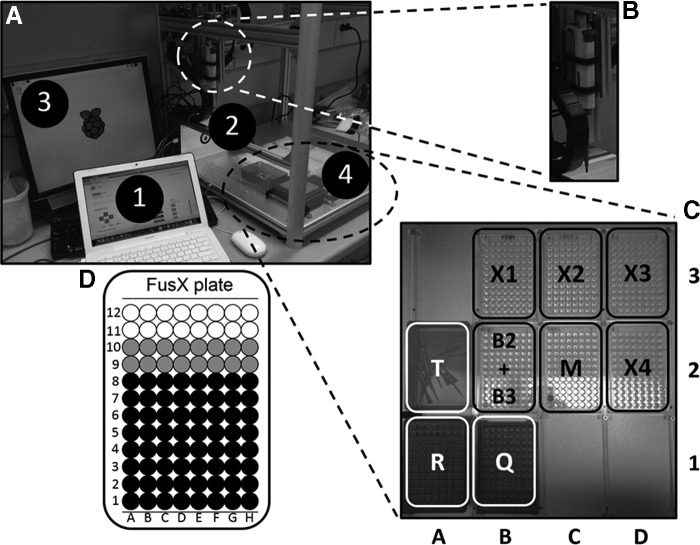

Figure 2.

Enhanced FusX assembly using an automated liquid-handling laboratory automation tool. (A) OT-One liquid-handling robot (LHR) set up for TALEN (transcription activator-like effector as nuclease) arm assembly via the FusX system. The MacBook laptop (1) operates the graphical user interface of the LHR software running on a Raspberry Pi 2 (RPi) single-board computer. (2) The RPi takes the JSON script of an arbitrary protocol and parses it into a G-code job to be run by the Smoothieboard numerical controller. (3) A monitor connected to the RPi via HDMI to visualize the RPi OS (GNU/Linux 8.0). (4) LHR workspace. (B) DRAGONLAB 10-μl micropipette. (C) Zoom-in on LHR workspace. Black border: six 96-well plates containing the libraries FusX1–4, Fus_B2+B3, and an extra plate (M) with the receiver backbone plasmid and the pLR plasmid stocks. White border: 10-μl tip rack (R), trash bin (T), and destination aliquots for TALEN arm assembly (Q). (D) Organization of the FusX 96-well plates. In black, all 64 possible combinations of RVD array plasmids were arranged on the basis of the output from the Mojo Hand inventory-management software for TALEN arm assembly for libraries FusX1–4 and Fus_B3. In gray, the 16 extra wells for plasmids of the Fus_B2 library in the pFusB2+B3 plate.