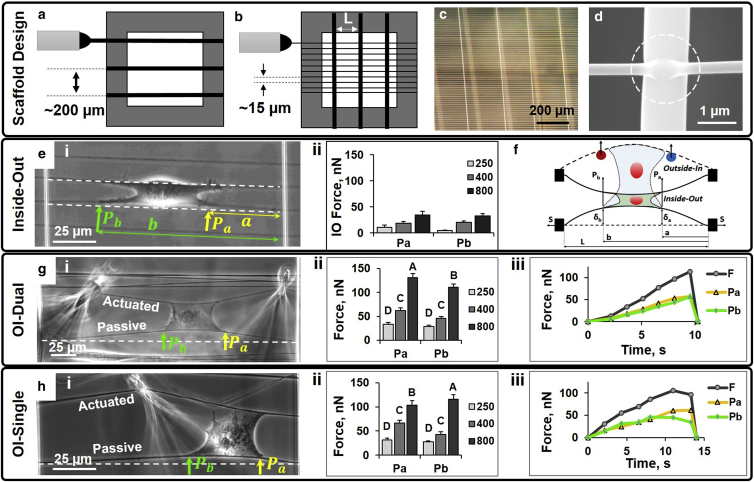

Figure 1.

(a) Schematic of large-diameter fibers (∼1200 nm) spun with interfiber spacing (∼200 μm) over a hollowed-out substrate, resulting in suspended fibers; (b) schematic of small diameter fibers spun with spacing (∼15 μm) perpendicular to the first layer; (c) optical image of an assembled nanonet; (d) fiber intersections are fused together, resulting in fixed boundary conditions; (e) IO force measurement, showing (i) representative parallel cell and (ii) forces Pa and Pb for different fiber diameters; (f) schematic of IO and OI modes showing use of two point load model and selection of locations for a and b; (g) OI-Dual platform, with (i) representative optical image, (ii) force distribution, and (iii) representative force-time plot of abrupt breaking failure with resultant force calculated as ; and (h) OI-Single platform, with (i) representative optical image, (ii) force distribution, and (iii) representative force-time plot of peeling failure. Letters above bars represent groups of statistical significance. Shared letters indicate insignificant differences (n = 242). White dashed lines indicate undeflected fiber position. To see this figure in color, go online.