Abstract

This article reports the first publicly available egg production costs compared across 3 hen-housing systems. We collected detailed data from 2 flock cycles from a commercial egg farm operating a conventional barn, an aviary, and an enriched colony system at the same location. The farm employed the same operational and accounting procedures for each housing system. Results provide clear evidence that egg production costs are much higher for the aviary system than the other 2 housing systems. Feed costs per dozen eggs are somewhat higher for the aviary and lower for the enriched house compared with the conventional house. Labor costs are much lower for the conventional house than the other 2, and pullet costs are much higher for the aviary. Energy and miscellaneous costs are a minimal part of total operating costs and do not differ by housing system. Total capital investments per hen-capacity are much higher for the aviary and the enriched house. Capital costs per dozen eggs depend on assumptions about appropriate interest and depreciation rates. Using the same 10% rate for each housing system shows capital costs per dozen for the aviary and the enriched housing system are much higher than capital costs per dozen for the conventional house. The aviary has average operating costs (feed, labor, pullet, energy, and miscellaneous costs that recur for each flock and vary with egg production) about 23% higher and average total costs about 36% higher compared with the conventional house. The enriched housing system has average operating costs only about 4% higher compared with the conventional house, but average total costs are 13% higher than for the conventional house.

Keywords: egg-laying cost, hen housing system, sustainable egg production

INTRODUCTION

Farmers in the United States face demands from buyers and policymakers to adjust production practices. Laws and buyer standards that require new rules for housing egg-laying hens reflect these demands. For example, under California law, starting in 2015 egg producers must meet criteria that will eliminate the use of conventional cages for eggs sold in the state (State of California, 2010). Likewise, several national restaurant firms have established rules or schedules for transitioning to new housing standards for egg-laying hens (Cone, 2012).

New standards have costs, and data on the magnitude and source of added costs are difficult to gather. Only a few studies have examined costs associated with alternative production systems. The expansion of living space for hens increases production costs and must command market premiums to be competitive when buyers have a choice (Patterson et al., 2001; Sumner et al., 2008, 2010, 2011; Lusk and Norwood, 2011; Mench et al., 2011; Norwood and Lusk, 2011). Most noncage eggs are produced in floor systems in the United States. Sumner et al. (2008) reviewed several data sources and reported on data from California producers.

This article reports the best available cost comparisons across housing systems. The data represent the first on-farm cost comparisons across 3 housing systems used by a single farm, at the same location, employing the same accounting system for each housing system.

The findings reported here come from data collected at a commercial egg farm that was managed to facilitate several scientific research experiments over 2 flock cycles. Farm managers provided specific cost of production data measured in real time during commercial operations over the laying cycles. Each of the 2 flocks was divided among 3 housing systems: (1) a conventional cage house, (2) an enriched colony house, and (3) a cage-free aviary house. We used the economic data to compare feed costs, labor costs, pullet costs, calculated energy costs, capital costs, miscellaneous operating costs, and the sum of all available costs across the 3 housing systems.

Each house was stocked with the same breed of pullets and generally managed similarly given the difference in housing. Other than using the same pullet breed for each house, the houses were managed as commercial operations.

MATERIALS AND METHODS

Housing Systems

Conventional House

The belted, preexisting conventional house has a stocking capacity of 199,680 hens. The conventional house consisted of 10 rows of cages with 8 tiers and a walkway between tiers 4 and 5. Each tier contained 416 identical back-to-back cages. The conventional cage provided 516.13 cm2 (80 in2) per bird with 6 birds per cage. The house was tunnel ventilated and had manure removed every 3 to 4 d (Zhao et al., 2014).

Cage-Free Aviary

The cage-free aviary system (aviary) was a newly built facility and has a housing capacity of 50,000 laying hens. Hens were distributed in 6 colony rows with each row divided by wire mesh screens into 10 pens along the building length. Hens had access to 10.19 cm (4.01 in) of feeder space, 15.24 cm (6 in) of perch space, and 86.32 cm2 (13.38 in2) of nest space area (Zhao et al., 2014).

Enriched Colony

The enriched colony house was a belted, newly built facility with a housing capacity for 46,800 laying hens. The facility consisted of 5 rows of colony cages with 4 tiers per row. Each enriched colony cage contained 60 birds that provided 753.22 cm2 (116.75 in2) of physical space. Each colony cage provided several amenities (expressed on a per bird basis), including 12.07 cm (4.75 in) of feeder space, 17.73 cm (6.98 in) of perch space, 63.03 cm2 (9.77 in2) of nest space, and 26.52 cm2 (4.11 in2) of scratch pad space. The house had ceiling inlets and was cross-ventilated with manure removal every 3 to 4 d (Zhao et al., 2014).

Egg Production Cost Data

The farm manager provided data related to pullets, feed, labor, and capital costs for each of the housing systems. Costs of energy consumption and share of farm level miscellaneous costs were calculated for each house. Weekly production data included the amount of feed consumed, the amount of water consumed, number of eggs produced, current hen population, weekly mortality, BW of hens, and manure produced for each of the 3 housing systems.

Table 1 reports the list of data available for analysis. The farm managers provided data items weekly, biweekly (every two weeks), and monthly where appropriate. The pullet, energy, and miscellaneous cost data applied once per flock and the initial capital investment applied to the whole period. We describe the available data before turning to our analysis that allowed calculation of itemized costs per dozen eggs for each housing system.

Table 1.

List of production and cost data available per housing system.

| Variable categories reported separately by housing system | Frequency of measurement |

|---|---|

| Capital cost data | |

| Area of each housing system | Once |

| Real estate cost of land to build housing system | Once |

| Initial cost to build and housing system | Once |

| Pullet cost data | |

| Price per pullet and number of pullets | Once per flock |

| Feed data | |

| List of feed mix ingredients | Monthly |

| Pounds of feed ingredient used per ton of mix | |

| (feed ingredients: corn, soybean meal DDG,1 and others) | Monthly |

| Price per pound of feed ingredient | Monthly |

| Total price per ton of feed mix | Monthly |

| Total monthly pounds consumed per housing system | Monthly |

| Total cost of feed consumed per housing system | Monthly |

| Labor data | |

| Average wage rate for nonmanagement workers | Biweekly |

| Total nonmanagement worker hours per housing system | Biweekly |

| Nonmanagement hours for feed distribution | Biweekly |

| Nonmanagement hours for manure and litter | Biweekly |

| Nonmanagement hours for equipment maintenance | Biweekly |

| Nonmanagement hours for egg collection | Biweekly |

| Nonmanagement hours for hen health issues | Biweekly |

| Nonmanagement hours for house keeping | Biweekly |

| Average wage rate for management workers | Biweekly |

| Total management hours | Biweekly |

| Energy data2 | |

| Electricity consumption | Monthly |

| Propane consumption | Monthly |

| Miscellaneous cost3 | |

| Farm-level miscellaneous | Once per flock |

| Production data | |

| Total pounds of feed consumed | Weekly |

| Total gallons of water consumed | Weekly |

| Dozens of eggs produced | Weekly |

| Case weight of eggs | Weekly |

| Mortality and culls | Weekly |

| Total mortality | Weekly |

| Number of hens currently in housing system | Weekly |

Distillers dried grains.

The farm monitors energy costs on a farm-level basis. Electricity and propane consumption data were collected across the 3 housing systems as part of the overall study (Zhao et al., 2014). Energy costs were estimated using electricity and propane consumption data and applying the corresponding market price per unit to each.

The farm record miscellaneous costs for the entire farm for the duration of each flock. To assign miscellaneous costs to each housing system, total farm-level miscellaneous costs are divided by total farm hen population. The share of miscellaneous costs per housing unit is equal to the share of total hen population within each housing unit.

Capital Cost Data

Information supplied included the area used for each house including the footprint of the barn and other associated space. This area requirement generated land costs for each housing system. The other capital cost included the initial cost to build each house and the equipment investment in each house. The conventional house was constructed in 2004, 7 yr before the 2011 construction of the aviary and enriched houses. We adjusted conventional house capital costs to the equivalent 2011 costs in our analysis. Information on interest rates, expected life of barn or equipment, and expected depreciation was not available.

Pullet Cost Data

Pullets were purchased from a commercial hatchery and housed on site in conventional cages or cage-free aviary rearing systems. Pullets reared in a conventional cage system were destined for the conventional house or enriched cage house. Pullets in the conventional cages were provided 247.74 cm2 (38.4 in2) with 15 birds per cage. The aviary rearing system had 218 birds per cage with 159.94 cm2 (24.79 in2) of cage space, 2.18 cm (0.86 in) of perch space, and 4.37 cm (1.72 in) of feeder space per bird. From 9 to 18 wk, the aviary pullets had additional cage space provided, increasing the total cage space available by 248.97 cm2 (38.59 in2) and 1.09 cm (0.43 in) of perch space. Aviary pullets also had floor access from 6 to 18 wk, providing 100.13 cm2 (15.52 in2) per bird. The pullets were moved at 19 wk of age into the 3 different housing systems. The total number of pullets entering each laying house and the cost per pullet entering the laying house were used to calculate total pullet cost for each housing system. The cost per pullet entering the laying house was provided by the farm manager and includes the original price of each purchased pullet plus operating and capital costs of maintaining pullets in the rearing house before entering the laying house. Total pullet costs for each housing system were then divided by the total egg production over the 60-wk laying cycle to estimate the pullet costs per dozen eggs produced for each of the 2 flocks.

Feed Cost Data

The farm purchased feed ingredients in bulk each month and mixed the ingredients on site to the specifications of the farm manager. Feed was independently formulated for each housing system based on egg production level, feed consumption, and ingredient cost. Main feed ingredients include corn, soybean meal, and distillers dried grains (DDG). Many additional feeds and supplements were added to the ration, but had relatively low cost shares. The farm provided feed mix rations by house and specific feed ingredient costs for each month. With these data, we calculated cost per unit of feed mix for each month and applied this cost to the egg production for the appropriate weeks.

Labor Cost Data

The farm recorded the hourly wage rate and hours of nonmanagement labor for specific egg production tasks for each housing system. The tasks included feed distribution, manure and litter management, equipment maintenance and repair, egg collection, hen health issues, and general housekeeping. Because all eggs produced during the research period were sold as breakers and not in-shell eggs, the farm used no labor for egg packaging. We calculated labor costs for each of the production tasks by multiplying the hours per task by an average hourly wage rate. The farm allocated management labor and the management salaries to each house. We added management labor cost to hourly worker costs to calculate total labor costs for each period for each house.

Energy Cost and Miscellaneous Cost Data

The quantity of electricity and propane consumed by each house was measured for both flocks as part of the overall collaborative research. We applied the applicable local price per unit for both electricity and propane to total consumption to calculate energy costs. Miscellaneous operating costs were provided at the farm level. We used the share value of each house's hen population to total farm hen population to assign total farm miscellaneous cost share to each house.

RESULTS AND DISCUSSION

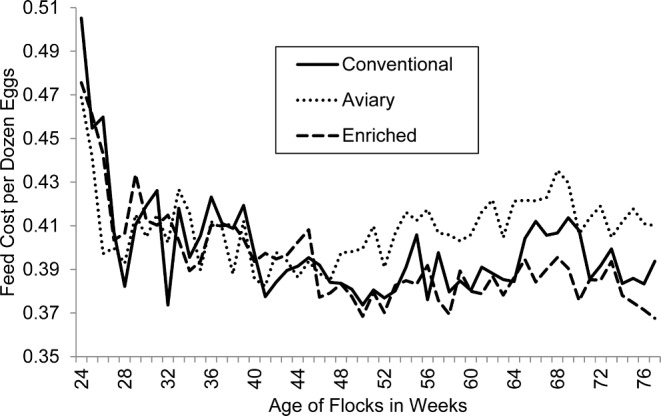

Feed costs are by far the largest cost item in egg production, especially for conventional housing systems. The bulk of the feed costs derive from corn, soybean meal, and DDG, in that order. Figure 1 shows the average over the 2 flocks of feed costs per week per dozen eggs. Feed cost variations reflect several contributing factors. First, the prices of corn, soybeans, and DDG vary over the period of investigation and the costs reflect those market price variations. Second, the amount of feed per bird and the average egg production per bird vary over the life of a flock. Finally, feed waste and feed usage per bird vary across housing system. Figure 1 shows the rapid decline in feed cost per dozen eggs at the start of the cycle and a gradual rise at the end of the cycle. Feed costs per dozen eggs rise more over the cycle for the aviary compared with the other 2 systems. The greater rise in feed cost per dozen eggs in the aviary house is primarily due to a decrease in egg production per hen. On average over the 2 flocks, hens in the enriched housing system produced about 1.5% more eggs per pound of feed consumed than hens in the conventional housing system. The greater number of eggs per hen in the enriched housing system is a topic of ongoing research among poultry production specialists.

Figure 1.

Average weekly feed costs per dozen eggs by housing system (both flocks).

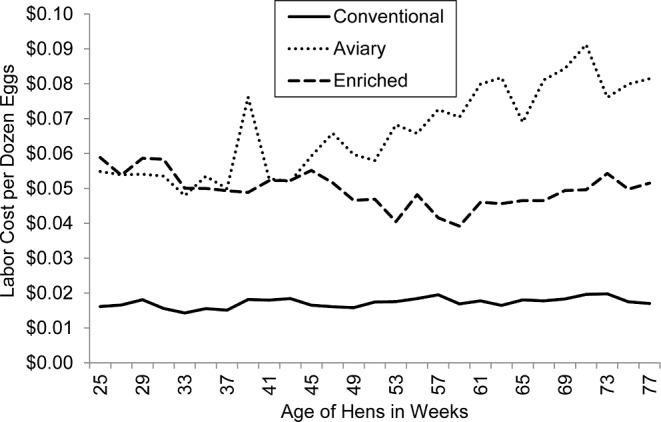

Figure 2 displays every two weeks labor cost per dozen eggs. For the conventional house labor costs contribute about 2 cents per dozen with little change over the life cycle of the flock. These costs include management time, which is spread over a large flock of birds in the conventional house. Labor costs for the aviary increase over the life cycle and are variable from period to period. The average labor cost increases from about 6 cents per dozen to more than 8 cents per dozen. The largest specific labor cost item for the aviary is egg collection, which increases steadily to over 3 cents per dozen for the last half of the cycle. In the aviary, workers must collect floor eggs, or eggs laid outside of the nest box, collect dead or dying hens, and generally deal with a more dispersed area for hen care, which is time consuming and becomes more difficult as the laying cycle progresses. In addition, hen mortality and other hen health issues are greater in the aviary system and contribute to the higher labor costs. Egg collection is a small cost item in both of the caged systems. The enriched housing system had costs between the 2 extremes, averaging more than 5 cents per dozen. The enriched housing system exhibited higher management labor costs than the conventional house primarily because it used the same management hours for fewer hens. In each of the other specific cost items, costs were relatively higher for the aviary and the enriched houses. Housekeeping, feed distribution, and hen health issues all entailed more costs per dozen for the 2 alternatives compared with the conventional house.

Figure 2.

Average every two weeks labor costs per dozen eggs produced by housing system.

Pullet costs also differ significantly between the aviary and the other 2 housing systems. The 3 houses used the same breed of hen over the 2 flock cycles. The cost of pullets entering each house differed for the aviary housing system compared with the enriched and conventional housing systems due to differences in rearing costs. The pullets entering the conventional cage system and the enriched system were reared in the same conditions. The aviary pullets needed to be acculturated to the aviary system and, therefore, reared in an aviary rearing barn, which is more expensive. Itemized rearing cost data were not collected. Table 2 shows calculations for pullet costs per dozen eggs. The aviary pullets cost about $1.85 more per bird than the birds entering the conventional and enriched cage houses. Furthermore, the aviary birds produce about 5% fewer eggs per pullet than the birds in the conventional system. The aviary system begins with the same number of eggs per hen in the initial weeks, but egg production falls much more steeply for the aviary (not shown in the table). Hen mortality is higher in the aviary. By the end of the cycle, the flocks in the aviary system lost 13.3% of the original pullets placed in the barn, compared with 5.2% mortality in the enriched cage system and 4.8% in the conventional system. Also by the end of the cycle, eggs per pullet for the aviary fell to about 10% below the average in the conventional house and 15% below the average in the enriched house.

Table 2.

Average pullet costs per dozen eggs produced.

| Item | Conventional | Aviary | Enriched |

|---|---|---|---|

| Average number of pullets purchased per flock | 196,128 | 49,760 | 46,669 |

| Average cost per pullet1 (%) | 4.48 | 6.33 | 4.48 |

| Total pullet cost (%) | 879,556 | 314,917 | 209,290 |

| Total dozen eggs produced | 5,928,337 | 1,423,795 | 1,457,964 |

| Dozen eggs produced per pullet | 30.2 | 28.6 | 31.2 |

| Pullet cost per dozen eggs (%) | 0.148 | 0.221 | 0.143 |

All pullets were the same breed. Pullets for the conventional and enriched cage housing systems were reared in the same house; therefore, the cost per pullet was the same. Pullets for the aviary housing system were reared in a pullet house specific for aviary hens and were more costly.

The price per pullet was the same for the conventional and enriched cage houses. The enriched house has about 3.3% higher average eggs per pullet than the conventional house and a 2.7% lower pullet cost per dozen eggs produced.

Table 3 shows a calculation of capital costs per dozen eggs using data from the farm and some simple standard assumptions about interest and depreciation rates. We show the itemized capital outlay for land, building, and equipment, and the sum of capital invested for each house in the top rows of Table 3. Because the conventional house was built in 2004, whereas the aviary and enriched cage houses were built in 2011, we accounted for the time difference by converting the original capital outlay for the conventional house to 2011 prices using standard price indexes. Land costs, including the yard and required area surrounding each house, make up less than 1% of capital costs, with building costs and equipment making up more than 99% of costs. The conventional facility had equivalent capital costs of $2.97 million compared with $1.96 million for the aviary system and $1.49 million for the enriched system.

Table 3.

Land and facility capital costs by housing system.

| Item | Conventional1 | Aviary | Enriched |

|---|---|---|---|

| Capital outlay ($ million) | |||

| Land | 0.02 | 0.01 | 0.01 |

| House construction | 0.99 | 1.22 | 0.86 |

| Equipment | 1.96 | 0.73 | 0.62 |

| Total | 2.97 | 1.96 | 1.49 |

| Annualized cost of capital outlays at constant interest plus depreciation (%) | |||

| 5% (interest + depreciation) | 148,500 | 98,000 | 74,500 |

| 10% (interest + depreciation) | 297,000 | 196,000 | 149,000 |

| Average eggs per year at an average of 51 wk of laying (dozen eggs) | |||

| Eggs for 51 wk production | 5,079,500 | 1,212,900 | 1,243,500 |

| Annualized cost of capital outlays per dozen eggs (%) | |||

| 5% (interest + depreciation) | 0.029 | 0.081 | 0.060 |

| 10% (interest + depreciation) | 0.058 | 0.162 | 0.120 |

The conventional house was built in 2004. We adjusted land, construction, and equipment costs for price changes to their equivalent 2011 values using national producer price index for building construction and farm equipment and local price data for changes in land value.

We converted capital costs into an equivalent annual flow using 2 alternative assumptions about the applicable rate of interest and depreciation. The same rate was used for all 3 houses. These assumptions are within standard ranges often used in investment calculations but were not derived from the cost accounts provided by the farm.

Several considerations are useful in considering these rates at which the capital costs are converted to annual cost flows. First, the applicable interest rate (or discount rate) for an investment depends on the risk to the income generated and the potential for significant losses. Different investors could have different views about how risky investments in the 3 housing systems are likely to be. Second, depreciation may differ across the housing systems relating especially to the equipment installed. A further difference relates to the rate at which the invested capital may become obsolete due either to technical improvement or changes in flock management. If, for example, enriched housing systems were expected to improve rapidly, then the investment may be replaced sooner and this expected change plays the same role as a higher depreciation rate. Similarly, if capital equipment is likely to be replaced sooner, the investor would demand a higher interest rate or rate of return to reflect the shorter pay-back period for the investment.

Because the interest and depreciation calculations are typically considered on an annual basis, we calculated the average number of eggs produced per year of operations. We used weekly data from the 60-wk active lifecycle of each flock and assumed the house produces eggs for 51 wk per year (about 8 d per flock for transition). Using the egg production data noted in Table 2, the conventional house, with about 4 times the number of hens, produces about 5,079,500 dozen eggs per year compared with about 1,212,900 dozen for the aviary and 1,243,500 dozen for the enriched housing system.

Finally, rows 2 and 3 can be converted to a flow of costs per dozen to place capital costs on a comparable basis with the operating costs. Using the 10% rate of interest plus depreciation, capital costs are about $0.058 per dozen for the conventional house, about $0.162 per dozen for the aviary, and about $0.120 per dozen for the enriched housing system.

We now have the ingredients to compare costs across the 3 housing systems. Table 4 provides average operating and capital cost per dozen eggs calculations for both flocks. Feed costs are higher for the aviary by 2.6% compared with the conventional house and slightly lower for the enriched housing system. So, even though feed is by far the largest cost component, it is not the source of major differences in costs across the housing systems. Labor, a much smaller share of costs, makes up a larger share of the differences. The aviary and the enriched housing system both have higher costs of more than 4 cents per dozen—more than triple the labor use compared with the conventional house. Cost differences across houses derive from more labor per dozen eggs because wage rates are the same for each house.

Table 4.

Average operating and capital costs per dozen eggs for each housing system

| Item | Conventional | Aviary | Enriched |

|---|---|---|---|

| Feed cost ($) | 0.425 | 0.436 | 0.417 |

| Pullet cost ($) | 0.148 | 0.221 | 0.143 |

| Labor cost ($) | 0.019 | 0.074 | 0.056 |

| Energy cost ($) | 0.014 | 0.015 | 0.014 |

| Miscellaneous cost ($) | 0.005 | 0.005 | 0.005 |

| Sum of operating costs ($) | 0.612 | 0.751 | 0.636 |

| Percentage higher operating costs compared with conventional | — | 23 | 4 |

| Capital costs (at 10%; $) | 0.058 | 0.162 | 0.120 |

| Capital + operating ($) | 0.670 | 0.913 | 0.756 |

| Percentage higher costs compared with conventional | — | 36 | 13 |

Pullet costs also differ substantially, and the data in Table 4 provide a summary by flock of the information detailed in Table 2. Energy costs and miscellaneous costs were only a small share of total operating costs for each of the 3 houses with practically no difference across the 3. Table 4 also provides a sum of operating costs per dozen eggs. On average across the 2 flocks, operating costs were almost $0.139 (24%) higher for the aviary compared with the conventional house. Operating costs were only $0.024 (about 4%) higher for the enriched system compared with the conventional system. Higher labor costs offset lower feed costs.

As we saw in Table 3, capital costs are much lower for the conventional housing system. The bottom line of Table 4 indicates total capital outlay per dozen eggs is $0.104 (180%) higher for the aviary and $0.062 (107%) higher for the enriched system compared with the conventional housing system. The aviary is the most costly system for all cost categories. Costs of the enriched system are quite similar to those of the conventional system except for the labor and capital costs, which are considerably higher.

A few overview comments may be useful as a conclusion. These results derive from the first systematic comparison of costs across system operations by one farm using the same management and accounting system. These costs provide an industry benchmark. The results provide clear evidence that costs at the farm are much higher for the aviary system, and capital investments per hen and per dozen eggs are the main source of higher costs for the enriched system.

In this paper, we do not have data on post-farm costs or on consumer prices. Our farm cost estimates derive from the operations of a commercial firm. That said, the experimental design did not allow for full optimization of management practices. For example, the farm may use a different pullet breed, which could dictate different feed rations in each house when free to operate to achieve optimal results. We plan to collect similar cost data from the 3 houses for at least one flock under purely commercial operation.

Footnotes

Research support provided in part by a grant from the Coalition for a Sustainable Egg Supply (Kansas City, MO).

Member of the Giannini Foundation Davis, California.

REFERENCES

- Cone T. Burger King Makes Cage-Free Eggs, Pork Promise. Associated Press News Service; 2012. April 26, 2012, Accessed http://infoweb.newsbank.com/iw-search/we/InfoWeb/?p_action=explore&d_search_type=keyword&d_sources=location&d_place=world&d_issuesearch=&f_clearSearch=yes&d_issuesearch=&p_product=AWNB&p_theme=aggregated4&p_nbid=X55K52RIMTQxMDUzODU3OC45NzcxMzg6MToxNToxNjkuMjM3LjIzMi4yMTU. Apr. 22, 2014. [Google Scholar]

- Lusk J. L., Norwood F. B. Animal welfare economics. Applied Economic Perspectives and Policy. 2011;33:463–483. [Google Scholar]

- Mench J. A., Sumner D. A., Rosen-Molina J. T. Sustainability of egg production in the United States—The policy and market context. Poult. Sci. 2011;90:229–240. doi: 10.3382/ps.2010-00844. [DOI] [PubMed] [Google Scholar]

- Norwood F. B., Lusk J. L. Compassion, by the Pound: The Economics of Farm Animal Welfare. New York, NY: Oxford University Press; 2011. [Google Scholar]

- Patterson P., Koelkebeck K., Bell D., Carey J., Anderson K., Darre M. Egg marketing in national supermarkets: Specialty eggs. Part 2. Poult. Sci. 2001;80:390–395. doi: 10.1093/ps/80.4.390. [DOI] [PubMed] [Google Scholar]

- State of California. Health and safety code. Division 20. 2010. Chapter 13.8, Section 25990–25994. [Google Scholar]

- Sumner D. A., Gow H., Hayes D., Matthews W. A., Norwood B., Rosen-Molina J. T., Thurman W. Economic and market issues on the sustainability of egg production in the United States: Analysis of alternative production systems. Poult. Sci. 2011;90:241–250. doi: 10.3382/ps.2010-00822. [DOI] [PubMed] [Google Scholar]

- Sumner D. A., Matthews W. A., Mench J. A., Rosen-Molina J. T. The economics of regulations on hen housing in California. Journal of Agricultural and Applied Economics. 2010;42:429–438. [Google Scholar]

- Sumner D. A., Rosen-Molina J. T., Matthews W. A., Mench J. A., Richter K. University of California Agricultural Issues Center; 2008. Economic effects of proposed restrictions on egg-laying hen housing in California. Accessed Nov. 2009, http://aic.ucdavis.edu/publications/eggs/egg_initiative.htm. [Google Scholar]

- Zhao Y., Shepherd T. A., Swanson J., Mench J. A., Karcher D. M., Xin H. Comparative Evaluation of Three Egg Production Systems: Housing Characteristics and Management Practices. Poult. Sci. 2014;94:475–484. doi: 10.3382/ps/peu077. [DOI] [PMC free article] [PubMed] [Google Scholar]