremeta, 2015; Wan and Yang, 2016

|

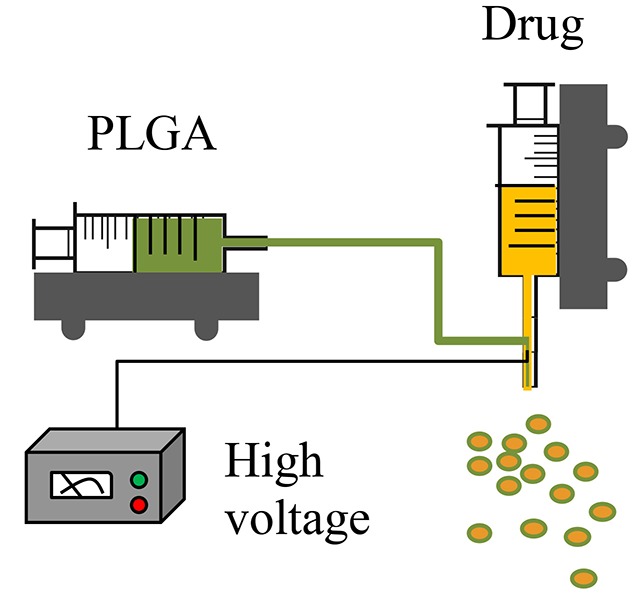

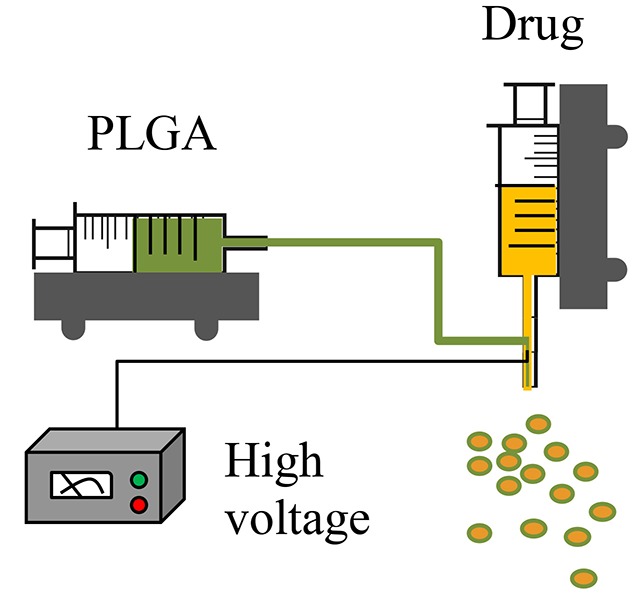

| CES (Other modification, such as, coaxial tri-capillary electrospray, Emulsion-coaxial electrospinning) |

|

Nearly 100% encapsulation rate Useful for encapsulating water-soluble molecules Protects biologically active payloads from processing-induced damage Potential to control particle morphology with flexibility and reproducibility for both micro- and nanoparticle size ranges

|

At early stage; requires further development Standardized protocols and systematic process controls not available as yet Lack of an effective particle collection method; commonly used one-step collection methods cannot facilitate shell hardening, or maintain particle morphology or prevent particle aggregation Lack of a more productive nozzle design

|

Lee et al., 2011; Viry et al., 2012; Zhang et al., 2012; Zamani et al., 2014; Yuan et al., 2015

|

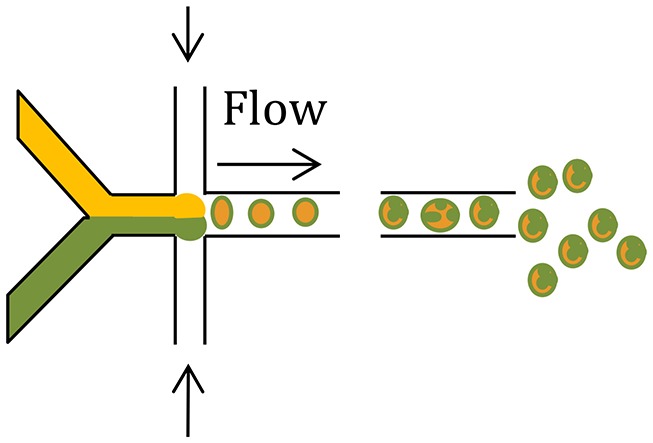

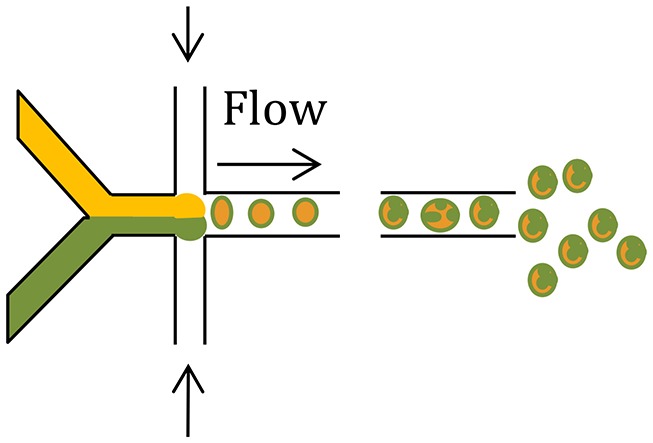

| Microfluidics (Other modification, such as, capillary microfluidics coupled with solvent evaporation) |

|

Ultra-small quantities of reagents needed Precise control over drug release rate, drug loading efficiency, particle shell thickness, particle shape and size Multiple components are easily generated using single-step emulsification

|

|

Demello, 2006; Hung et al., 2010; Xie et al., 2012; Cho and Yoo, 2015; Leon et al., 2015

|

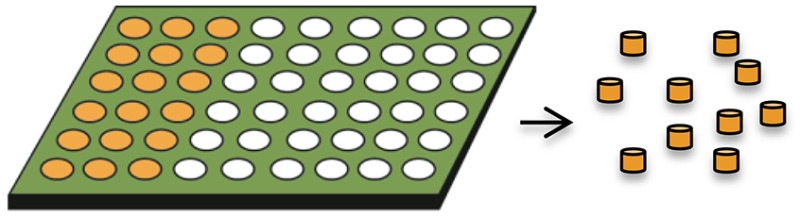

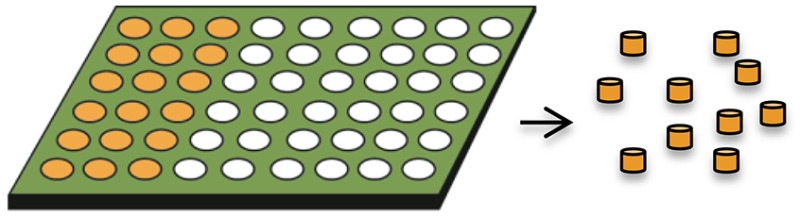

| Hydrogel template |

|

|

|

Acharya et al., 2010a,b; Malavia et al., 2015

|