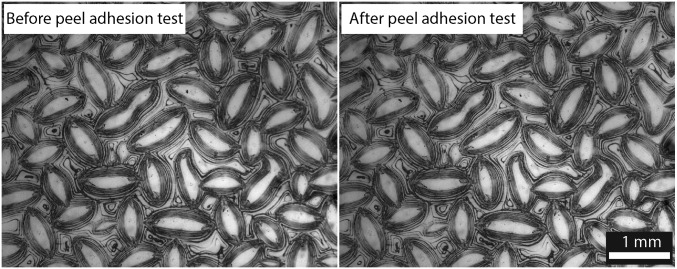

Fig. S3.

Peel adhesion test indicates good adhesion strength between the PEMA/POSS layer and the polyurethane elastomer. A strip of tape (3M 371 Carton Sealing Tape) is applied to a PEMA/POSS-coated polyurethane elastomer with finger pressure. The tape is peeled from the sample at a 180° angle. After the peel adhesion test, no apparent change is observed on the coated surface, implying good adhesion between the PEMA/POSS layer and the underlying polyurethane elastomer. PEMA acts as a compatiblizing layer between the POSS and the polyurethane surface that enhances the adhesion of hydrophobic fluorodecyl POSS molecules to the polyurethane elastomer. The low-energy POSS molecules reside preferentially at the free surface, whereas the PEMA chains interact with the polyurethane elastomer, creating a strong interface. Therefore, the interfacial tension between the PEMA/POSS layer and the PU elastomer is estimated to be , where is the surface energy of a typical poly(ether-urethane) (33) and is the surface energy of PEMA (33).