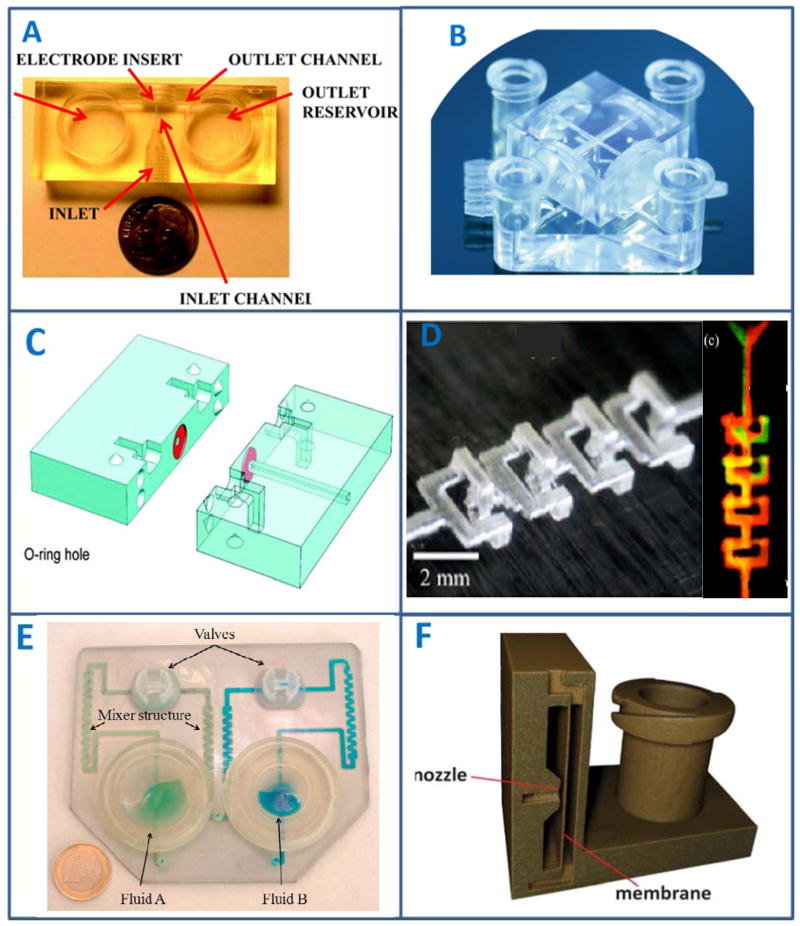

Figure 3.

Examples of unique features that can be realized by 3D-printing. (A), a 3D-printed microfluidic device with wall-jet electrochemical configuration. Threaded ports that fit commercial finger tight adapters were 3D-printed on the device. A sample can be introduced through the inlet, which then hits the electrode housed in the “electrode insert” to achieve wall-jet detection. (Adapted from ref. 19 with permission from The Royal Society of Chemistry) (B), luer adapters were 3D-printed on a microfluidic device for easy connection with tubing and syringes. (Adapted from ref. 40 with permission from John Wiley & Sons, Inc) (C), O-rings can be 3D-printed with rubber-like materials on a fluidic device. In this example, the authors used the printed O-ring to connect different chips. (Adapted from ref. 41 with permission from The Royal Society of Chemistry) (D), A 3D-printed gradient generator. With 3D-printing, complicated channels were fabricated in this example. (Adapted from ref. 42 with permission from The American Chemical Society) (E), A 3D-printed microfluidic mixer. By fabricating zigzag channels and vales, two liquids can be mixed well using the device. (Adapted from ref. 44 with permission from Elsevier) (F), A 3D-printed pneumatic valve. The “membrane” is a thin layer (~200 μm) of 3D-printed structure. When proper air pressure is applied through the nozzle, the membrane can deform to open or close the channel on the right side. (Adapted from ref. 43 with permission from The Royal Society of Chemistry)