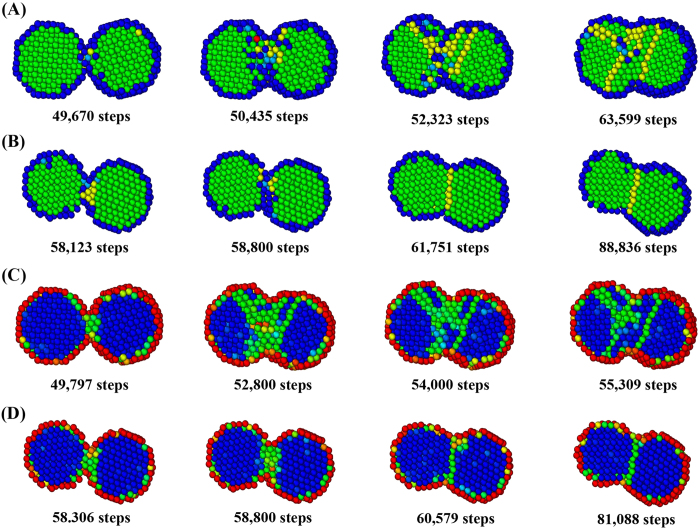

Figure 9. Comparison of various measures for the quality of cold welding.

(A) Ackland-Jones parameter contour in M model, (B) Ackland-Jones parameter contour in N model, (C) Centro-symmetry parameter contour in M model, (D) Centro-symmetry parameter contour in N model. Bcc and hcp structures (A) and stacking faults (C) are expanding from the welding surface as the cold welding progresses in M model. After some relaxation period, fcc structure is finally recovered. On the other hand, a small portion of hcp structures (B) and stacking faults (D) near the welding surface are generated around the welding surface as the cold welding progresses in N model. After some relaxation period, the fcc structure is quickly recovered. The region of atomic diffusion is very limited, which could lead to incomplete welding.