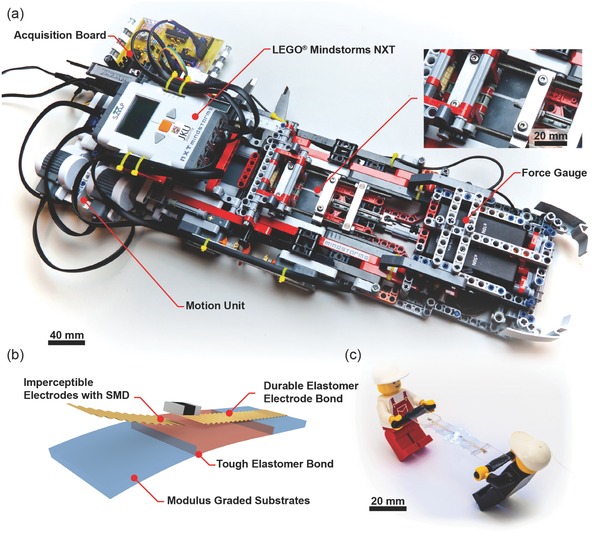

Figure 1.

a) Photo of the toy‐brick tensile testing setup. The only elements that are not made from toy bricks are the acquisition board, the clamping device and the digital caliper. The sample is placed in the clamping contraption (see inset for enlarged view) and stretched at constant velocity by the motion unit. b) Illustration of a tough, hybrid stretchable electronic system. PET foils (1.4 μm thick) bearing conductors and surface mounted devices (SMD) are covalently bonded to a prestretched, modulus‐tunable all‐elastomeric substrate with low viscoelasticity. Nonstretchable components (microcontrollers, light emitting diodes (LEDs), etc.) rest at strain‐insulated elastomer islands, the ultrathin PET with metallic interconnects is on deformable regions of the substrate. A reversibly stretchable network of folds and wrinkles forms upon relaxation of the prestretch. c) Hybrid stretchable blue SMD LED kept under tension by two LEGO helpers while operated.