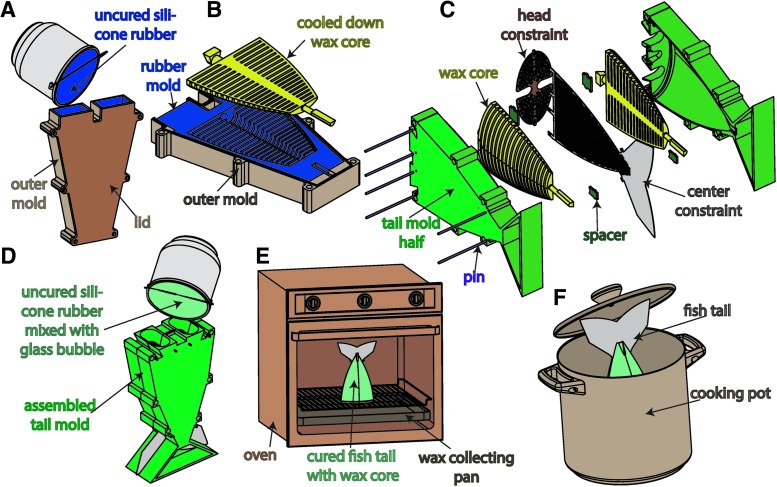

FIG. 15.

Fish tail fabrication process: (A) pour and cure a rubber mold; (B) pour wax cores; (C) combine head constraint, center constraint, and wax cores with tail mold halves; (D) pour rubber mixed with glass bubbles into assembled tail mold; (E) using an oven melt out wax core from the cured fish tail; and (F) cook out remaining wax to create desired actuator cavities.