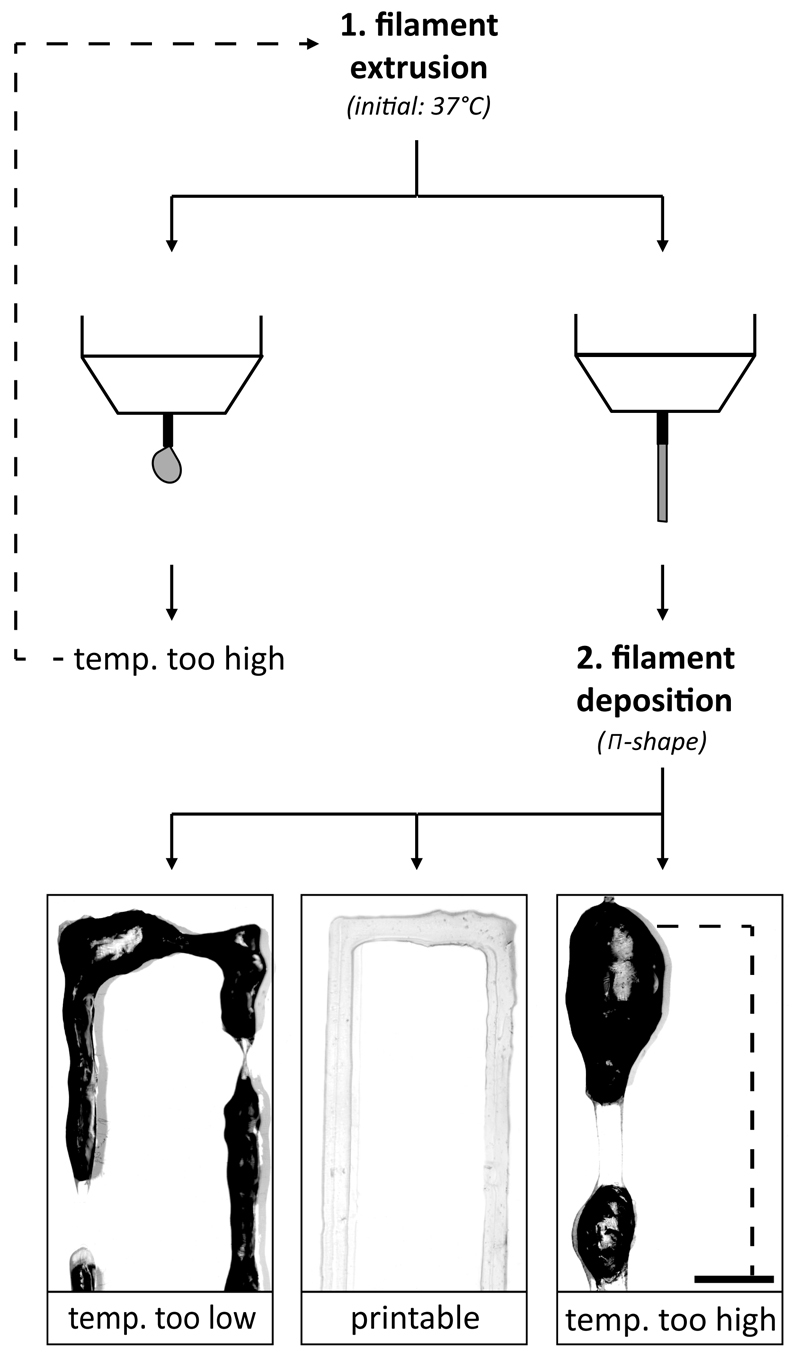

Fig. 2.

A schematic overview of the iterative hydrogel filament screening process. First filament extrusion was evaluated (1), when the temperature was too high (droplet formation) it was lowered and evaluated again, and when a certain temperature allowed filament extrusion, the appearance of the deposited filament was evaluated by printing a П-shape (2). The print temperature was adjusted until a smooth filament was formed or until an endless loop occurred which meant that the hydrogel formulation was unprintable at a temperature of 15-37°C. The irregularities of the filament surface cause light scatter, which turns black on the pictures. Scale bar represents 2 mm and the dotted line in the printed structures represents the missing part of the П-shape.