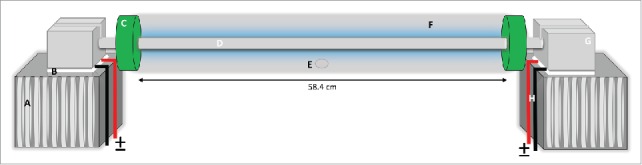

Figure 1.

Artistic rendition of the thermal gradient design. At either end of the aluminum rod, peltier devices were connected and mounted over heat sinks, which were then submerged in circulating water baths. The aluminum rod was encased in a polycarbonate tube and sealed using docking adapters. The desired thermal gradient was created by adjusting the power input to the peltier devices. A=heat sink; B = peltier device; C = polycarbonate tube adapter-connector; D = aluminum rod; E = fly loading aperture; F = plexiglas tube around aluminum rod; G = supporting aluminum adapter block over the peltier device; H = peltier device power cables. For details see methods section. Temperature probes were inserted at following locations- 2.6, 11.7, 20.4, 29.2, 38, 46.7, and 55.8 cm. The diameter of the polycarbonate tube was 6.5 cm. Actual image of apparatus is provided as supplementary file (Supporting file 1).