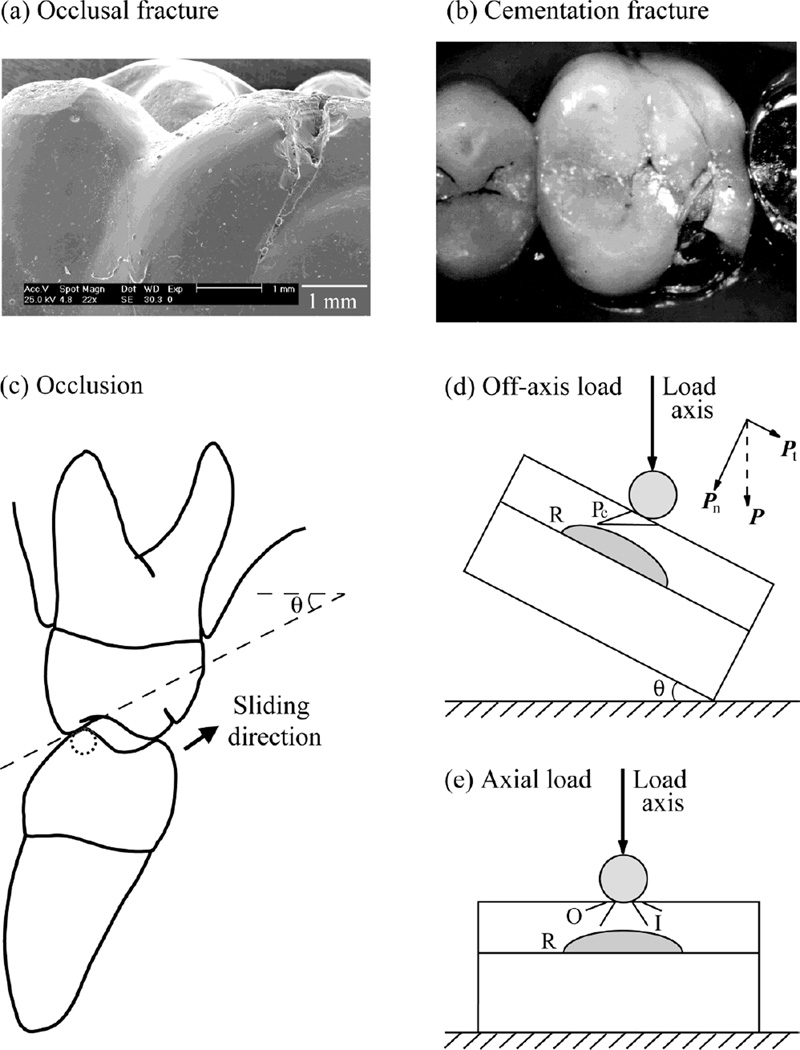

Fig. 1.

Fracture of porcelain veneered dental crowns: (a) occlusal failure of a Cerestore upper right first molar crown (pressed shrink-free 70% Al2O3 and 22% MgAl2O4 spinel framework veneered with aluminous porcelain) 19 years of intraoral service (Scherrer et al., 2001), and (b) bulk fracture from the cementation surface of an In-Ceram upper left first molar crown (glass infiltrated 95% Al2O3 framework veneered with aluminous porcelain) 3.5 years in service (Scherrer et al., 2001). The aluminous porcelain veneer comprised a combination of feldspath and alumina so that it’s coefficient of thermal expansion matched that of the respective cores. The occlusal surfaces of these crowns were glazed after adjusting the occlusion intraorally. The internal surfaces of the crowns were untreated prior to cementation using glass-ionomer cements. (c) Schematic of tooth eccentric occlusal position of right side first molar. Arrow indicates direction of sliding as teeth move to centric occlusion. Cuspal inclination slope and angulation (θ) are shown. (d) Experimental arrangement for indentation of brittle layer on compliant substrate with an inclination angle θ = 30° (Off-axis loading). Showing two crack modes: occlusal surface partial cone cracks (Pc), and cementation surface radial cracks (R). Note the superposed tangential force component. (e) Experimental control of axial loading (θ = 0°) of brittle layer on compliant substrate. Showing three crack modes: occlusal surface outer cone cracks (O) and inner cone cracks (I), and cementation surface radial cracks (R).