FIG. 1.

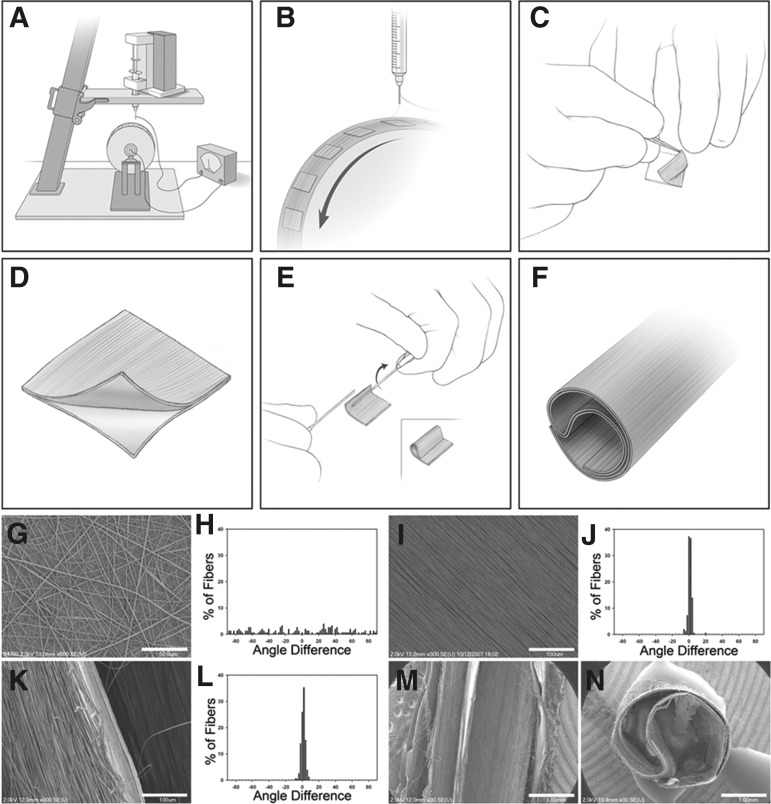

The panel A–F provides a schematic representation of conduit fabrication. PLLA fibers are electrospun onto coverslips coated with PLLA films on a rotating mandrel (A,B). The film and fibers are removed from the coverslip (C) and placed back-to-back, so the films meet, and are rolled into a conduit (D,E). The final conduit shape is shown as a schematic (F) and the lumen (M) and coronal view (N) are shown under Scanning electron microscopy (SEM.) Random fibers were produced by electrospinning onto a stationary target (G) while aligned fibers were produced using the rotating mandrel (I). Aligned fibers in the conduit maintained their alignment through the processing in steps C–E (K,L). The alignment for each group was determined by SEM imaging. Alignment was reported as a histogram of the angle differences from the median fiber orientation for 150 fibers per condition (H,J,L). Scale Bars: (G) 50 μm; (I, K) 100 μm; (M,N) 1 mm. This figure was reproduced from Hurtado and associates.45