Table 2.

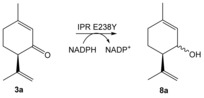

Biocatalytic reduction of cyclic ketones by enzyme variants IPR E238Y and MNMR Y244E.[a]

| Entry | Enzyme | Substrate | Product | Yield [%][b] | ee [%][b] |

|---|---|---|---|---|---|

| 1 pH 6 2 pH 7 | IPR E238Y IPR E238Y | 3 a 3 a | 8 a 8 a | <1 <1 | nd nd |

| 3 pH 6 4 pH 7 | IPR E238Y IPR E238Y | 1 a 1 a | 2 b 2 b | 38[c] 42[c] | 45 (1S,2S,5R) 46 (1S,2S,5R) |

| 5 pH 6 6 pH 7 | IPR E238Y IPR E238Y | 1 b 1 b | 2 d 2 d | 33[d] 47[d] | 47 (1R,2S,5S) rac |

| 7 pH 7 | MNMR Y244E | 5 c | 6 c | 3 | nd |

[a] Reactions (1 mL) were performed in buffer (50 mm KH2PO4 pH 6.0 for IPR; 50 mm Tris pH 7.0 for MNMR and IPR) containing monoterpenoid (1 a,b, 3 a,b, and 5 a–d; 5 mm), enzyme (5 μm or 10 μm for IPR and MNMR, respectively), NADP+ (10 μm), glucose (15 mm), GDH (10 U), and enzyme (2 μm). The reaction solutions were agitated at 25 °C for 24 h at 130 rpm. Product identification was performed by both comparing retention times with authentic standards and identification by GCMS on a DB‐WAX column (only GCMS identification for product 8 a). Figure S10 gives the GCMS spectra traces of the additional products and their respective substrates. [b] Product yield and enantiomeric excess were determined by GC analysis using DB‐WAX and Chirasil‐DEX‐CB columns, respectively. nd=not determined due to low product yield. [c] Other isomer formed (20 % yield) was 2 a. [d] Other isomer formed (2 % yield) was 2 c.