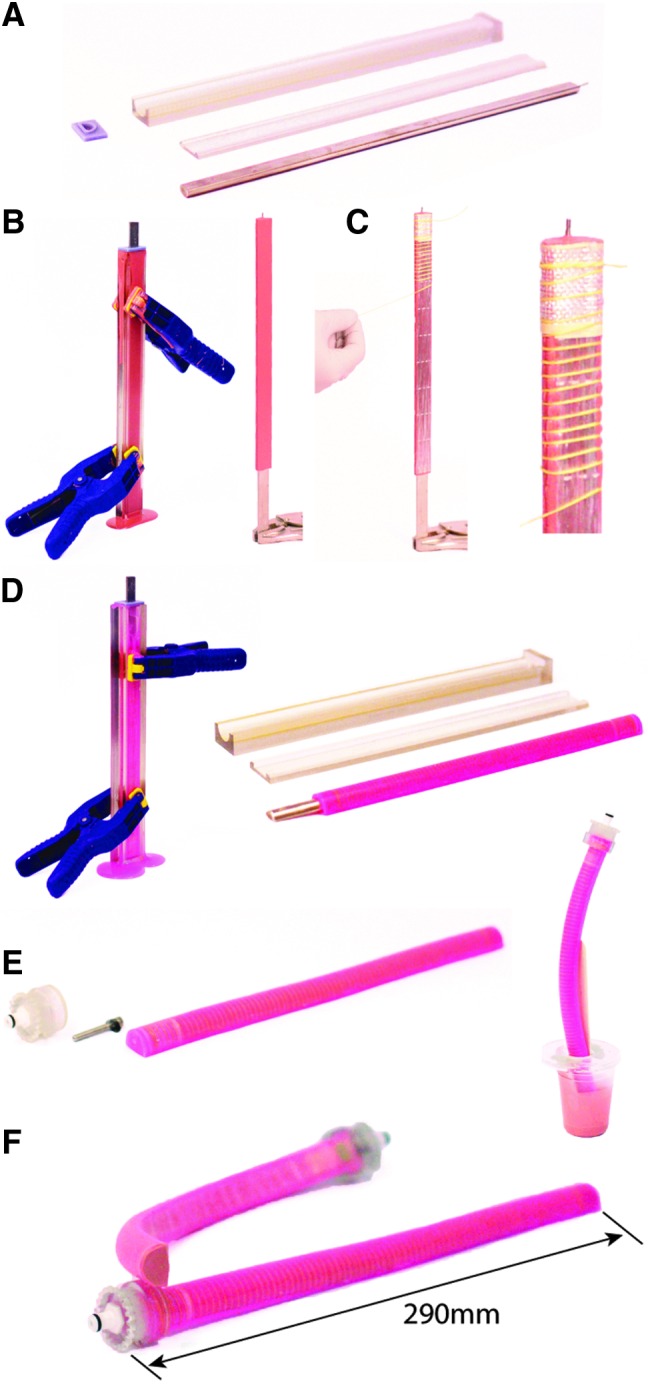

FIG. 7.

Schematic diagram outlining the stages of the boa-type actuator fabrication process. (A) The actuator bladder is molded using 3D-printed molds and the internal geometry is formed with a half-round steel rod. (B) Liquid polymer (M4601 by Wacker Chemical, Inc.) is poured into the clamped mold and the half-round rod is inserted into the center. The polymer is cured and removed from the mold. (C) Strain-limiting materials (i.e., fiber reinforcements) are applied to the exterior of the bladder. (D) The fiber-reinforced bladder is inserted into a second mold filled with liquid polymer (Dragon Skin 20 by Smooth On) to add a thin skin (∼1 mm thick) around the actuator body to hold the strain-limiting materials in place. The actuator body is then removed from the mold. (E) The half-round rod is removed and coupling hardware is installed on one end of the actuator. The other end of the actuator is sealed with more polymer. (F) Excess polymer is trimmed from the end and the actuator is complete. Color images available online at www.liebertpub.com/soro