Abstract

Unreduced gluten proteins of Indian wheat varieties viz.C306, DBW16, HI977 and HW2004 were separated using size-exclusion chromatography (SEC). Statistical correlation of area % of eluted peaks with properties of flour, dough and noodles was elucidated. Chromatograms of gluten proteins were classified primarily into five peaks in decreasing molecular size range and relative proportion were expressed in terms of area % of individual peaks which depicts the quantitative variation in protein eluted at different retention times. Cooking time and cooked weight of noodles depicted positive correlation with peak I and negative correlation with peak II which predominantly composed of glutenins and gliadins, respectively. Oil uptake and cooking loss were negatively association with peak I and positively with peak II. Noodle hardness, springiness, cohesiveness and chewiness were positively correlated with peak I and negatively to peak II, though adhesiveness was unaffected by SEC eluted peaks statistically.

Keywords: Size exclusion chromatography, Chromatograms, Noodles, Gliadins, Glutenins

Introduction

Noodles are the most favourite among the Asian population due to good taste, nutrition, convenience, longer shelf-life and reasonable price. In the year of 2014, 102.7 billion servings of instant noodles were eaten regardless of age and gender on this earth. By considering noodles as “comfort food” Indian population secured the fourth place in all Asian countries and consumed 5340 million packs of instant noodles in the year of 2015 (Source: World Instant Noodles Association). Texture being the prime attribute to noodle’s acceptance which is primarily rely upon functional properties of wheat flour constituents mainly protein and starch. Barak et al. (2013a) reported that gluten proteins were mainly held responsible for the differences in the noodle making quality of the wheat varieties. Wheat protein quality and quantity have been found to have radical contribution in producing the high quality noodles (Barak et al. 2013a, b; Park et al. 2003). Noodles hardness and surface smoothness were found to relate positively with protein content of flour (Park et al. 2003). The firmness and elasticity of noodles was significantly affected by change in gluten properties of flour (Baik and Lee 2010; Gulia and Khatkar 2014). Yamauchi et al. (2007) deduced that hardness and elasticity had significant alliance with strong proteins possessing HMWGS 5 + 10, 17 + 18 and high protein contents.

Dough rheological attributes are other indices of protein composition of flour which relates to noodle quality. Noodles prepared from dough with higher values of extensigraph maximum resistance and increased farinograph stability were more elastic and harder in bite (Crosbie et al. 1999). Barak et al. (2013a); Gulia and Khatkar (2014) showed that higher cohesiveness and chewiness during bite demonstrated the positive relationship with prolonged development and stability time of dough. It has been reviewed that glutenin and gliadin fractions individually influence the finished product quality (Khatkar et al. 2013, 2002a; Uthayakumaran et al. 2000). Park et al. (2003) stated that the hardness of noodles was inversely affected by the amount of salt soluble proteins. Kaur et al. (2015) demonstrated the strong relationships of physico-chemical properties of durum flours with gliadins and glutenins and alliance of secondary structure of storage proteins with noodles textural attributes. Influence of gluten protein fractions on noodle quality has not been accentuated much previously. Ohm et al. (2006) investigated SE-HPLC chromatography of wheat proteins and multivariate analyses that provided useful predictions of dough mixing and noodle characteristics for hard and soft winter wheat varieties and distinction between hard and soft wheat varieties.

In this study the relative area % of eluted peaks was elucidated using SEC on Fast Protein Liquid Chromatography (FPLC) in order to determine the fitness of elite commercial Indian wheat varieties for noodle making. Indian wheat cultivars varies noticeably in their gluten protein composition and technological quality due to diverse genetic make, environment and crop duration as compared to European and Western wheat cultivars (Singh and Singh 2010; Singh et al. 2011). The specific objectives of this study was to demonstrate the correlation studies of relative area % of peaks with properties of flour, dough and properties of instant noodles which included textural parameters and cooking quality prepared from selected wheat varieties to illustrate the relative impact of gluten proteins on noodles quality.

Materials and methods

Materials

Wheat varieties

Four wheat varieties (Triticum aestivum) elite among the choices, namely C306, DBW16, HI977 and HW2004 which are the hard, medium hard, hard and soft varieties respectively. Distinct Wheat Directorates, Wheat Research Stations, and State Agricultural Universities were provided 1 kg of each variety for experimentation, harvested in the year of 2013 and 2014. The wheat varieties were selected on the basis of diverse processing quality as demonstrated from the physicochemical properties and divergent Glu1 score. The wheat grains cleaned manually to remove soil particles and broken and shrivelled seeds, and stored in closed steel containers at 4 °C until used further.

Chemicals

The chemicals used in this study were of analytical reagent grade. Acetone, Acetic acid, Acrylamide, Ammonium persulphate, Ammonium sulphate, Boric acid, Bromophenol blue, Chloroform, Coomassie brilliant blue (CBB) G-250, Copper sulphate, Ethanol, Glycerol, Glycine, Hydrochloric acid, Methanol, 2- Mercaptoethanol (2-ME), N, N′- Methylene bisacrylamide (bisacrylamide), N, N, N′, N′- Tetramethylenediamine (TEMED), Sodium acetate anhydrous, Sodium chloride, Sodium dodecyl sulphate (SDS), Sodium hydroxide, Sulphuric acid, Urea.

Methods

Grain and flour properties

Grain hardness of all the wheat varieties was determined on Single Kernel Characterization System (Model 4100, Perten Instruments, Huddinge, Sweden) as perstandard AACC (2000) procedures. The samples were tempered at 15.5 g/100 g moisture for 24 h and milled by using Chopin laboratory mill (Model CD1, Villeneuve la Garenne, France). Crude protein contents of flour were determined by standard AACC methods (2000). SDS Sedimentation values of flours were estimated according to Axford et al. (1979). Damaged starch was evaluated by the Chopin SDmatic (AACC 76-33) which works on the basis of the absorption of iodine by the damaged starch in a diluted suspension of flour. The quantity of absorbed iodine is measured with an amperometric method. The reaction mixture containing 3 g boric acid, 3 g potassium iodide and 1 drop of 0.1 mol/l sodium thiosulphate in 120 ml distilled water was mixed and poured into the reaction bowl. Weighed flour sample (1 g) was taken in a sample pan and fixed into the sample pan holder for 10 min till the test procedure get completed. After completion results of damaged starch were displayed. Falling number was estimated by Falling Number apparatus (Perten instruments).

Dough rheological properties

Rheological characteristics of dough were investigated using Chopin Mixolab with 50 g flour sample by adopting Standard ‘‘Chopin S’’ protocol. It determines a comprehensive qualitative profile of the wheat flour and plots, in real time, the torque (expressed in Nm) produced by mixing dough between two kneading arms with a constant mixing speed of 80 rpm. The information recorded from the curves contained the percentage of water required for dough to produce a torque of 1.1 ± 0.07 Nm i.e. water absorption (%); the time to reach maximum torque at 30 °C i.e. dough development time (min); the slip away time at which the torque produced is maintained at 1.1 Nm i.e. dough stability (min); the difference between the maximum torque at 30 °C and the torque at the end of holding time at 30 °C i.e. mechanical dough weakening recorded in Farinograph Units (FU), was used to evaluate the rheological characteristics of various flours.

Fractionation of gluten proteins

Wheat flours were defatted by successive extraction with chloroform according to MacRitchie (1987). Flour (100 g) was defatted using 200 ml of chloroform, filtered through filter paper at room temperature and the process was repeated thrice. The defatted flour was dried at room temperature. Gluten yield and gluten index were estimated by Glutomatic (Model GM 2200, Perten Instruments). Gluten extensibility test was performed with a TA-XT 2i Texture Analyzer (Stable Micro System) using Kieffer dough/gluten extensibility rig with the test speed of 3.3 mm/s and data acquisition rate of 200 pps. The test mode of the instrument used was force in tension. Gluten was dried using lyophilizer. The lyophilized gluten was ground to uniform powder and separated into gliadins and glutenins by adopting modified Osborne (1907) method. Gluten powder (50 g) was suspended in 1 L of 70 % (v/v) ethanol and stirred for 3 h at room temperature (~22 °C) on a magnetic stirrer followed by centrifugation at 1000 × g for 30 min in centrifuge at 4 °C. The extraction was repeated thrice. The precipitant was collected as glutenin and the supernatant was subjected to rotary evaporator at 30 °C to remove ethanol to get the gliadins. Resulted glutenins and gliadins were subjected to freeze-drying.

Noodle making

Instant noodles were prepared using the standardized formulation and processing conditions (Gulia and Khatkar 2013). The ingredients in noodle recipe (on 100 g flour basis) comprised of water (30.97 %), alkaline salt (0.23 %) (Potassium carbonate and sodium carbonate, 1:1), guar gum (0.28 %) and salt (1.54 %). Noodle dough was thoroughly mixed by incorporating wheat flour with all other ingredients dissolved in water using mixer (Kitchen Aid Inc., Michigan, USA) for 4 min. Crumbled dough was then sheeted using noodle machine (ATLAS, Marcato, Italy) by passing it four times through roller no. 1 and compounding it after every pass. A resting period of 10 min was given to the dough sheet in zip lock pouch to prevent surface moisture loss and later passed over through roller unit attachment five times to get a final thickness of 1.2 mm with a regulating knob set at position no. 2, 3, 4 and 5, respectively. Resting period of final sheeted dough was 30 min and dough sheet was sent to cutter attachment to get the desirable shape of noodles. The culminated noodles were stowed uniformly on a sieve and steamed into a preheated steamer (Rice Cooker-Ultimate, UL-255, China) at 100° C for 6.4 min. Steamed noodles were fried in soybean oil at 142 °C for 2 min in deep fat fryer (Friendz, FZ-591, China) and cooled for 15 min. The samples were stored in air-tight containers at 4º C for further analysis.

Cooking quality

Oil uptake was calculated according to the approved AACC (2000) method. Instant fried noodles were ground evenly and oil was extracted with petroleum ether (60–80 °C) using a solvent extractor (SER148, VelpScientifica, Usmate, Italy). Oil uptake was expressed in terms of percentage on dry basis. Cooked weight of noodles was measured as per the procedure of Oh et al. (1983). Fried noodles (10 g) were put into 400 ml of boiling water, cooked to the optimal cooking time and subsequently cooled for 1 min under running tap water. Ultimately, the noodles were reweighed and stocked in a capped petriplate at room temperature for texture analysis. The total water remaining after cooking in addition to that utilized for rinsing was collected to estimate cooking loss. An aliquot of 50 ml was evaporated in an oven at 100 °C for 4 h and outcome was recorded as per cent weight loss during cooking. The cooked weight was measured as exhibited by Wang et al. (2011) as per cent enhancement in weight of noodles after cooking.

Texture analysis

Texture profile analysis of cooked noodles was demonstrated using Texture Analyzer TA-XT 2i within 15 min after cooking. Pre-test speed, test speed and post-test speed used were 2.0, 3.0 and 3.0 mm/sec, respectively with the compression plate probe of 45 × 30 mm. Five noodle strands were placed closer to each other in flat position. The texture analysis results were presented as noodle hardness, springiness, adhesiveness, cohesiveness and chewiness.

Size-exclusion chromatography

Sample preparation and chromatography was performed as explained by Chaudhary et al. (2016) Gluten was extracted in solvent containing 3 M urea and acetic acid was added to maintain buffer pH 4.6. After dissolving the sample well, it was sonicated (Power Sonic 410, Hwashin Technology) for 30 min to increase the sample extraction, centrifuged at 12,000 × g for 30 min (Remi Cooling Centrifuge) and filtered through syringe filter (0.22 μm HV Millipore, DuraPore). SEC was performed on Sephacryl S-200 column (HI PrepTM16/60 SephacrylS-200 HR, GE Healthcare) by using FPLC system. The mobile phase was 3 M Urea, 0.15 M NaCl, pH 4.6 with a flow rate of 0.5 ml/min. Selected eluted protein fractions were then assayed by SDS-PAGE as described by Laemmli (1970).

Statistical analyses

Data was analysed using SPSS software version 16.0 (SPSS Inc.). Correlation among various quality characteristics of kernel, flour, dough, gluten, area % and finished product were derived using Pearson’s test (p < 0.05). The mean comparison was carried out using one way ANOVA with Duncan’s multiple range test and the statistical significance was observed at p < 0.05.

Results and discussion

Wheat quality analyses

The protein content has been the primary factor for determination of end-use quality of a wheat variety as it contributes to the strength of gluten network depending on their quantity and quality which defines the functional properties of the dough. All the varieties varied significantly in protein content, falling number, SDS sedimentation volume and damaged starch content. HI977 had higher protein content (12.43 %) and maximum SDS sedimentation volume (62 ml) while HW2004 had minimum protein content (8.68 %) and the least SDS sedimentation volume (35 ml). Quantitative and compositional variation of gluten proteins is the vital factor for imparting desirable dough structure by assimilating other components inside and forming three-dimensional framework. SDS sedimentation volume differed slightly among C306 and DBW16, but protein content (12.56 %) was found maximum in C306. Damaged starch content ranged from 5.92 g, the highest in DBW16 to 6.87 g, the lowest in C306 owing to the kernel hardness of the respective wheat varieties (Rahman et al. 2000). Falling number data indicated that HW2004 had the highest amylase activity, while C306 had the lowest.

HMW-GS composition and gluten quality parameters

It is evident that C306 and HW2004 had significantly different gliadin content (6.1 and 6.5 g, respectively), glutenin content (3.9 and 3.5 g, respectively) and dry gluten content (11.7 and 7.8 g, respectively) although they had the similar HMW-GS composition and Glu-1 scores. Gluten index expresses the strength of wheat gluten and it was maximum (98.7) for HI977 while minimum (61.6) for HW2004. R/E ratio of glutens varied considerably from 0.38 to 1.49, being the highest for HI977 and the lowest for C306. HI977 and DBW16 had different R/E ratio (1.49 and 0.58, respectively) and gluten index (98.7 and 77.8, respectively), yet possess alike HMW-GS composition at Glu-A1 (2*) and Glu-D1 (5 + 10), with only difference at Glu-B1 loci expressing subunit 17 + 18 and 7 + 8, respectively (Kasarda 1999; Katyal et al. 2016). These differences in gluten quality parameters can be referred to the variation in total protein contents of all the wheat varieties. These results illustrated that the higher glutenin levels, as in HI977, gave rise to elastic dough, conferring dough strength and a high R/E ratio. However, DBW16, C306 and HW2004 possessing higher gliadin content contributed to the extensibility of the dough, thereby, lowering R/E ratio and increasing gliadin/glutenin ratio.

Dough rheological characteristics

It was evaluated from the observations that the water required to reach peak dough consistency was lesser for DBW16, HW2004 and HI977 i.e. 53.7, 55.97 and 56.73 %, respectively while it was maximum for C306 i.e. 62.4 %. Dough strength parameters differed significantly among varieties being the highest for HI977 followed by DBW16, C306 and HW2004. Elevated dough strength properties of HI977 and DBW16 can be explained as flour having HMW-GS 2*, 5 + 10, 7 + 8 and 17 + 18 are associated with higher dough development time and dough stability, while flours (C306 and HW2004) with subunits Null, 2 + 12 and 20 resulted in dough with lower stability and higher weakening. HI977 and DBW16 contained higher Glu-1 score of 10 while C306 and HW2004 possessed lower Glu-1 score of 4. It is important to note that Glu-1 score or HMW-GS composition may not be the primary reason for symmetrical rheological properties but the relative proportion of gliadin and glutenin may also be equally important parameter for dough strength of wheat varieties. HI977 developed the strongest dough with 7.38 min of mixing time which remained stable for 10.80 min due to the presence of the highest amount of glutenin and the lowest amount of gliadin. On the contrary, HW2004 required the least time to develop (1.89 min) with minimum stability (4.06 min) and the highest dough weakening (109 FU). This could be attributed to the presence of maximum amount of gliadin and the lowest amount of glutenin, which resulted in formation of poor gluten network. These observations were in conformance with the studies of (Khatkar et al. 2002a), who revealed that addition of gliadin rich fractions to the base flour cutback the dough development time and dough stability. Flour sample of HI977 exhibited the rheological characteristics of extra strong flour, greater dough stability and lower protein degradation or weakening while HW2004 could be characterized weak on the basis of rheological outcome.

Gluten proteins distribution pattern of wheat varieties

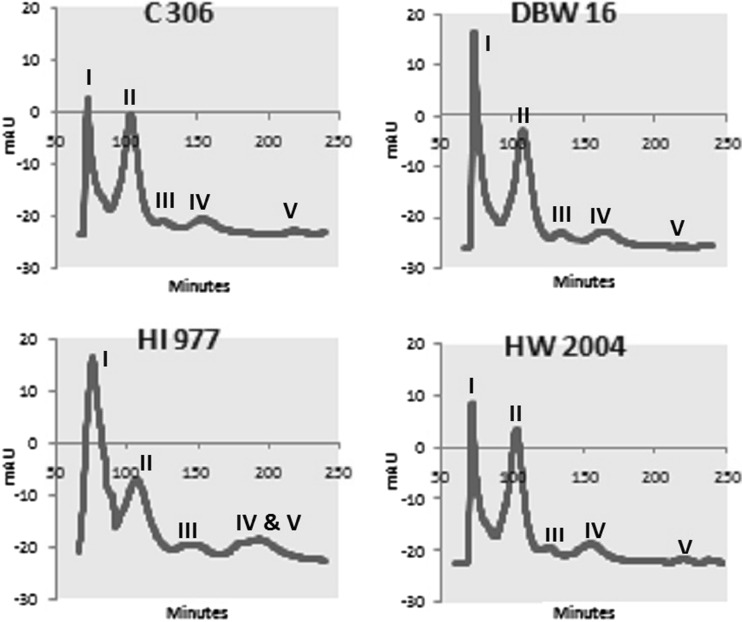

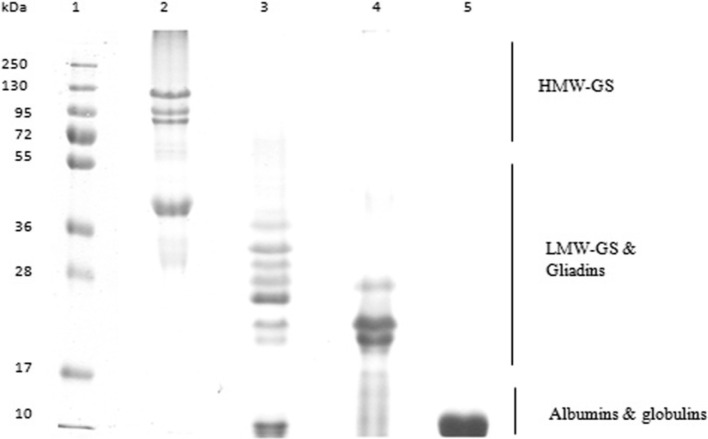

Size-exclusion chromatograms of unreduced gluten proteins (Fig. 1) were divided predominantly into five peaks and expressed in terms of area % of absorbance of individual peak which depicted the quantitative variation in protein eluted at different retention time. Gluten proteins extracts were fractionated in two primary peaks and three smaller peaks in decreasing molecular size range. As per the electrophoretic pattern of these eluted peaks as shown in Fig. 2 (Chaudhary et al. 2016), peak I symbolizes glutenins (130–30 kDa), eluted at 66.33–70.67 min. Monomeric gliadins were eluted relatively whole in peak II with minor amount of LMW-GS (55–20 kDa) at 102.67–108.33 min. In the end, at 126.33–133.00 min, small and flattened peak III comprehended very low molecular weight monomeric gliadins (28–10 kDa), subsequently, peak IV and peak V eluted albumins and globulins (<10 kDa) at 140.00–154.67 and 212.00–227.33 min, respectively, in very less proportion (Chaudhary et al. 2016; Ohm et al. 2009b, Singh et al. 1990a).

Fig. 1.

Size-exclusion chromatograms of unreduced gluten protein extract of four wheat varieties and numbers are given to the peaks (I, II, III, IV and V)

Fig. 2.

Electrophoretic profiles of unreduced gluten protein extracts of HI977 eluted from SEC. Lane 1-Marker; Lane 2-Peak I; Lane 3-Peak II; Lane 4-Peak III; Lane 5-Peak IV and V

All varieties performed distinct on SEC and manifested diverse trend in peak I and peak II. C306 and HW2004 possessed higher area % in peak II (55.47 and 54.35, respectively) in comparison to peak I (35.63 and 36.64, respectively) which typified the presence of higher quantity of gliadin comparatively. DBW16 contained somewhat different elution profile from other wheat varieties. DBW16 had the least difference in the area % of peak I (43.87) and peak II (47.86) and slight decrease in the relative quantity of peak I was depicted which was a glutenin rich fraction, that might be responsible for its reduced dough strength in comparison to HI977 (Barak et al. 2013a). Dough with such type of composition could withstand sheeting due to ability of protein matrix to bear stress and avoid the development of cracked surface. Additionally, recoiling of the noodle sheet could also be prevented by the virtue of sufficient amount of gliadins (Gulia and Khatkar 2014). HI977 had maximum area % in peak I (47.34) and minimum area % in peak II (38.93). Lateral eluted protein fractions has not been considered much important in relation to end-product quality, also the area % of peak III (very LMW monomeric proteins) and peak IV, V (albumins and globulins) was very less.

Interrelationships among gluten, rheological characteristics and area % of wheat gluten proteins

Table 1 depicts the statistical interplay among flour, gluten and rheological parameters with SEC peak area %. It was of interest to see whether SEC could provide a possibility for relating dough strength and end usage attributes. A significant positive correlation of area % of peak I and peak III with SDS sedimentation volume (r = 0.818** and r = 0.757**, respectively), gluten index (r = 0.959** and r = 0.796**, respectively), dough development time (r = 0.830** and r = 0.664*, respectively) and dough stability (r = 0.901** and r = 0.685*, respectively). On the contrary, gliadin/glutenin ratio had a negative statistical significance with peak I (r = −0.952**) and peak III (r = −0.913**) and positive with peak II (r = 0.948**). Discriminately, R/E ratio had positive correlation with peak I (r = 0.745**), negative with peak II (r = −0.869**) and no correlation with peak III. This observation is marked to the presence of HMW-GS in peak I which might provide conditions conducive for extensive cross-linking and branching, in effect, raising the average molecular size of the polymer, and hence the dough elasticity and strength. Verbruggen et al. (2001) stated that addition of HMW-GS caused a significant increase in mixing time and dough strength. However, gliadins exert a plasticizing effect by interfering with the glutenin–glutenin interactions and resulted in lowering the elasticity of gluten proteins (Khatkar and Schofield 1997).

Table 1.

Correlation of flour, gluten quality characteristics and dough rheology with area % of SEC chromatograms

| PC | Glu | Gli | Peak I | Peak II | Peak III | Peak IV | Peak V | |

|---|---|---|---|---|---|---|---|---|

| SDSV | 0.749** | 0.948** | −0.948** | 0.818** | −0.893** | 0.757** | 0.615* | 0.737* |

| R/E | ns | 0.771** | −0.771** | 0.745** | −0.869** | ns | 0.872** | 0.934** |

| GI | ns | 0.989** | −0.989** | 0.959** | −0.994** | 0.796** | 0.585* | 0.727** |

| Gli/Glu | −0.658* | −0.992** | 0.992** | −0.952** | 0.948** | −0.913** | ns | ns |

| WA | ns | ns | ns | −0.765** | 0.624* | −0.639* | ns | ns |

| DDT | 0.602* | 0.942** | −0.942** | 0.830** | −0.930** | 0.664* | 0.744** | 0.851** |

| DS | ns | 0.959** | −0.959** | 0.901** | −0.979** | 0.685* | 0.722** | 0.839** |

| DW | ns | −0.997** | 0.997** | −0.969** | 0.985** | −0.854** | ns | −0.663* |

PC Protein content; Glu Glutenin; Gli Gliadin; SDSV Sedimentation volume; R/E Resistance to extensibility to extension ratio; GI Gluten index; Gli/Glu Gliadin to glutenin ratio; WA Water absorption; DDT Dough development time; DS Dough stability, DW Dough weakening and ns non significant

* Correlation is significant at the 0.05 level. ** Correlation is significant at the 0.01 level

Assessment of noodles quality with area % of SEC chromatograms

Cooking quality

The differences in the quality traits of instant noodles prepared from different varieties have been summarized in Table 2. Noodles were examined to assess their correlation studies of oil uptake, cooking quality (cooking time, cooked weight and cooking loss) with various analytical attributes in Table 3. Oil uptake and cooking loss in noodles were positively influenced by gliadin/glutenin ratio (r = 0.787** and r = 0.911**, respectively) and negatively influenced by gluten index (r = −0.658* and r = −0.909**, respectively). However, the parameters like SDS sedimentation volume and R/E ratio were not significantly correlated with oil uptake but negatively affected the cooking loss (r = −0.730** and r = −0.681*, respectively). Peak I and peak III were negatively correlated with oil uptake (r = −0.806** and r = −0.959**, respectively) and cooking loss (r = −0.989** and r = −0.872**, respectively) while peak II exerted a positive correlation with these parameters. Association of polymeric glutenins with cooking loss indicates that polymeric gluten proteins’ fibrils retain the starch granules intact in the thin “sheets” or “cells” in the noodle structure and therefore avoid the excessive leaching of starch molecules during cooking (Rao 1999). Similar results for decrease in oil uptake of noodles with greater protein content and protein quality in terms of SDS sedimentation volume has been proposed by other researchers (Wu et al. 2006). Kaur et al. (2016) reported that a stronger gluten network results in a less permeable outer layer that may serve as an effective barrier against absorption of oil. Although flours with lower protein content exhibits formation of coarser globules on noodle surface during steaming which allows for greater penetration of oil during frying (Moss et al. 1987). Cooking loss was positively influenced by the damaged starch content (r = 0.693*) and water absorption (r = 0.846**) which reflects that damaged starch instantly absorbs the water, swell, rupture and leach out readily due to heat and α-amylase activity.

Table 2.

Cooking and textural characteristics of instant noodles of different wheat varieties

| C 306 | DBW 16 | HI 977 | HW 2004 | |

|---|---|---|---|---|

| OU (%) | 21.75c | 17.97a | 19.62b | 22.66d |

| CT (min) | 2.45b | 3.29c | 3.28c | 2.30a |

| CW (g/100 g) | 200.70b | 201.87c | 210.13d | 191.73a |

| CL (%) | 17.72d | 14.88b | 14.37a | 17.13c |

| HD (N) | 39.82b | 40.25c | 44.40d | 35.70a |

| SP | 1.32b | 1.26a | 1.41c | 1.32b |

| CO | 1.22a | 1.21a | 1.24b | 1.20a |

| AD (N/s) | −0.32a | −0.15b | −0.32a | −0.16b |

| CH (N) | 64.13c | 61.87b | 77.59d | 56.53a |

OU Oil uptake; CT Cooking time; CW Cooked weight; CL Cooking loss; HD Hardness; SP Springiness; CO Cohesiveness; AD Adhesiveness and CH Chewiness

Values followed by different letters are significantly different at p < 0.05

Table 3.

Correlation of flour quality, gluten protein characteristics, dough rheology and area % of SEC chromatograms with instant noodle quality

| Analytical attributes | Cooking quality | Textural parameters | |||||||

|---|---|---|---|---|---|---|---|---|---|

| OU | CT | CW | CL | HD | SP | CO | AD | CH | |

| PC | −0.845** | ns | 0.844** | ns | 0.834** | ns | 0.619* | −0.730** | 0.708** |

| SDSV | ns | 0.754** | 0.981** | −0.730** | 0.986** | 0.696* | 0.886** | −0.658* | 0.984** |

| FN | −0.722** | ns | ns | ns | ns | ns | ns | 0.709** | ns |

| DaS | 0.887** | −0.750** | ns | 0.693* | ns | ns | ns | 0.611* | ns |

| R/E | ns | ns | 0.598* | −0.681** | 0.619** | 0.845** | 0.705* | ns | 0.772** |

| GLU | −0.717** | 0.897** | 0.930** | −0.907** | 0.931** | ns | 0.820** | ns | 0.896** |

| GLI | 0.717** | −0.897** | −0.930** | 0.907** | −0.931** | ns | −0.820** | ns | −0.896** |

| GLI/GLU | 0.787** | −0.933** | −0.940** | 0.911** | −0.938** | ns | −0.799** | ns | −0.865** |

| GI | −0.658* | 0.863** | 0.887** | −0.909** | 0.893** | 0.629* | 0.821** | ns | 0.889** |

| WA | 0.764** | −0.764** | ns | 0.846** | ns | ns | ns | ns | ns |

| DDT | ns | 0.704** | 0.921** | −0.741** | 0.932** | 0.797** | 0.884** | −0.614* | 0.983** |

| DS | ns | 0.759** | 0.868** | −0.833** | 0.879** | 0.751** | 0.834** | ns | 0.927** |

| DW | 0.729** | −0.904** | −0.912** | 0.924** | −0.914** | ns | −0.799** | ns | −0.881** |

| Peak I | −0.806** | 0.948** | 0.801** | −0.989** | 0.800** | ns | 0.672* | ns | 0.739** |

| Peak II | 0.651* | −0.858** | −0.842** | 0.927** | −0.848** | −0.617* | −0.780** | ns | −0.853** |

| Peak III | −0.959** | 0.976** | 0.833** | −0.872** | 0.818** | ns | ns | ns | 0.632* |

| Peak IV | ns | ns | ns | ns | 0.609* | 0.977** | 0.653* | −0.602* | 0.728** |

| Peak V | ns | ns | 0.599* | ns | 0.624* | 0.972** | 0.741** | −0.594* | 0.824** |

OU Oil uptake; CT Cooking time; CW Cooked weight; CL Cooking loss; HD Hardness; SP Springiness; CO Cohesiveness; AD Adhesiveness; CH Chewiness; PC Protein content; SDSV Sedimentation volume; FN Falling number; DaS Damaged starch; R/E Resistance to extensibility to extension ratio; Glu Glutenin; Gli Gliadin; Gli/Glu Gliadin to glutenin ratio; GI Gluten index; WA Water absorption; DDT Dough development time; DS Dough stability; DW Dough weakening and ns non significant

* Correlation is significant at the 0.05 level. ** Correlation is significant at the 0.01 level

Instant noodles prepared from the weaker flours of C306 and HW2004 cooked quickly, rough surface developed and exhibited higher oil uptake in comparison to stronger flours of HI977 and DBW16 (Saguy et al. 1998). Cooking time was positively correlated with SDS sedimentation volume (r = 0.754**) and gluten index (r = 0.863**), whereas negatively correlated with gliadin/glutenin ratio (r = −0.933**). Correlation results of cooking time of noodles depicted the assertiveness with peak I (r = 0.948**) and peak III (r = 0.976**) and diffident with peak II (r = −0.858**). These results suggest that association of polymeric proteins with starch polymer resists the faster hydration of noodles by affecting the availability of water during cooking and extend the cooking time. Cooking time followed a negative association with damaged starch (r = −0.750**) and water absorption (r = −0.764**) which indicates that damaged starch content is one of the important factor which supports to decline the cooking time of the noodles. Noticeably, noodles with lower cooking time tend to have poor textural stability in hot water with higher cooking loss as for HW2004. Cooked weight of noodles was positively correlated with area % of peak I (r = 0.801**) and peak III (r = 0.833**) and negatively correlated with peak II (r = −0.842**). Moreover, cooked weight had positive statistical relation with test parameters such as SDS sedimentation volume (r = 0.981**), R/E ratio (r = 0.598*) and gluten index (r = 0.887**) although negatively influenced by gliadin/glutenin ratio (r = −0.940**).

Cooking time and cooked weight were positively influenced by dough development time (r = 0.704** and r = 0.921**, respectively) and dough stability (r = 0.759**and r = 0.868**, respectively). Thus, wheat varieties with stronger dough properties such as DBW16 and HI977 yielded noodles with desirable, firm and elastic noodle texture which kept the noodle strands firm and discriminated during and after cooking.

Textural properties

Correlation studies of textural properties (hardness, springiness, cohesiveness, adhesiveness and chewiness) with various analytical attributes are resided in Table 3. Hardness of noodles was positively correlated with protein content (r = 0.834**), SDS sedimentation volume (r = 0.986**), R/E ratio (r = 0.619*), gluten index (r = 0.893**), dough development time (r = 0.932**) and dough stability (r = 0.879**). However it was negatively linked with gliadin/glutenin ratio (r = −0.938**) in accordance with the studies of (Park et al. 2003). Hardness of noodles was positively influenced by peak I (r = 0.800**) and peak III (r = 0.818**), however negatively influenced by peak II (r = −0.848**). Concurrent results were reported by Hu et al. (2007) that the noodle hardness is significantly affected by the soluble and insoluble glutenin content of the wheat flour. DBW16 resulted into noodles with firm and elastic texture. Harder and more elastic noodles were prepared from HI977, interpreting that presence of highest quantity of glutenins leads to dense, tough and highly extensible gluten network. HW2004 and C306 exhibited weaker dough leading to excessive breakage of noodles and resulting in inferior quality of noodles.

Springiness reflects the elastic recovery of the product after a compression force has been removed. Springiness was assertively correlated to most of the protein quality measures such as SDS sedimentation volume (r = 0.696*), R/E ratio (r = 0.845**), gluten index (r = 0.629*), dough development time (r = 0.797**) and dough stability (r = 0.751**). In context to area % of SEC peaks, springiness was found to have a positive correlation with peak I (r = 0.609*) and negative correlation with peak II (r = −0.617*). HI977 produced highly springy noodles owing to the abundance of glutenins in peak I although DBW16 produced the least springy noodles due to the adequate proportion of peak I and II.

Adhesiveness was associated with the damaged starch content (r = 0.611*) and falling number (r = 0.709*). None of the primary peak from SEC data was significant with adhesiveness statistically. Adhesiveness is an undesirable parameter for noodle quality and is defined as the force required for separating the probe from noodle surface. Noodles obtained from HI977 were most sticky while less sticky noodles were obtained from DBW16.

Correlation representation demonstrated that cohesiveness and chewiness of noodles were associated with strength of gluten proteins and dough rheological characteristics of flour. They were positively correlated with protein content (r = 0.619* and r = 0.708**, respectively), SDS sedimentation volume (r = 0.886** and r = 0.984**, respectively), R/E ratio (r = 0.705* and r = 0.772**, respectively), gluten index (r = 0.821** and r = 0.889**, respectively), dough development time (r = 0.884** and r = 0.983**, respectively) and dough stability (r = 0.834** and r = 0.927**, respectively) and negatively correlated to gliadin/glutenin ratio (r = −0.799** and r = −0.865**, respectively). Cohesiveness and chewiness of noodles were positively influenced by peak I (r = 0.672* and r = 0.739**, respectively) and negatively by peak II (r = −0.780** and r = −0.853**, respectively). Cohesiveness and chewiness of noodles turned out to be a function of intermolecular linkage’s strength between protein and starch which subsidize noodle structure. Noodles of HI977 were observed most cohesive and chewy, although HW2004 produced noodles with poor eating or chewing qualities.

Conclusions

The area % of gluten protein fractions of all four wheat varieties segregated by SEC validated the compositional variations of wheat gluten proteins, as observed from the variation in molecular weight distribution. The heterogeneity of eluted gluten protein fractions strongly influenced the flour, dough and product quality parameters. Peak I was positively associated with R/E ratio, gluten index and SDS sedimentation volume and negatively associated with gliadin/glutenin ratio, although peak II recurred to an antagonistic. Peak I and II saliently affected dough rheological properties, positively and negatively, respectively. This study administered the significant associations of SEC peaks with the noodle quality characteristics. The wheat variety DBW16pursued minimum difference peak I (glutenins rich) and peak II (gliadins rich) but relatively higher proportion in peak I, produced the excellent noodles which propose that the suitable amount of glutenins is requisite for finished surface of the noodles with proper sheeting of the noodle dough. Peak I was noted detrimental for oil uptake and cooking loss and peak II favored these unsought quality parameters of noodles. However, cooked weight and cooking loss were enhanced with increment in peak I and undermined with elevation in peak II. Textural properties of noodles were more advantaged by peak I. Hardness, springiness, cohesiveness and chewiness of noodles were positively influenced by peak I, however negatively influenced by peak II. A firm and elastic texture has been adopted for noodles. Much harder, springier and chewy noodles were composed from HI977 in comparison to others, interpreting that the presence of highest quantity of glutenins leads to dense, tough and inextensible gluten network. HW2004 and C306 exhibited weaker dough leading to excessive breakage of noodles and resulting in inferior processing and eating quality of noodles.

References

- AACC . Approved methods of the American Association of Cereal Chemists. St. Paul: American Association of Cereal Chemists; 2000. [Google Scholar]

- Axford DW, McDermott EE, Redman DG. Note on the sodium dodecyl sulphate test of bread making quality: comparison with Pelshenke and Zeleny tests. Cereal Chem. 1979;56:582–584. [Google Scholar]

- Baik BK, Lee MR (2010) Effects of flour protein and starch on noodle quality. In Asian Noodles, pp 261–283: John Wiley & Sons, Inc

- Barak S, Mudgil D, Khatkar BS. Effect of compositional variation of gluten proteins and rheological characteristics of wheat flour on the textural quality of white salted noodles. Int J Food Prop. 2013;17:731–740. doi: 10.1080/10942912.2012.675611. [DOI] [Google Scholar]

- Barak S, Mudgil D, Khatkar BS. Relationship of gliadin and glutenin proteins with dough rheology, flour pasting and bread making performance of wheat varieties. J Food Sci Technol. 2013;51:211–217. [Google Scholar]

- Chaudhary N, Dangi P, Khatkar BS. Assessment of molecular weight distribution of wheat gluten proteins for chapatti quality. Food Chem. 2016;199:28–35. doi: 10.1016/j.foodchem.2015.11.106. [DOI] [PubMed] [Google Scholar]

- Crosbie GB, Ross AS, Moro T, Chiu PC. Starch and protein quality requirements of Japanese alkaline noodles (ramen) Cereal Chem. 1999;76:328–334. doi: 10.1094/CCHEM.1999.76.3.328. [DOI] [Google Scholar]

- Gulia N, Khatkar BS. Effect of processing variables on the oil uptake, textural properties and cooking quality of instant fried noodles. J Food Qual. 2013;36:181–189. doi: 10.1111/jfq.12029. [DOI] [Google Scholar]

- Gulia N, Khatkar BS (2014) Quantitative and qualitative assessment of wheat gluten proteins and their contribution to instant noodle quality. Int J Food Prop 18(8):1648−1663. doi10.1080/10942912.2013.805765

- Hu XZ, Wei YM, Wang C, Kovacs MIP. Quantitative assessment of protein fractions of Chinese wheat flours and their contribution to white salted noodle quality. Food Res Int. 2007;40:1–6. doi: 10.1016/j.foodres.2006.05.003. [DOI] [Google Scholar]

- Kasarda DD. Glutenin polymers: the in vitro to in vivo transition. Cereal Foods World. 1999;44:566–571. [Google Scholar]

- Katyal M, Virdi AS, Kaur A, Singh N, Kaur S, et al. Diversity in quality traits amongst Indian wheat varieties I: flour and protein characteristics. Food Chem. 2016;194:337–344. doi: 10.1016/j.foodchem.2015.07.125. [DOI] [PubMed] [Google Scholar]

- Kaur A, Singh N, Kaur S, Katyal M, Virdi AS, et al. Relationship of various flour properties with noodle making characteristics among durum wheat varieties. Food Chem. 2015;188:517–526. doi: 10.1016/j.foodchem.2015.05.009. [DOI] [PubMed] [Google Scholar]

- Kaur A, Singh N, Kaur S, Katyal A, Virdi AS, et al. (2016) Physicochemical and rheological properties of starch and flour from different durum wheat varieties and their relationships with noodle quality. J Food Sci Technol. doi:10.1007/s13197-016-2202-3 [DOI] [PMC free article] [PubMed]

- Khatkar BS, Schofield JD. Molecular and physicochemical basis of bread making properties of wheat gluten proteins. J Food Sci Technol. 1997;34:85–103. [Google Scholar]

- Khatkar BS, Fido RJ, Tatham AS, Schofield JD. Functional properties of wheat Gliadins. I. effects on mixing characteristics and bread making quality. J Cereal Sci. 2002;35:299–306. doi: 10.1006/jcrs.2001.0429. [DOI] [Google Scholar]

- Khatkar BS, Barak S, Mudgil D. Effects of gliadin addition on the rheological, microscopic and thermal characteristics of wheat gluten. Int J Biol Macromol. 2013;53:38–41. doi: 10.1016/j.ijbiomac.2012.11.002. [DOI] [PubMed] [Google Scholar]

- Laemmli UK. Cleavage of structural proteins during the assembly of the head of bacteriophage T4. Nature. 1970;227:680–685. doi: 10.1038/227680a0. [DOI] [PubMed] [Google Scholar]

- MacRitchie F. Evaluation of contributions from wheat protein fractions to dough mixing and breadmaking. J Cereal Sci. 1987;6:259–268. doi: 10.1016/S0733-5210(87)80063-2. [DOI] [Google Scholar]

- Moss R, Gore PJ, Murray IC. The influence of ingredients and processing variables on the quality and microstructure of Hokkien, Cantonese and instant noodles. Food Microstructure. 1987;9:63–74. [Google Scholar]

- Oh NH, Seib PA, Deyoe CW, Ward AB. Noodles. I. Measuring the Textural Characteristics of Cooked Noodles. Cereal Chem. 1983;60:433–438. [Google Scholar]

- Ohm JB, Ross AS, Ong YL, Peterson CJ. Using multivariate techniques to predict wheat-flour dough and noodle characteristics from size exclusion HPLC and RVA data. Cereal Chem. 2006;83:1–9. doi: 10.1094/CC-83-0001. [DOI] [Google Scholar]

- Ohm JB, Ross AS, Peterson CJ, Morris CF. Relationships of quality characteristics with size exclusion HPLC chromatogram of protein extract in soft white winter wheats. Cereal Chem. 2009;86:197–203. doi: 10.1094/CCHEM-86-2-0197. [DOI] [Google Scholar]

- Osborne TB. The proteins of the wheat kernel. Washington DC: Carnegie Inst; 1907. pp. 1–119. [Google Scholar]

- Park CS, Hong BH, Baik BK. Protein quality of wheat desirable for making fresh white salted noodles and its influences on processing and texture of noodles. Cereal Chem. 2003;80:297–303. doi: 10.1094/CCHEM.2003.80.3.297. [DOI] [Google Scholar]

- Rahman S, Batey IL, Cochrane MP, Appels R, Morel MH. Genetic alteration of starch functionality in wheat. J Cereal Sci. 2000;31:91–100. doi: 10.1006/jcrs.1999.0291. [DOI] [Google Scholar]

- Rao MA. Rheology of fluid and semi solid foods: principles and applications. Gaithersburg: Aspen Publishers; 1999. [Google Scholar]

- Saguy IS, Ufhein G, Livings S. Oil uptake in deep fat frying: review. Oleagineux Corps Gras Lipids. 1998;5:30–35. [Google Scholar]

- Singh S, Singh N. Effect of debranning on the physico-chemical, cooking, pasting and textural properties of common and durum wheat varieties. Food Res Int. 2010;43:2277–2283. doi: 10.1016/j.foodres.2010.07.016. [DOI] [Google Scholar]

- Singh NK, Donovan GR, Batey IL, MacRitchie F. Use of sonication and size-exclusion high performance liquid chromatography in the study of wheat flour proteins. I. Dissolution of total proteins in the absence of reducing agents. Cereal Chem. 1990;67:150–161. [Google Scholar]

- Singh S, Singh N, MacRitchie F. Relationship of polymeric proteins with pasting, gel dynamic- and dough empirical-rheology in different Indian wheat cultivars. Food Hydrocoll. 2011;25:19–24. doi: 10.1016/j.foodhyd.2010.05.001. [DOI] [Google Scholar]

- Uthayakumaran S, Stoddard FL, Gras PW, Bekes F. Effects of incorporated glutenins on functional properties of wheat dough. Cereal Chem. 2000;77:737–743. doi: 10.1094/CCHEM.2000.77.6.737. [DOI] [Google Scholar]

- Verbruggen IM, Veraverbeke WS, Delcour JA. Significance of LMW-GS and HMW-GS for dough extensibility: ‘addition’ versus ‘incorporation’ protocols. J Cereal Sci. 2001;33:253–260. doi: 10.1006/jcrs.2000.0353. [DOI] [Google Scholar]

- Wang F, Huang W, Kim Y, Liu R, Tilley M. Effects of transglutaminase on the rheological and noodle-making characteristics of oat dough containing vital wheat gluten or egg albumin. J Cereal Sci. 2011;54:53–59. doi: 10.1016/j.jcs.2011.02.010. [DOI] [Google Scholar]

- Wu J, Aluko RE, Corke H. Partial least-squares regression study of the effects of wheat flour composition, protein and starch quality characteristics on oil content of steamed-and-fried instant noodles. J Cereal Sci. 2006;44:117–126. doi: 10.1016/j.jcs.2006.05.008. [DOI] [Google Scholar]

- Yamauchi H, Ito M, Nishio Z, Tabiki T, Kim S-K, et al. Effects of high molecular weight glutenins on the texture of yellow alkaline noodles using near-isogenic lines. Food Sci Technol Res. 2007;13:227–234. doi: 10.3136/fstr.13.227. [DOI] [Google Scholar]