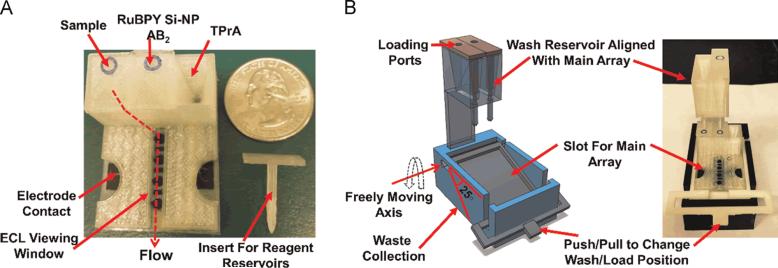

Figure 4.

FDM-printed devices that enable gravity-flow reagent and washing buffer delivery for ECL-based immunoassays. (A) A screen-printed electrode array is affixed to the bottom of a 3D-printed reagent delivery system. Serum sample, antibody (AB2)-labeled silica nanoparticles (Si-NP) filled with ECL dye Ru(bpy)32+, and ECL coreactant tri-n-propylamine are stored in reservoirs. Delivery of reagents to the open-top channel is accomplished by removing reservoir inserts. B) 3D model (left) and photograph of wash reservoir module showing freely moving lever to change between wash and load positions. A lever is used to adjust the position of the array so that reagents or washing buffer can be held on the electrode array surface for incubation or flowed over for washing. Reprinted from Reference 43 with permission from Elsevier.