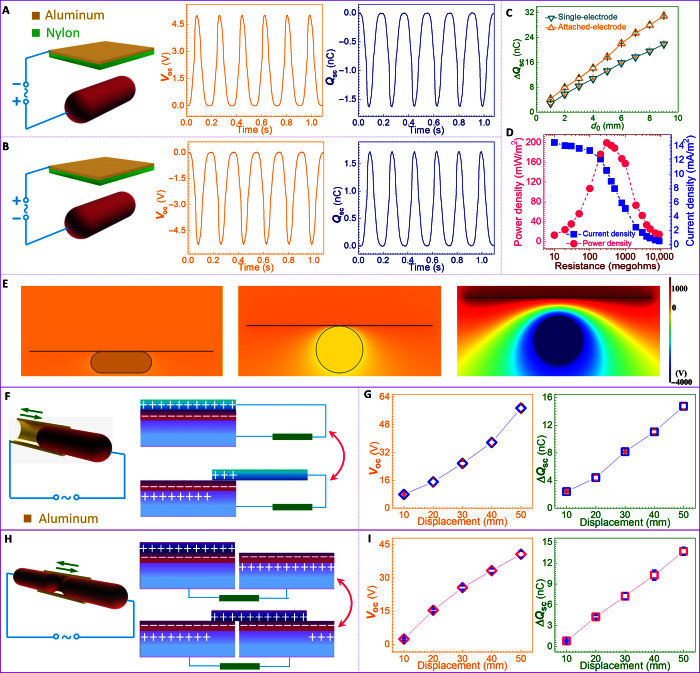

Fig. 2. Investigation of the saTENG unit working in other modes.

(A and B) The open-circuit voltage (Voc) and short-circuit transferred charge (Qsc) of the attached-electrode contact-mode saTENG with (A) forward connection and (B) reverse connection to the liquid electrode. (C) Comparison of the ΔQsc of the saTENG working in the single-electrode mode and attached-electrode mode (contact/release motion, d1 = 5 mm). (D) Load matching test of the saTENG working in the attached-electrode contact mode at a frequency of ~3 Hz. Maximum average output power is obtained at a matched load of ~300 megohms. (E) Simulation results for the attached-electrode contact-mode saTENG exhibit the increasing electrical potential difference between the liquid electrode and the aluminum electrode as the distance between the rubber and nylon increases. Note that for simplification, the acrylic plate support under the saTENG unit is omitted in the simulation model, which will not affect the changing trend of the electrical potential due to the superposition principle of electrical potential. (F and G) Working mechanism (F) and dependence (G) of Voc and ΔQsc on the sliding displacement for the saTENG unit operating in the attached-electrode sliding mode. (H and I) Working mechanism (H) and dependence (I) of Voc and ΔQsc on the parallel-moving displacement for the saTENG unit operating in the freestanding mode.