Table 1.

Examples of bioaugmentation of industrial wastewaters for the remediation of important organic compounds.

| Pollutant | Set Up | Medium for Bioaugmentation | Bioaugmented Bacteria | Ref. | |

|---|---|---|---|---|---|

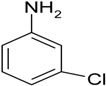

| 3-Chloroaniline |  |

Semi-continuous activated sludge (SCAS) (1 L) | Synthetic influent consisting of skim milk powder | Comamonas testosteroni | [19] |

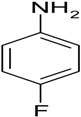

| 4-Fluoroaniline |  |

Batch reactor (BR) (250 mL) | Inorganic salt medium | Acinetobacter sp. | [20] |

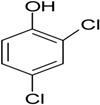

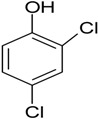

| 2,4-Dichlorophenol (2,4-DCP) |  |

Laboratory-scale continuous flow complete-mixed reactors (CFSTRs) (16 L) | Synthetic wastewater (SW) | Consortium of bacteria | [21] |

| 2,4,6-Trichloro-phenol |  |

fluidized bed biofilm reactor (FBBR) and expanded granular sludge bed (EGSB) | Industrial wastewater (IW) | Desulfitobacterium sp. | [22] |

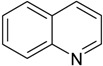

| Quinoline |  |

Sequential Batch reactor (SBR) (250 mL) | Petroleum refinery wastewater | Bacillus sp. | [27] |

| Quinoline | SBR (2–7 L) | Coke plant wastewater | Burkholderia pickettii | [28] | |

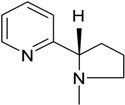

| Pyridine and quinoline |  |

BR (100 mL) | Inorganic medium and wastewater | Paracoccus sp. and Pseudomonas sp. | [29] |

| Quinoline and Pyridine | BR (250 mL) with modified zeolite | Coke wastewater | Paracoccus sp. and Pseudomonas sp. | [30] | |

| Quinoline and Pyridine | SBR | Coke wastewater | Consortium of Paracoccus sp. BW001, Shinella Zoogloeoids BC026, Pseudomonas sp. BC001 and BW003, | [31] | |

| Pyridine | SBR | Industrial wastewater | Rhizobium sp. | [33] | |

| Pyridine | 2 Membrane Bioreactors (MBR, 25 L each) | Pharmaceutical Wastewater | Paracoccus denitrificans | ||

| Acid Orange 7 dye |  |

Membrane-aerated biofilm reactor (MABR) (2 L) | SW | Shewanella sp. XB | [37] |

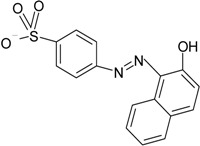

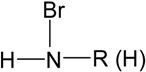

| Bromoamine |  |

MBR 10 L | SW | Sphingomonas xenophaga | [40] |

| Bromoamine | Combined process of microelectrolysis and biological aerated filter 1–3 L | Wastewater | Sphingomonas sp. | [39] | |

| Bromoamine | BR (250 mL) | Inorganic medium | Sphingomonas xenophaga | [40] | |

| Cyanide |  |

Full scale Cokes wastewater treatment facility (fluidized bed type process) > 3 × 105 L | Cokes wastewater | Cryptococcus humicolus, and Unidentified cyanide-degrading microorganisms | [43] |

| Nicotine |  |

3 reactors of cylindrical shape Height: Bore size of 10:1 (2 L) | Synthetic tobacco wastewater | Acinetobacter sp. | [49] |

| Nicotine | SBR (2 L) | Tobacco wastewater diluted in tap water (7%) (g/mL) | Pseudomonas sp. | [50] | |

| Diethylene glycol butyl ether | SBR (2 L) Full scale Plug flow aerated tank (60,000 L) | Wastewater from silicon plate manufacture plant | Serratia sp. | [52] | |

| |||||

| Lignin (highly complex polymer of phenol) | 2 L BR | Industrial wastewater | Comamonas and Pandoraea (bacteria), and Aspergillus (fungus) | [25] | |

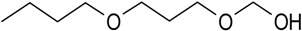

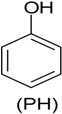

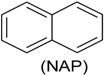

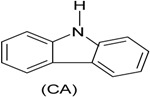

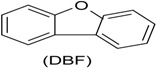

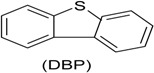

| Phenol (PH) and naphthalene (NAP) along with carbazole (CA), dibenzofuran (DBF), and dibenzothiophene |  |

BR (column of 10 × 50 cm) | Coking wastewater from a treatment plant | Immobilized phenol-utilizing Arthrobacter sp. | [55] |

| |||||

| |||||

| |||||

| |||||

| Naphthalene | MBR (8 L) | Coal gasification wastewater. | Streptomyces sp. | [53] | |

| Mixture of phenol, pyridine, quinoline, naphthalene and carbazole | A sequential system of anaerobic reactor(4.9 L), anoxic reactor, A2 (4.5 L), and an oxic MBR (9 L). MBR (9.0 L) | Coking wastewater | Consortium of 6 bacteria containing Paracoccus Denitrificans and 5 strains of Pseudomonas sp. | [54] | |

| Phenol | Biological contact oxidation reactor (BCOR) | Coal gasification wastewater | Mixture of phenol-degrading bacteria | [56] | |